Gel structure for combined EMI shielding and thermal control of microelectronic assemblies

A technology of electronic components and conductive gel, applied in the direction of magnetic/electric field shielding, electrical components, electric solid devices, etc., can solve the problem of not completely satisfactorily isolating moisture and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

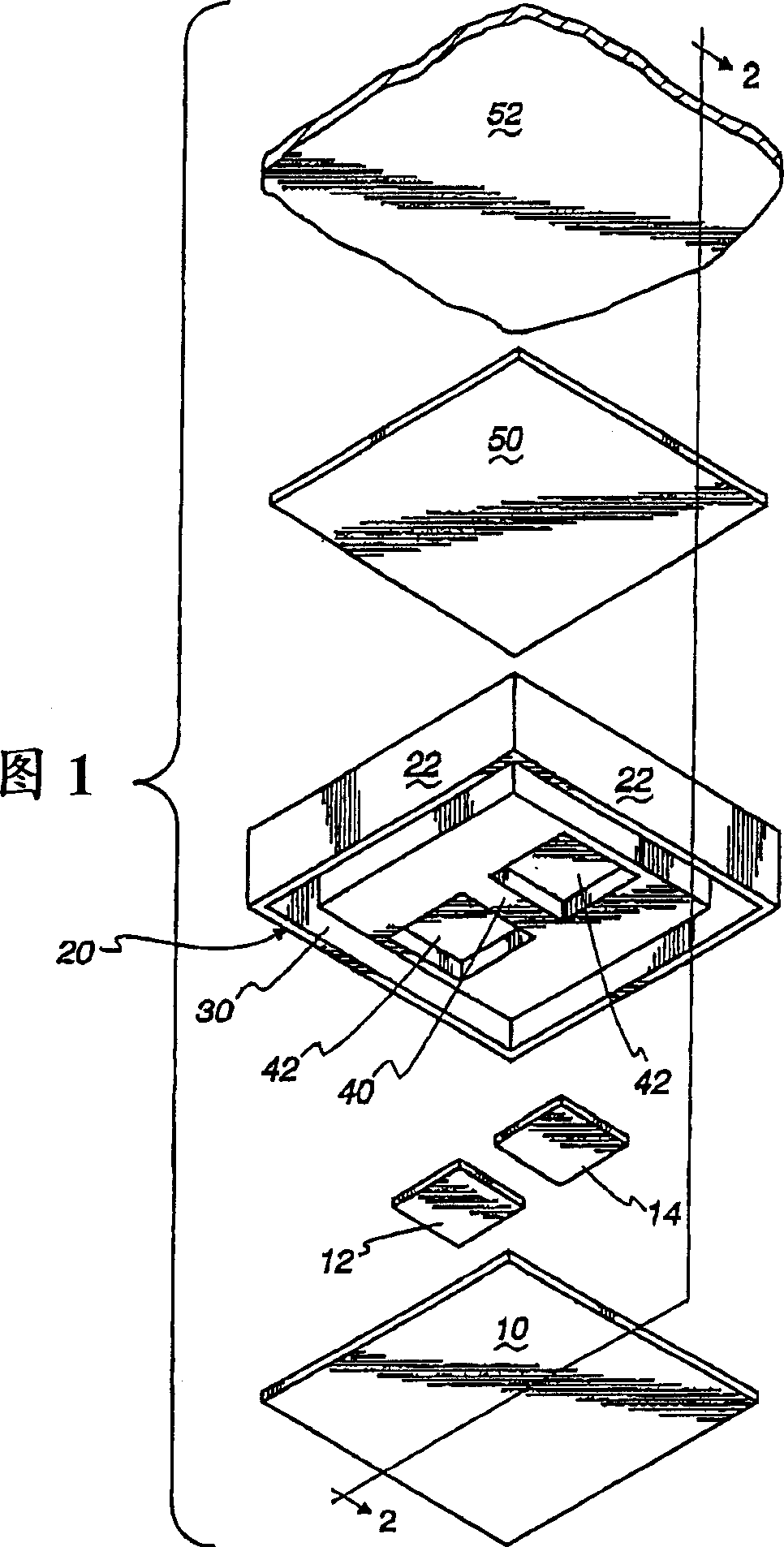

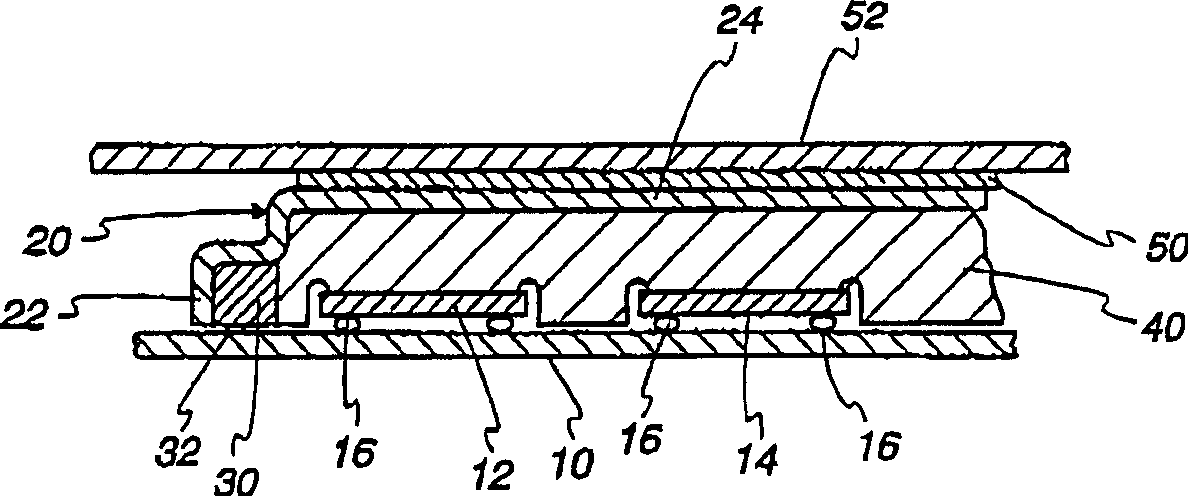

[0021] Figures 1 to 3 show a preferred embodiment of the present invention for use with an electronic assembly that can be used in any electronic device, but is particularly suitable for portable electronic assemblies such as cellular telephones.

[0022] In the illustrated example, a printed circuit board (PCB) 10 is used to suitably connect suitable microcircuit chips 12, 14, such as flip chips or chip scale packages (CSP). Such as figure 2 As shown, the chips 12, 14 are suitably connected to the printed circuit board 10 by a single mechanical connection 16 in the form of solder balls as shown.

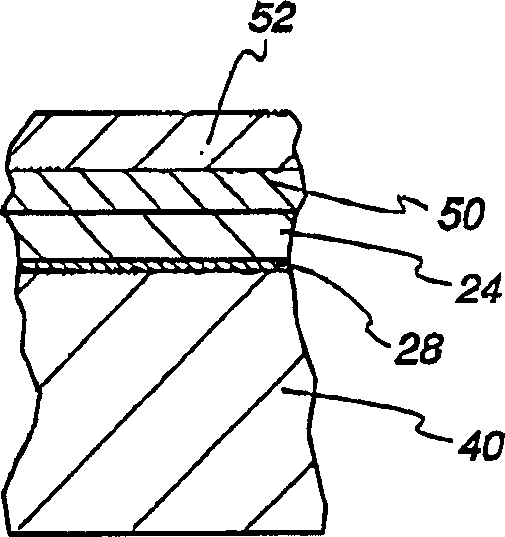

[0023] In the electronic assembly is provided a plastic housing 20 with an outer perimeter 22, one end of the outer perimeter (by figure 2 and 3 The end (defined by the top wall 24 in ) is closed, and the end (the bottom end in the figure) facing the printed circuit board 10 and chips 12, 14 is open. For most applications including, for example, cellular telephones, the plastic h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com