Split type film biological reactor and water treatment method

A technology of membrane bioreactor and bioreactor, applied in the direction of biological water/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problem of high energy consumption in operation, reduce water cycle energy consumption, and be easy to clean , the effect of small energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

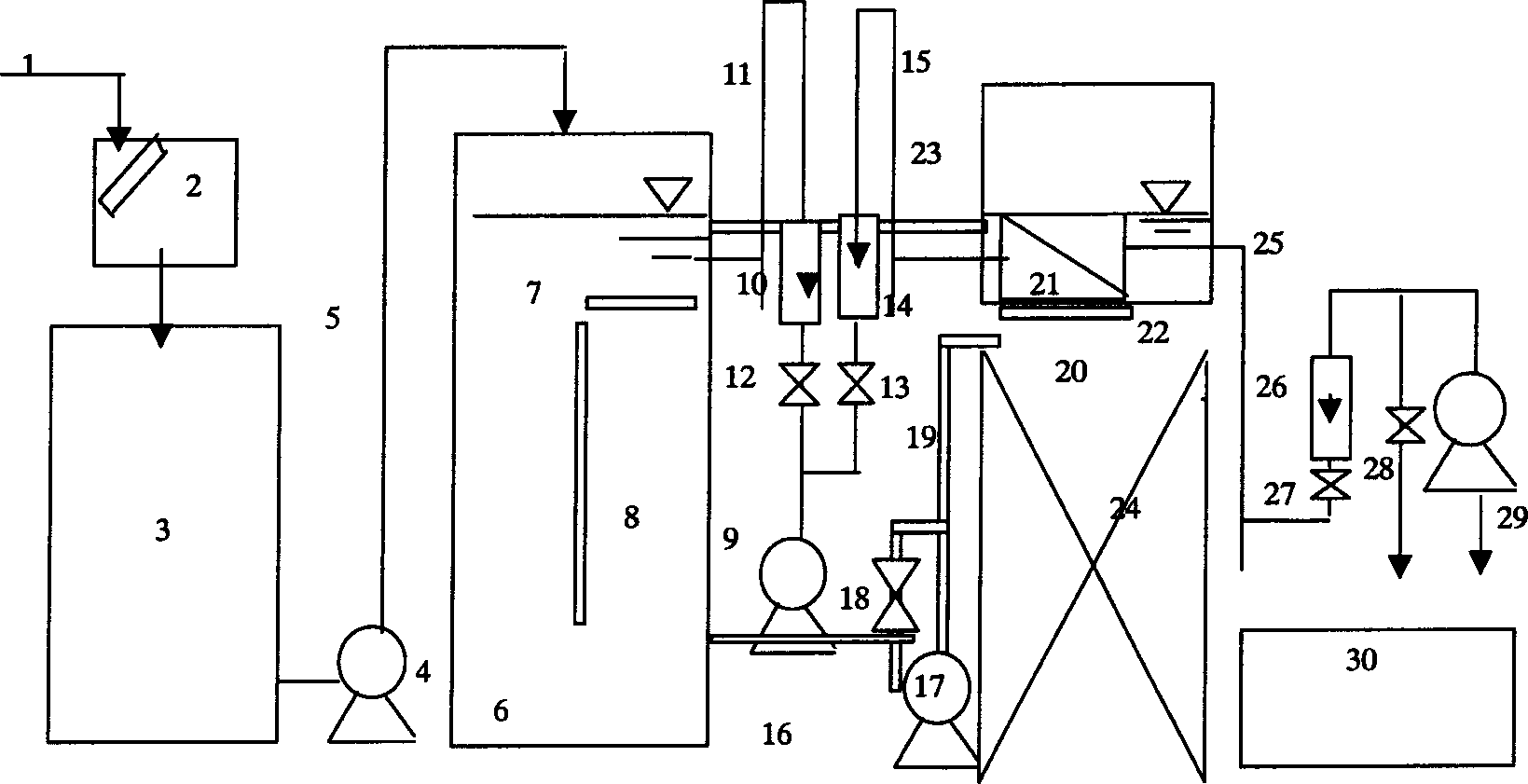

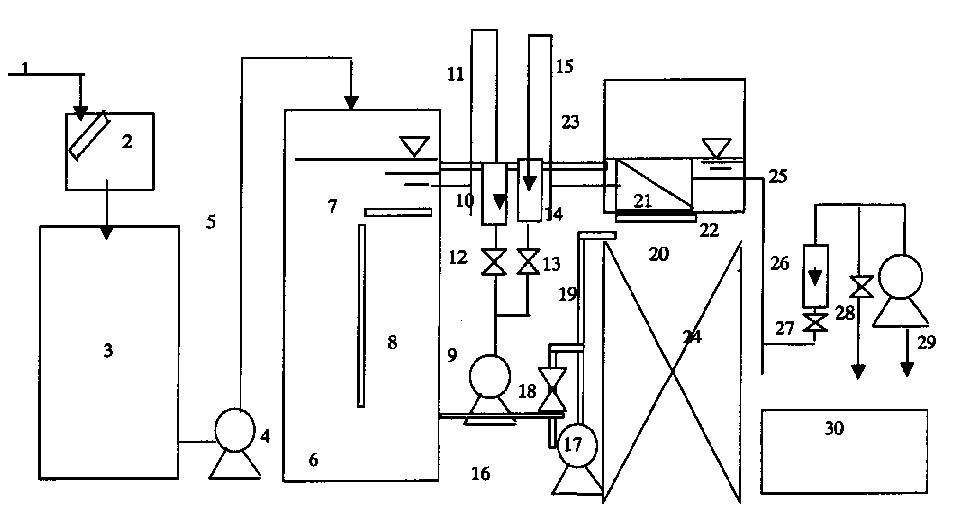

Method used

Image

Examples

Embodiment 1

[0013] A scale of 24m 3 / d The wastewater reuse project in residential areas adopts the known cross-flow split membrane bioreactor technology and the membrane bioreactor technology of the present invention for flushing the shallow water layer with aerated membranes.

[0014] Known cross-flow split-type membrane bioreactor: the membrane surface flow rate of the membrane separation unit is 3.6m / s, and the energy consumption per unit of water treatment is 3.0kW·h / m 3 .

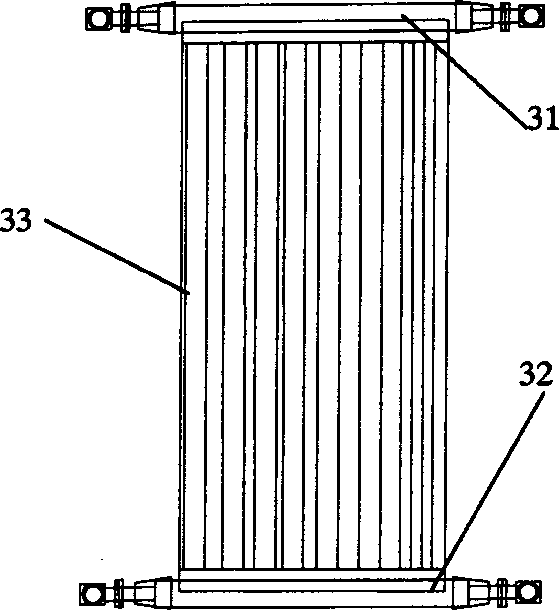

[0015] Adopting the split-type membrane bioreactor technical scheme of the present invention, that is, adopting the split-type membrane bioreactor technology in which the membrane is flushed by blowing air in the shallow water layer in the membrane filter tank. The water depth of the bioreactor is 3 meters, the length of the membrane module is 1 m, that is, the distance from the upper edge of the upper water collecting pipe 31 to the lower edge of the lower water collecting pipe 32 is 1 m, and the water depth of...

Embodiment 2

[0017] A scale of 24m 3 / d Preliminary analysis and comparison of operating energy consumption of the sewage reuse project in residential areas using the known submerged split-type membrane bioreactor technology and the split-type membrane bioreactor technology of the present invention.

[0018] Known submerged split-type membrane bioreactor: the water depth of the bioreactor is 3m, and the length of the membrane module is 1m, that is, the distance from the upper edge of the upper water collection pipe 31 to the lower edge of the lower water collection pipe 32 is 1m. The air-water ratio is 40:1, that is, the total blowing volume is 40m3 / h, treatment water volume 1m 3 / h, the blowing pressure is about 30kPa, the blowing efficiency is 0.44, and the energy consumption per unit of water treatment is 0.7kW·h / m 3 , water supply, circulation and aeration energy consumption 0.4kW h / m 3 , the energy consumption per unit of water treatment is 1.1kW·h / m 3 .

[0019] Adopting the sp...

Embodiment 3

[0021] A scale of 24m 3 / d Preliminary analysis and comparison of operating energy consumption of the sewage reuse project in residential areas using the known submerged split-type membrane bioreactor technology and the split-type membrane bioreactor technology of the present invention.

[0022] Known submerged split-type membrane bioreactor: the water depth of the bioreactor is 3m, and the length of the membrane module is 1m, that is, the distance from the upper edge of the upper water collection pipe 31 to the lower edge of the lower water collection pipe 32 is 1m. The air-water ratio is 40:1, that is, the total blowing volume is 40m 3 / h, treatment water volume 1m 3 / h, the blowing pressure is about 30kPa, the blowing efficiency is 0.44, and the energy consumption per unit of water treatment is 0.7kW·h / m 3 , water supply, circulation and aeration energy consumption 0.4kW h / m 3 , the energy consumption per unit of water treatment is 1.1kW·h / m 3 .

[0023] Adopting the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com