Device for obtaining slag flow-out signal in casting steel with ladle

A technology of pouring steel and molten slag, which is applied in the field of non-electricity detection, can solve the problems of slow temperature change speed and outflow speed, which affects the detection effect of the device, and only occurs at the end of steel pouring, so as to achieve high accuracy and increase anti-interference performance , good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

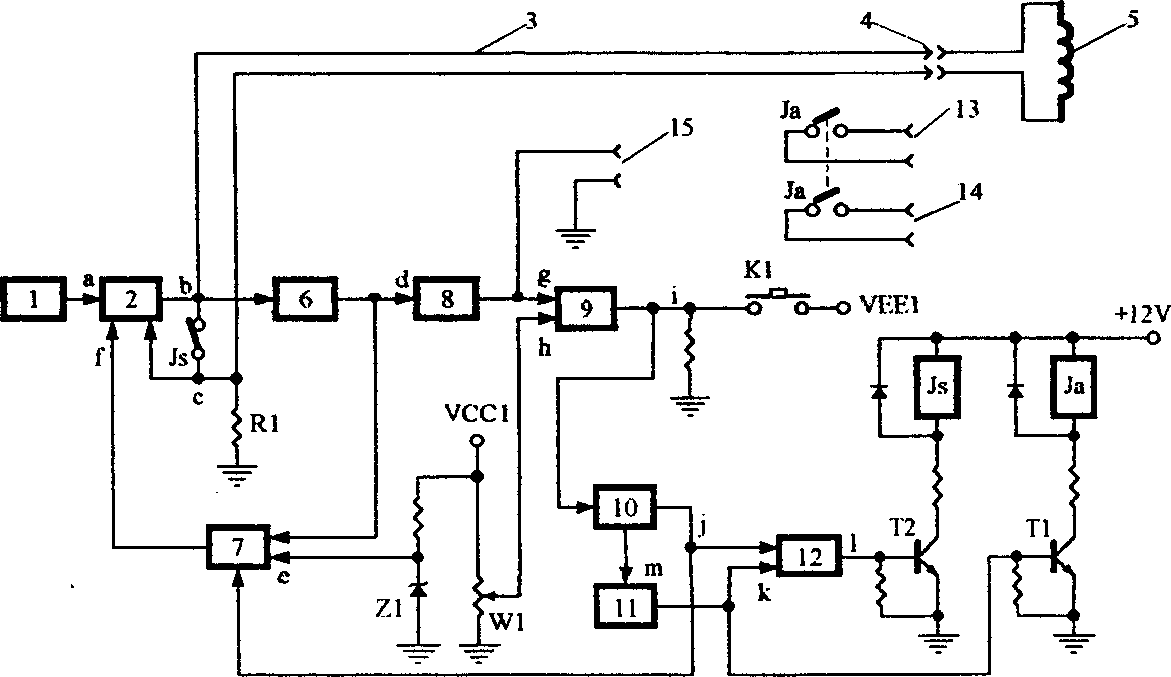

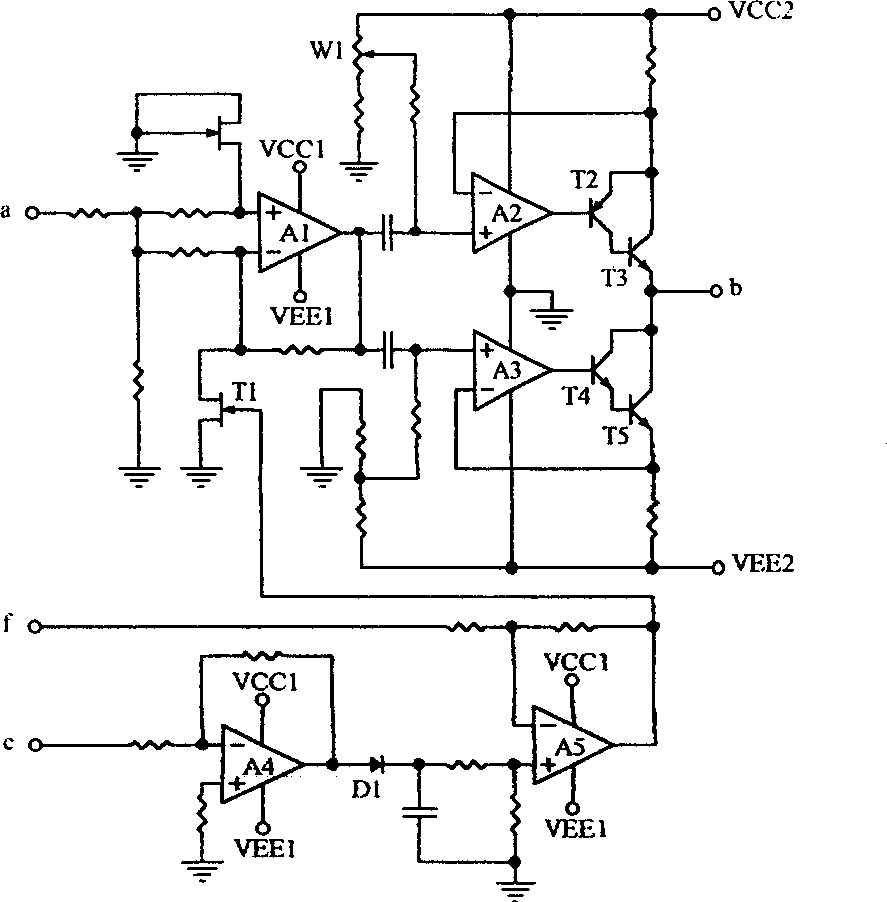

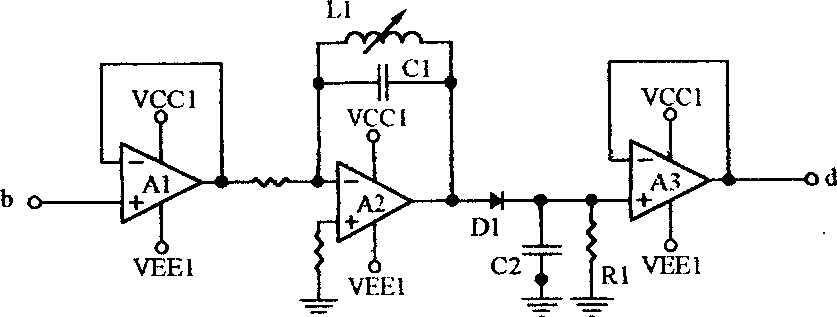

[0018] Structural block diagram of the present invention is as figure 1 As shown, it includes a sine wave oscillator 1, a transconductance amplifier circuit 2, a peak detector circuit 6, a numerically controlled resistor network voltage divider 7, a filter amplifier circuit 8, a voltage comparator 9, a bistable trigger 10, a monostable Trigger 11, RS trigger 12, relay; the output of sine wave oscillator 1 is connected to sensor 5 through transconductance amplifier 2, twin-core cable 3, high temperature connector 4, and the output of transconductance amplifier 2 is through peak detection circuit 6, The filter amplifier circuit 8 is connected to the voltage comparator 9, the other input terminal of the voltage comparator 9 is connected to the adjustable positive potential, the output terminal is connected to the negative potential and the bistable trigger 10 through the button, and the input of the digitally controlled resistor network voltage divider 7 Connect the output termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com