High-pressure waste TA converting process of preparing DMT

A high-pressure, high-tech technology, which is applied in the field of preparation technology for the conversion and reuse of terephthalic acid to dimethyl terephthalate, can solve the problems of the conversion process of polluted waste and low recovery rate, and achieve pollution-free, High recovery rate and the effect of increasing the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

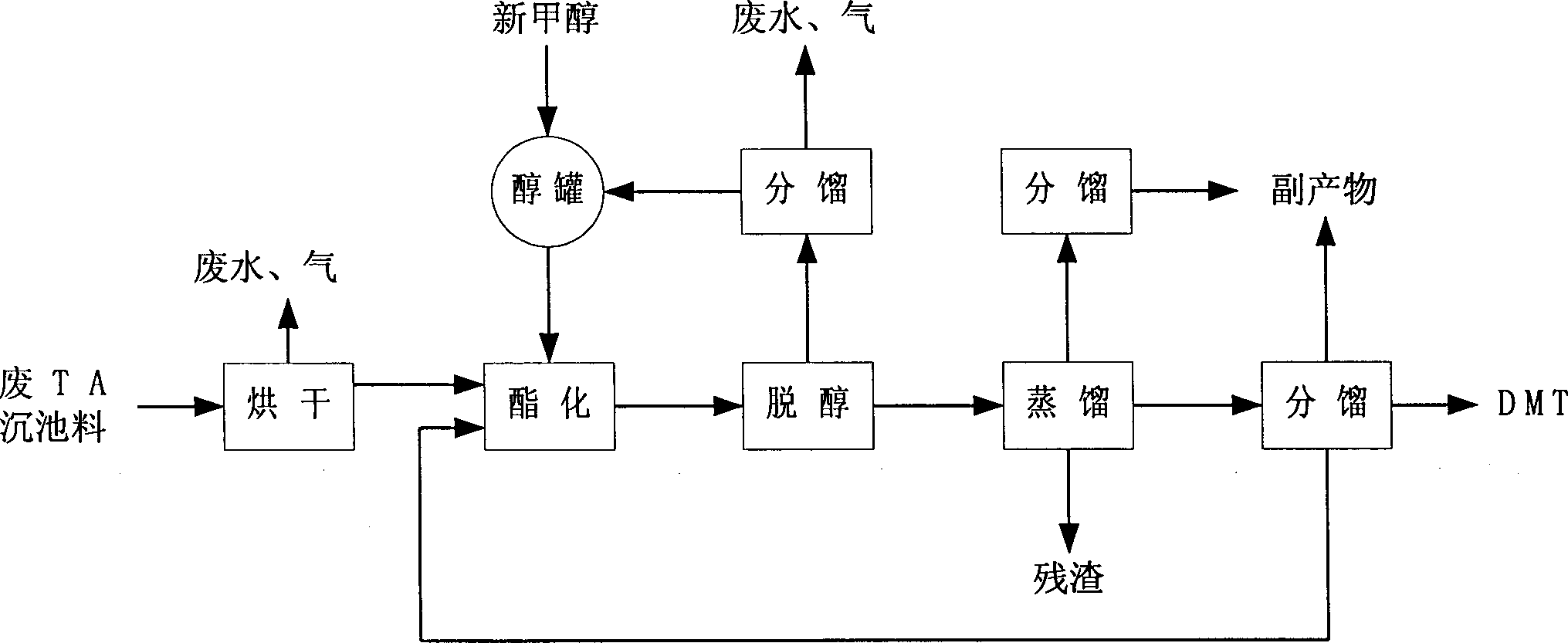

Image

Examples

Embodiment 1

[0013] After the waste TA material is dried at 160°C, it is put into an autoclave, and 3 times the weight of methanol is added, and the temperature is raised for esterification. The pressure was controlled at 2.5 MPa (gauge pressure), the temperature was controlled at 230° C., and the esterification time was 15 hours. After the esterification process is completed, the pressure is gradually reduced to normal pressure, the esterification water is discharged, and excess methanol is recovered. Then gradually reduce the pressure to 50mmHg (absolute pressure), distill and recover the low boilers of fractions below 180°C, and then collect the fractions within 180-200°C as crude DMT to obtain: recovery of methanol, low boilers, and crude DMT and residue. Recovery of methanol, low boilers, crude DMT and fractional distillation to obtain: recycled methanol, by-products and product DMT.

Embodiment 2

[0015] After drying the waste TA material at 170°C, put it into an autoclave, add 3 times the weight of methanol and about 8% weight of crude DMT, and heat up to esterify. The pressure was controlled at 3.5 MPa (gauge pressure), the temperature was controlled at 215° C., and the esterification time was 16 hours. After the esterification process is completed, the pressure is gradually reduced to normal pressure, the esterification water is discharged, and excess methanol is recovered. Then gradually reduce the pressure to 50mmHg (absolute pressure), distill and recover the low boilers of fractions below 180°C, and then collect the fractions within 180-200°C as crude DMT to obtain: recovery of methanol, low boilers, and crude DMT and residue. Recovery of methanol, low boilers, crude DMT and fractional distillation to obtain: recycled methanol, by-products and product DMT.

Embodiment 3

[0017] After drying the waste TA material at 180°C, put it into an autoclave, add 3 times the weight of methanol and about 10% by weight of crude DMT, and heat up for esterification. The pressure was controlled at 3 MPa (gauge pressure), the temperature was controlled at 230° C., and the esterification time was 15 hours. After the esterification process is completed, the pressure is gradually reduced to normal pressure, the esterification water is discharged, and excess methanol is recovered. Then gradually reduce the pressure to 50mmHg (absolute pressure), distill and recover the low boilers of fractions below 180°C, and then collect the fractions within 180-200°C as crude DMT to obtain: recovery of methanol, low boilers, and crude DMT and residue. Recovery of methanol, low boilers, crude DMT and fractional distillation to obtain: recycled methanol, by-products and product DMT. The preparation of DMT in a 0.5-liter autoclave is completed intermittently in two steps. For eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com