Internal combustion engine for driving propeller shaft

A technology for internal combustion engines and crankshafts, applied in the direction of motor-driven engines, engine components, sliding contact bearings, etc., can solve the problems of no thrust bearing bush, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

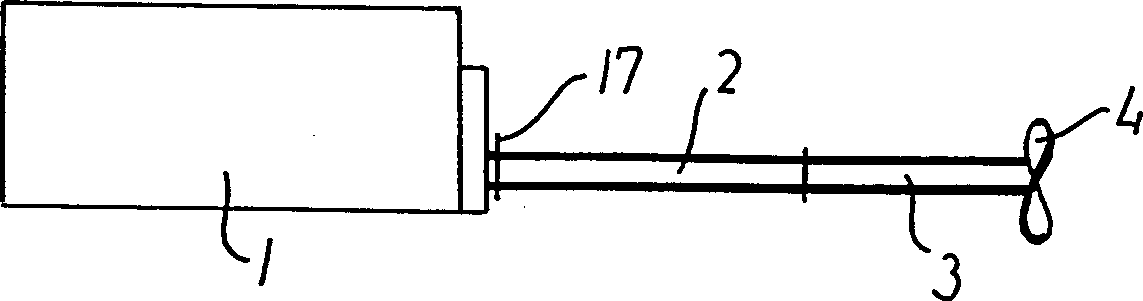

[0024] figure 1 There is illustrated an internal combustion engine 1 connected via an intermediate shaft 2 to a propeller shaft 3 with a propeller 4 . The internal combustion engine may be a four-stroke engine or a two-stroke engine, such as the applicant's ME or MC two-stroke crosshead engine, which are known to those skilled in the art. The engine may have a bore of 30 to 120 cm, the number of cylinders may be 5 to 20, and for a crosshead engine, the rotational speed may be 60 to 300 rpm. The output power of the engine can be, for example, 3000 to 130000 kW. The engine preferably has a relatively large output power, such as at least 30,000 kW, with at least 8 cylinders and a bore of at least 70 cm.

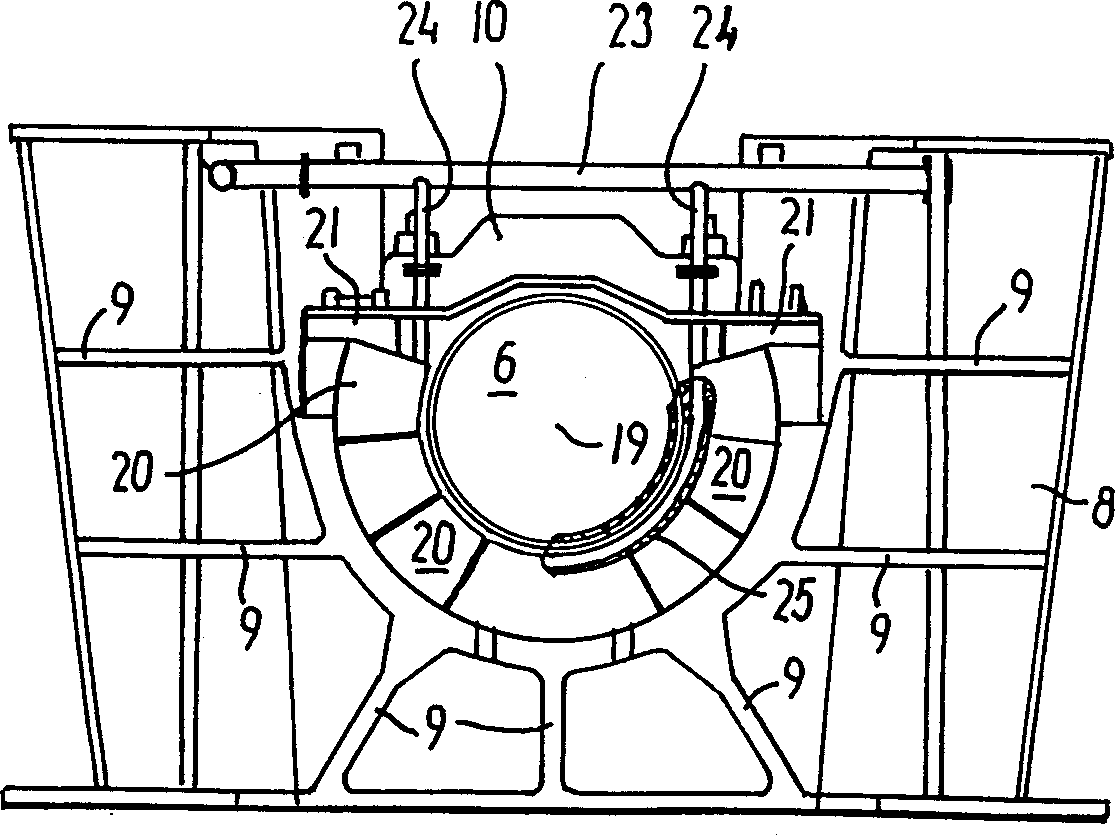

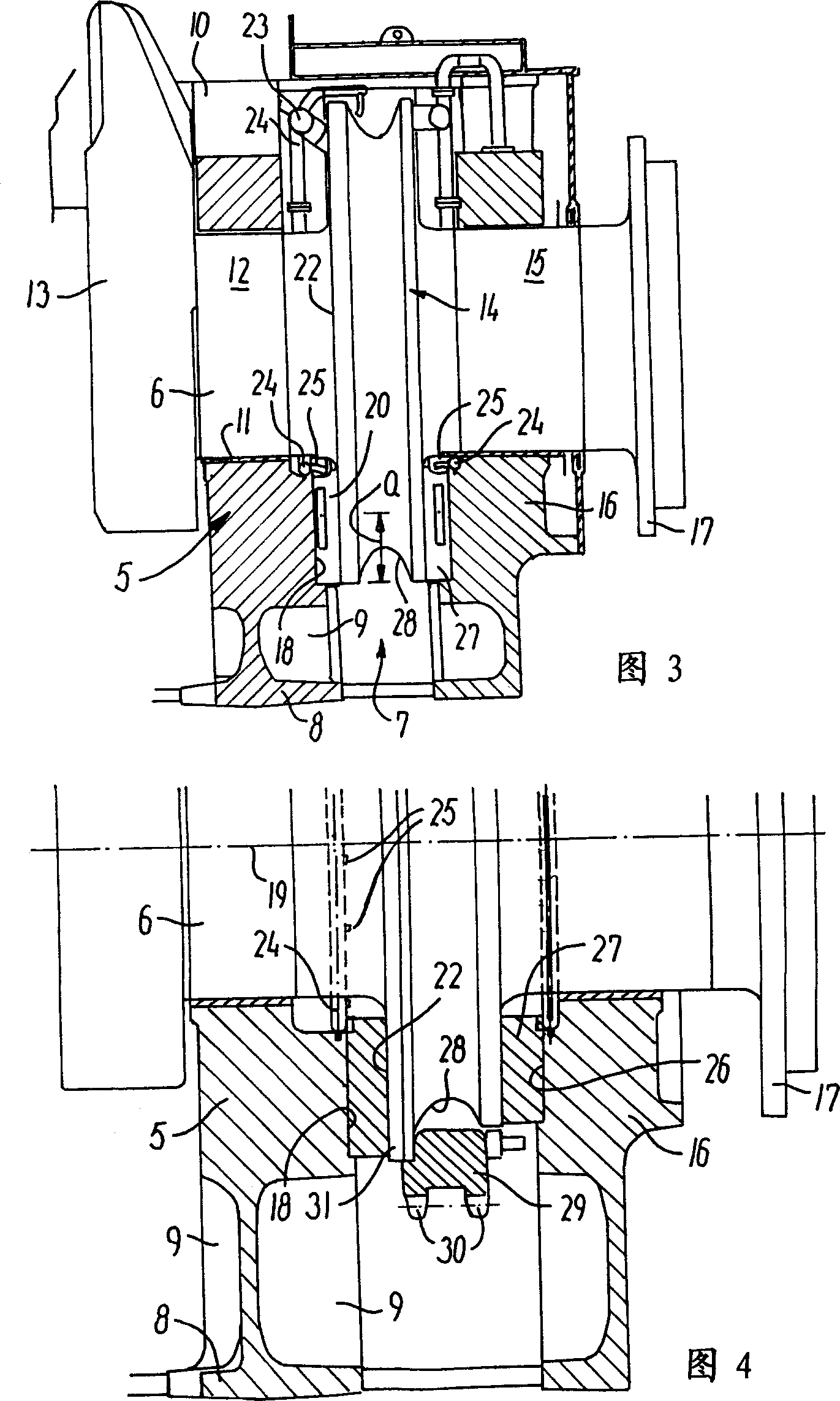

[0025] In the rearmost main bearing 5 of the crankshaft 6, the internal combustion engine 1 has a figure 2 The rear view of the thrust bearing 7, the longitudinal section of the thrust bearing is shown in Figure 3. The fixed bearing seat of the main bearing 5 is cast in one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com