High-strength high-impact toughness bearing steel and its heat treatment process

A high-impact, high-strength technology, applied in the field of steel materials and their processing technology, can solve problems such as long production cycle, low production efficiency, and complexity, and achieve the effect of simple method, improving strength and impact resistance, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to the high-strength, high-impact-toughness bearing steel of the present invention, the chemical composition of the steel type is, % by weight: C: 0.6-1.0, Si: 0.7-1.8, Mn: 0.3-0.85, Cr: 0.1-1.9, Mo: 0.15-0.8, V: 0.15-0.6, W: 0.1-0.6, rare earth: 0.01-0.20, S: ≤0.025, P≤0.025, and the rest are Fe except for unavoidable impurities.

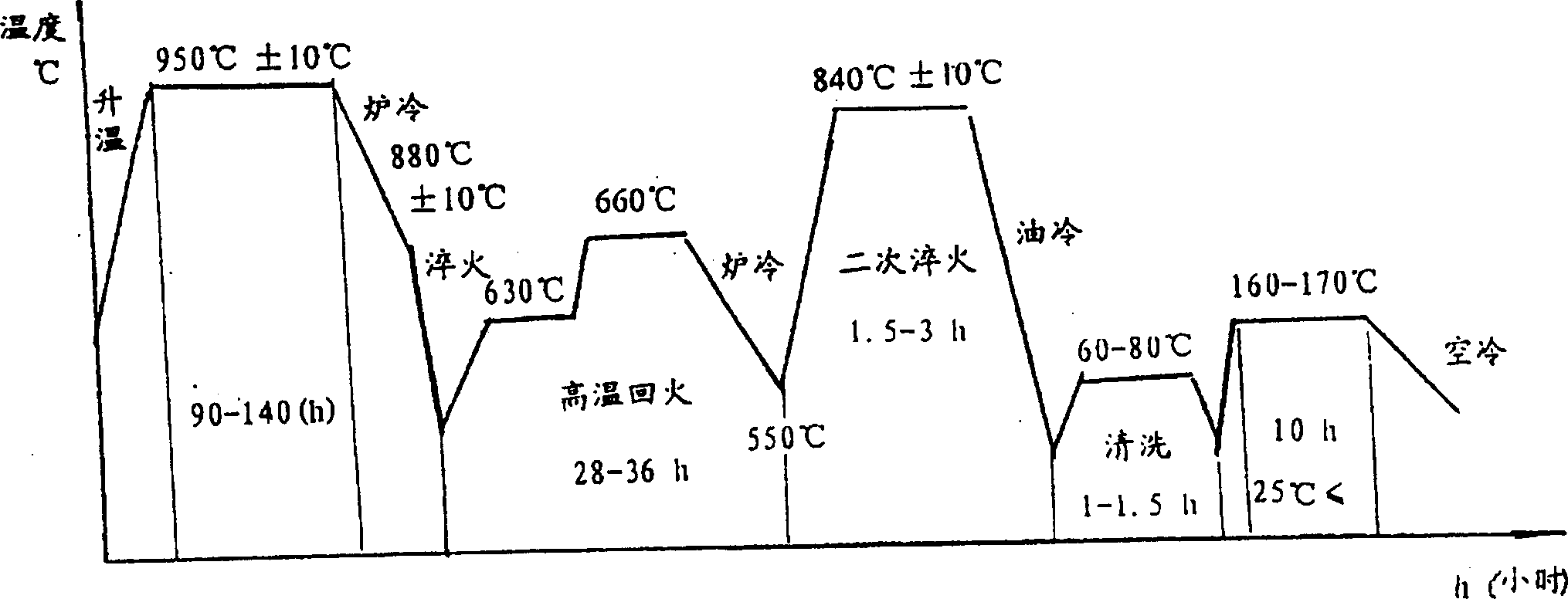

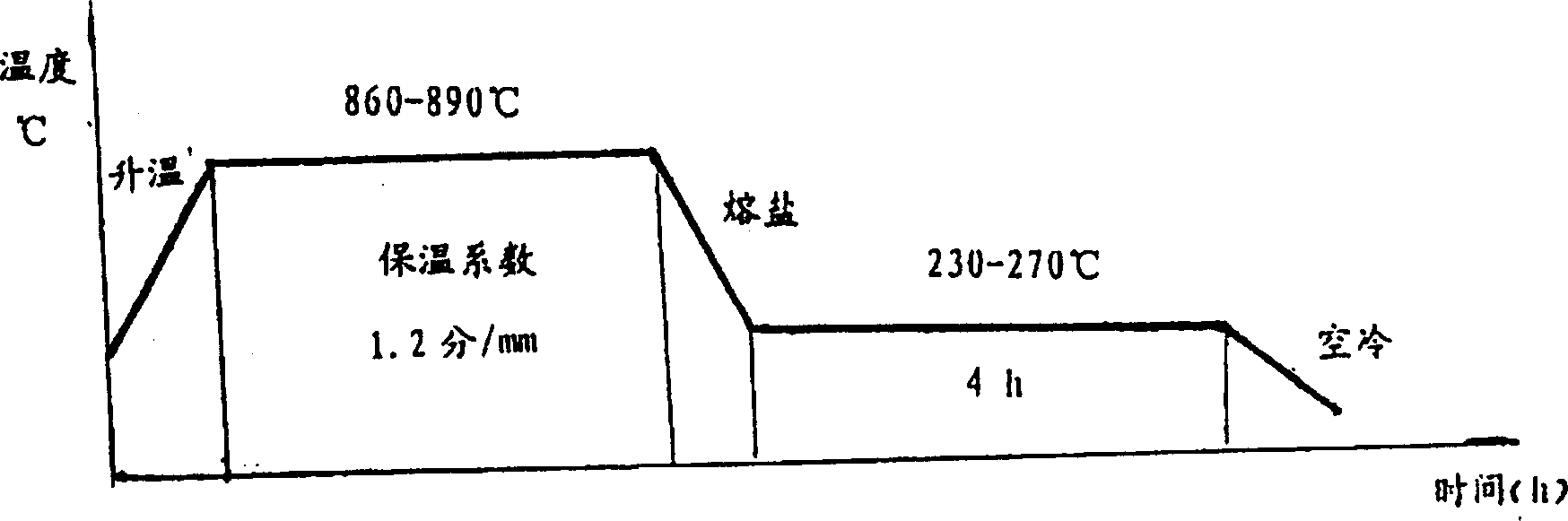

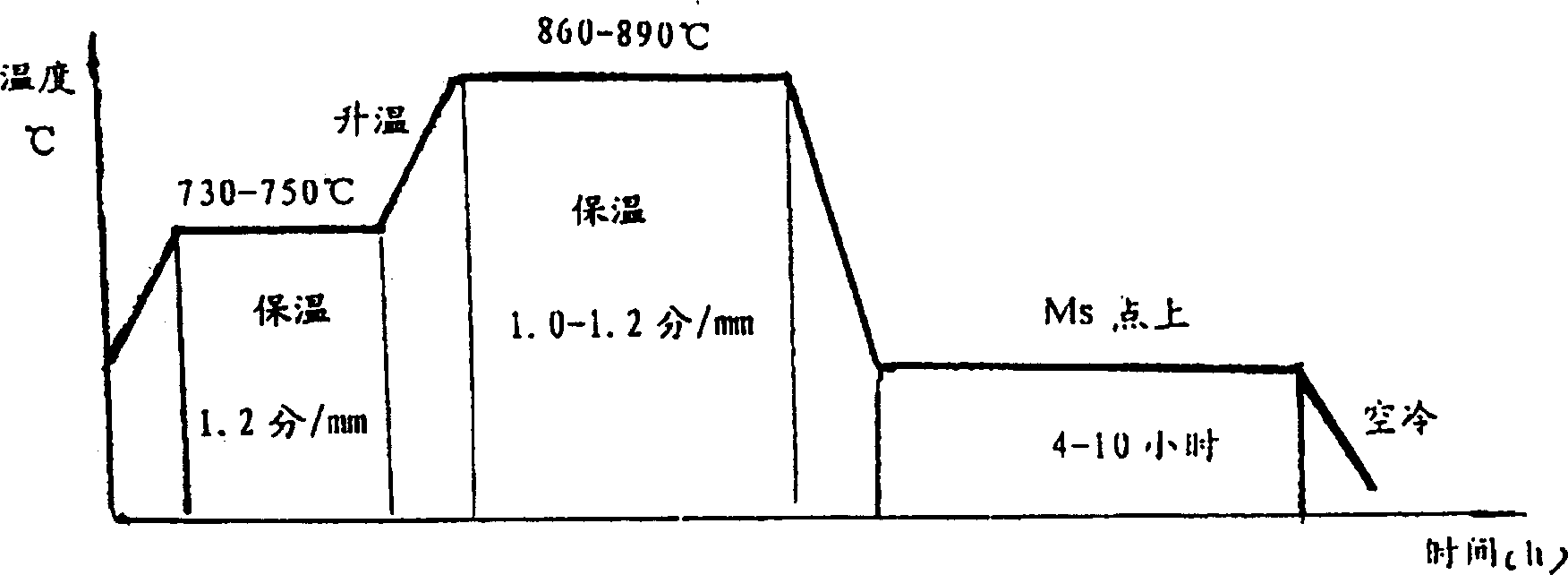

[0029] The heat treatment process of the present invention is as follows: the effective wall thickness of the above-mentioned component bearing ring is greater than 45mm, and the bearing of the size segment above 45mm is processed by using an electric frequency 1000-8000Hz high-frequency quenching and tempering treatment process. -890°C±10°C, the heat preservation time is calculated according to the heat preservation coefficient of 1.2 minutes / mm. After quenching, the high temperature surface quenching process is carried out. First, the bearing parts before turning are subjected to quenching and tempering treatment to make zero to s...

Embodiment 2

[0032] According to another embodiment of the present invention, said high-strength, high-impact-toughness bearing steel has the following composition, % by weight: C: 0.6-0.65, Si: 1.0-1.2, Mn: 0.4-0.6, Cr: 0.2-0.4 , Mo: 0.5-0.6, V: 0.18-0.25, W: 0.1-0.2, rare earth: 0.04-0.05, S: ≤ 0.025, P ≤ 0.025, and the rest are Fe except unavoidable impurities. Its heat treatment process is the same as above.

Embodiment 3

[0034] According to another embodiment of the present invention, said high-strength, high-impact-toughness bearing steel has the following composition, % by weight: C: 0.65-0.75, Si: 1.2-1.3, Mn: 0.6-0.7, Cr: 0.25-0.35 , Mo: 0.3-0.5, V: 0.2-0.4, W: 0.31-0.45, rare earth: 0.01-0.03, S: ≤ 0.025, P ≤ 0.025, and the rest are Fe except for unavoidable impurities. Its heat treatment process is the same as above. Table 1 is a comparative table of mechanical properties of three embodiments of the present invention and carburized steel.

[0035] Table 1 Note: 1. After quenching, the HRC of the new material is greater than that of the lower bainite, which improves the wear resistance.

[0036] 2. The impact toughness of the new material is higher than that of the current bearing steel, which is suitable for bearing manufacturing under heavy load and heavy impact conditions.

[0037] 3. New material radial load with carburizing steel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com