Process for separating oil, water and solid from oil-contained float slegs

A technology of solid matter and scum, which is applied in the field of environmental engineering, can solve the problems of high cost of chemicals and large investment in equipment, and achieve good economic value and the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

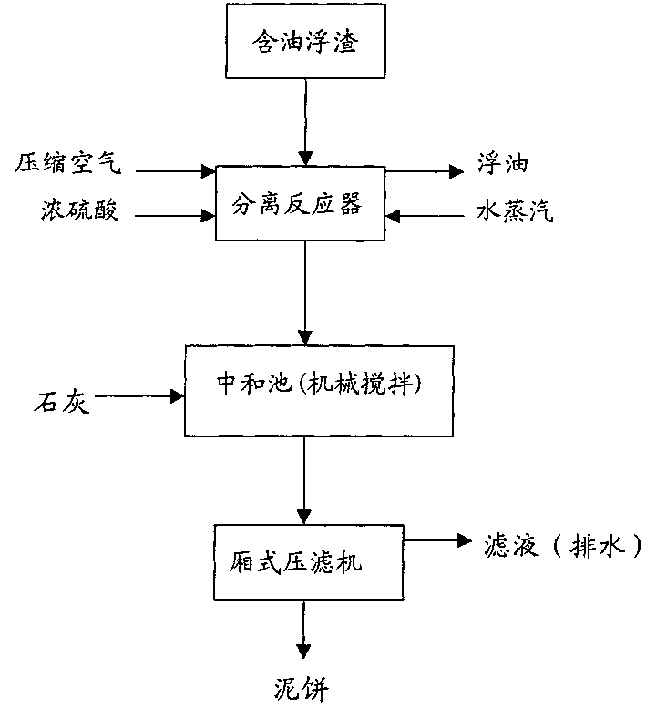

[0018] Use a thick slurry pump to lift the oily scum into the separation reactor, turn on the compressed air for stirring, add sulfuric acid to acidify, adjust the pH to between 2.0 and 3.0, stop the air stirring; turn on the steam for heating, when the medium temperature rises After reaching 75-85°C and keeping the temperature constant for 1 hour, stop heating. After standing and separating for 4 hours, drain the aqueous solution below the oil layer into the neutralization tank, and then add lime to adjust the pH to between 6.5 and 7.5. Using a thick slurry pump to lift the mixed liquid to a chamber filter press for filtration, solid-liquid separation is achieved.

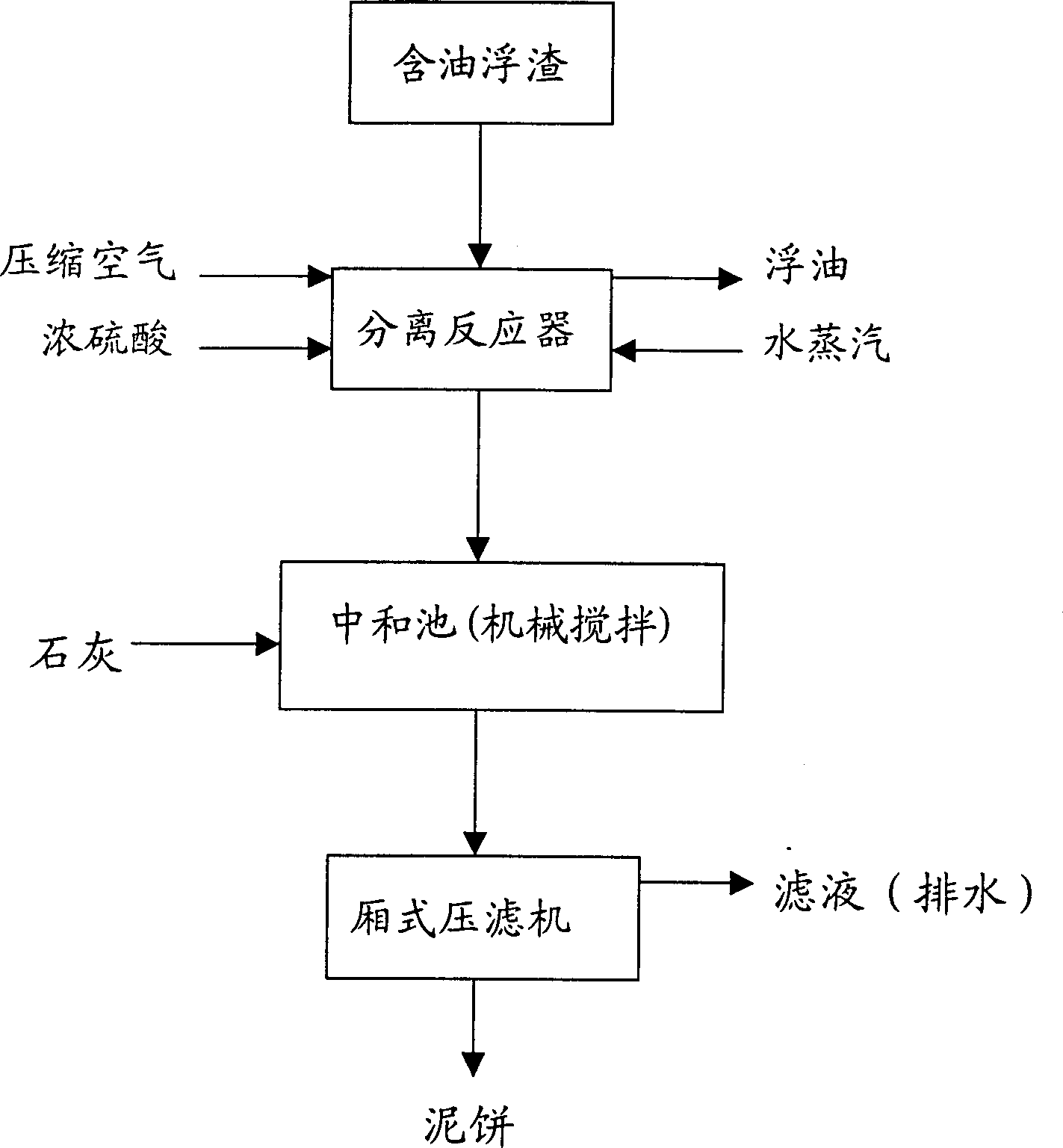

[0019] The process flow of the batch processing system of the present invention is as follows figure 1 Shown.

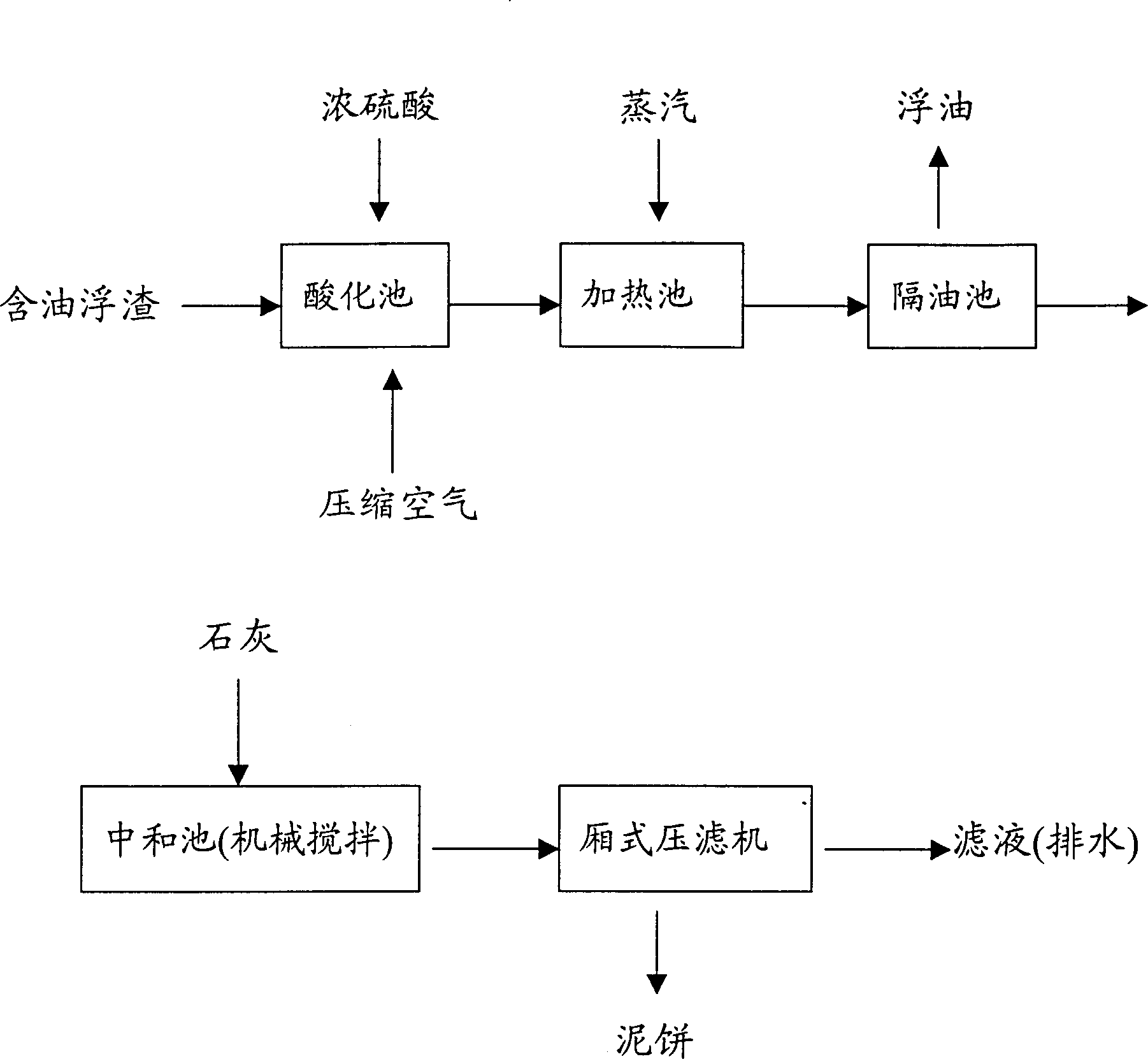

[0020] For companies with a large amount of scum, continuous flow treatment can also be used when using this technology. figure 2 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com