Compact high-voltage electric light-bulb

An incandescent lamp, high-voltage technology, applied in the direction of incandescent lamps, incandescent lamp parts, shells/tube shells of illuminants, etc., can solve problems such as poor lighting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

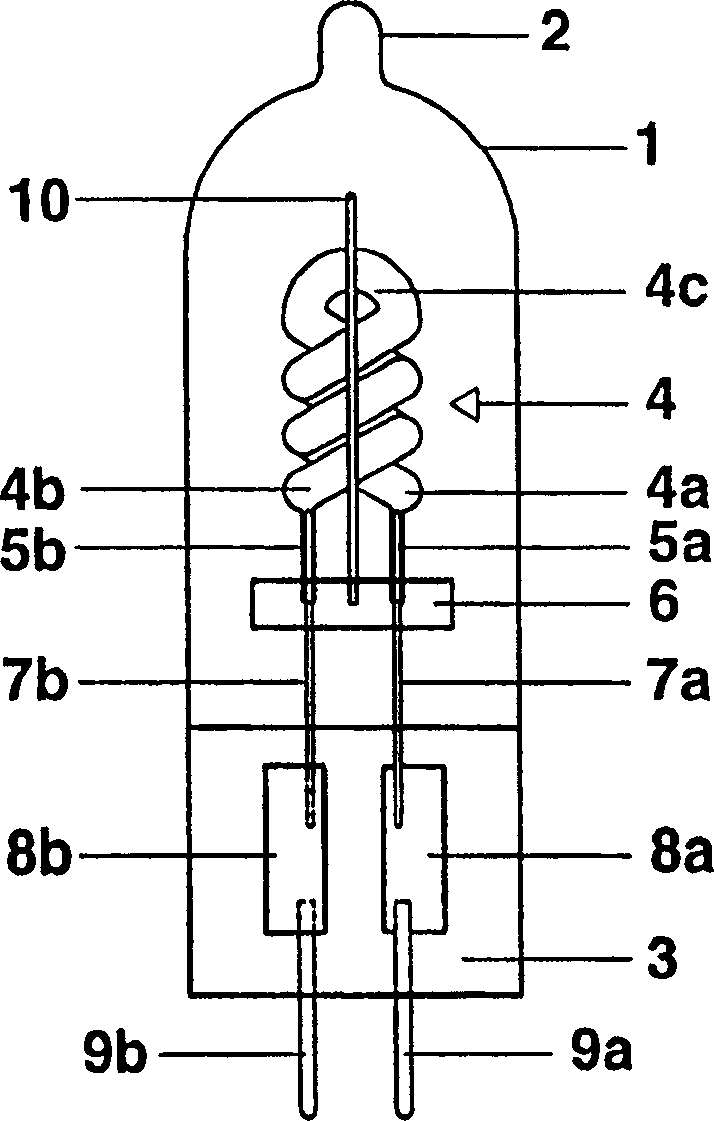

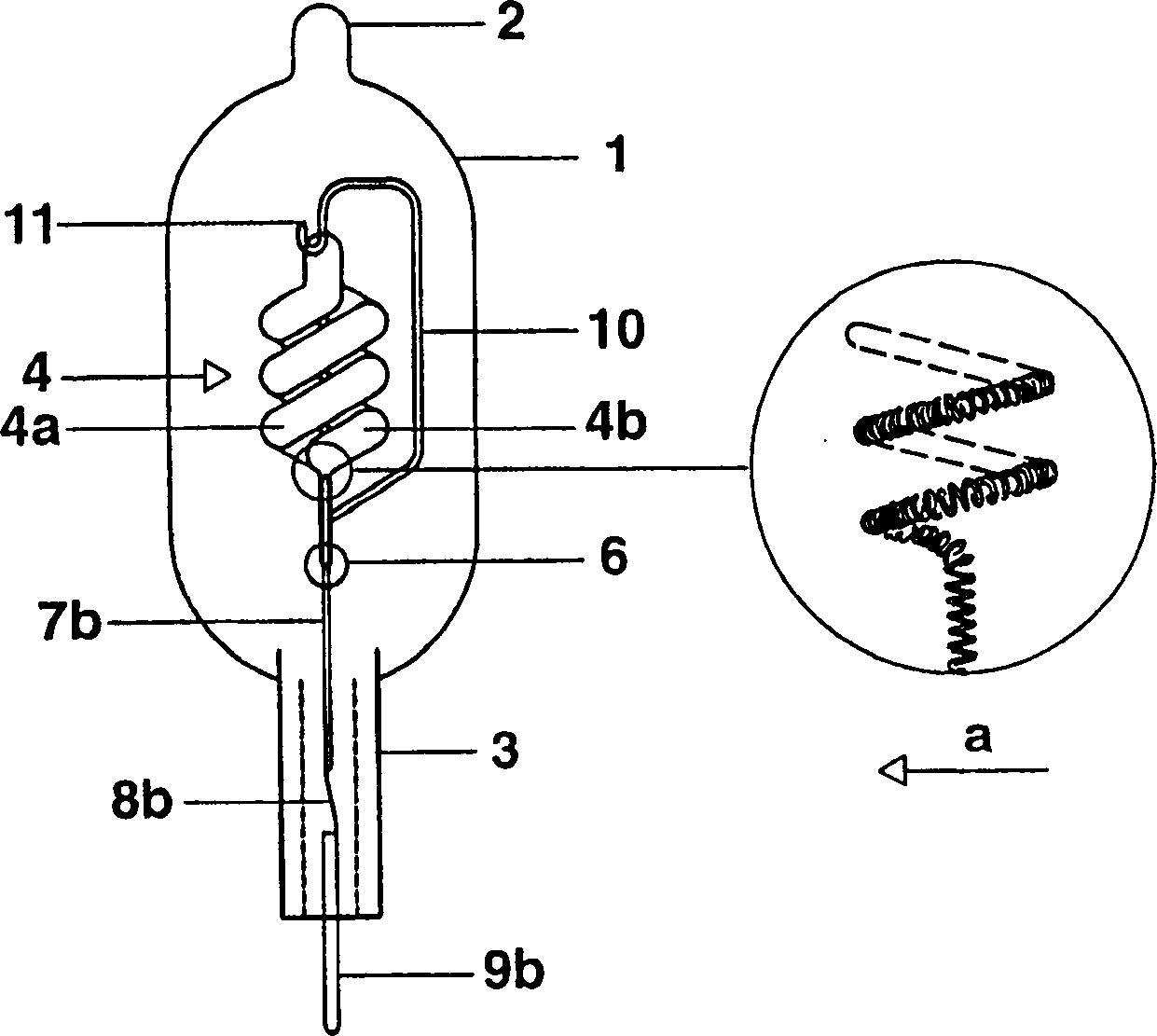

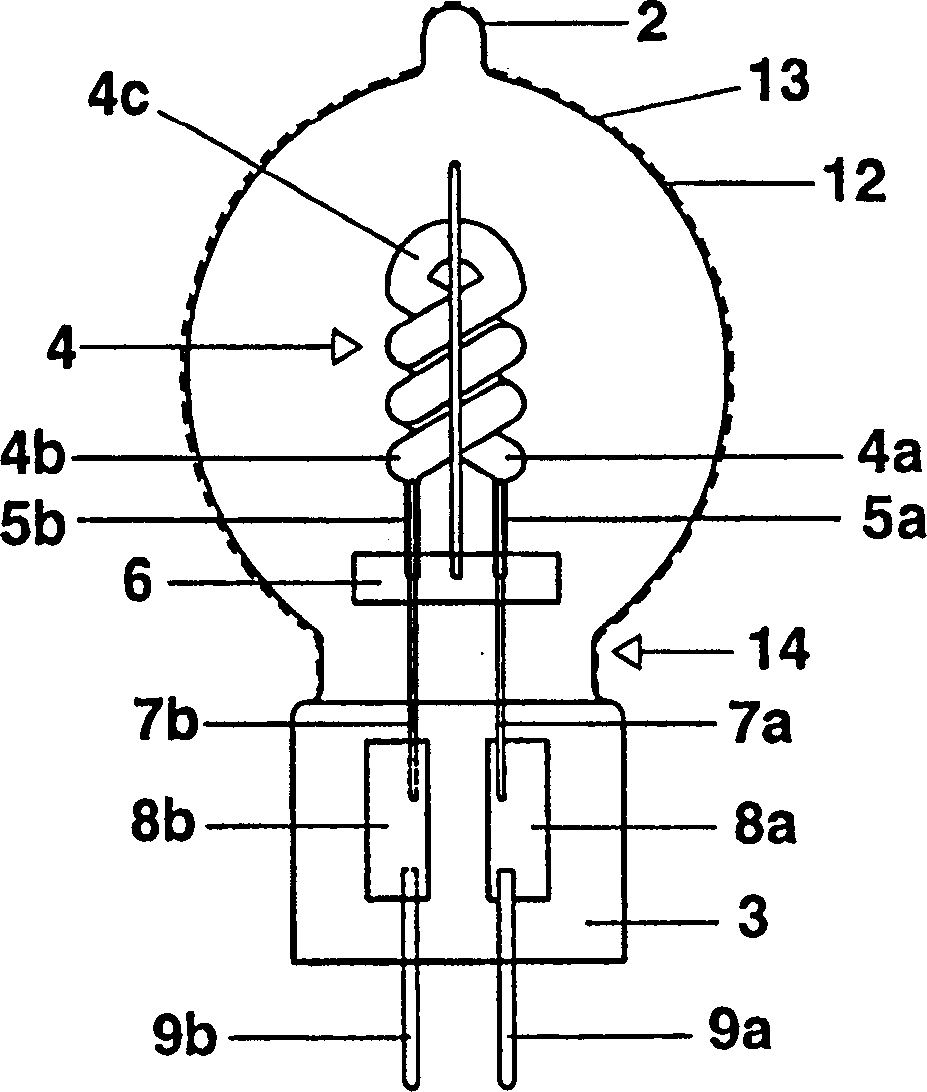

[0028] Figure 1a with 1b A schematic side view and a view rotated by 90° of the high-voltage halogen incandescent lamp extruded at one end of the present invention for a 230 volt supply voltage are respectively shown. Electric power consumption and light efficiency are 1000 watts and 25 lumens / watt (1m / W) respectively.

[0029] The lamp has a bulb 1 made of quartz glass. One end of the bulb is made into a dome with a sealed exhaust head 2; and on the other end, the bulb 1 is welded by an extrusion seal 3. Like a general halogen incandescent lamp, the bulb 1 is filled with a well-known halogen. The filling components are, for example, xenon and nitrogen and a few percent of halogen, such as dibromide (DBM). The inflation pressure is about 3 bar.

[0030] In the bulb 1, an integral luminous body 4 is arranged axially. Such as Figure 1b It can be clearly seen from the magnifying glass that the luminous body is composed of a well-known double helix tungsten filament 4a-4c, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com