Molecular beam source apparatus for film deposition and method for depositing film by molecular beam

A technology of molecular beam deposition and thin film deposition, applied in chemical instruments and methods, ion implantation plating, crystal growth, etc., can solve problems such as material utilization rate decline, thin film defects, uneven temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below with reference to the drawings.

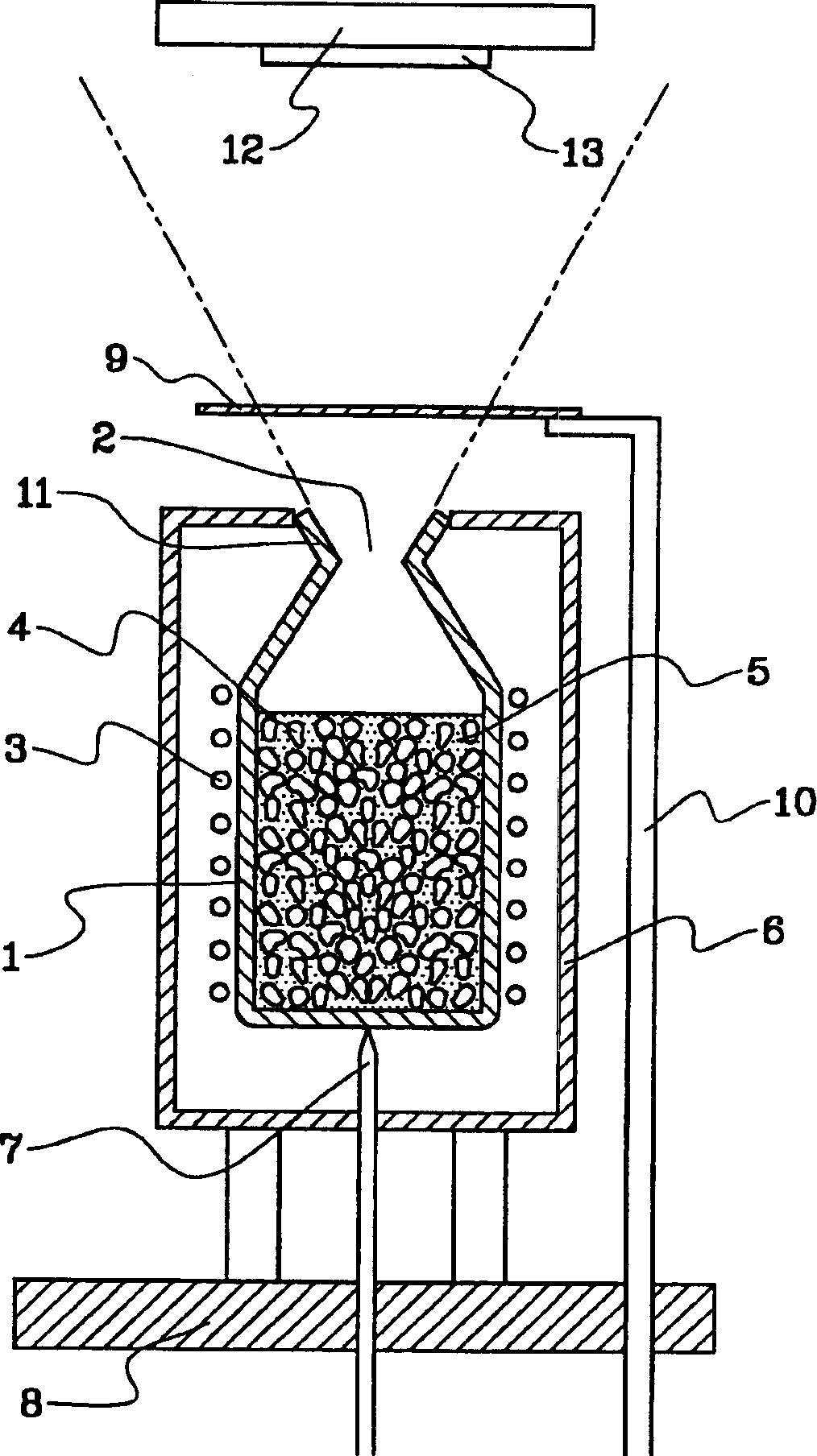

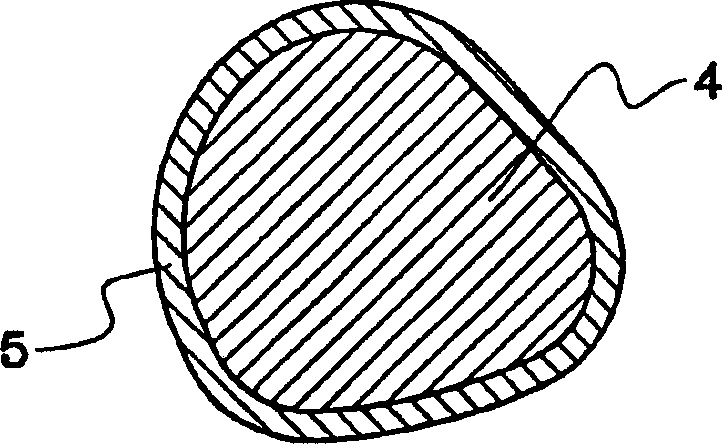

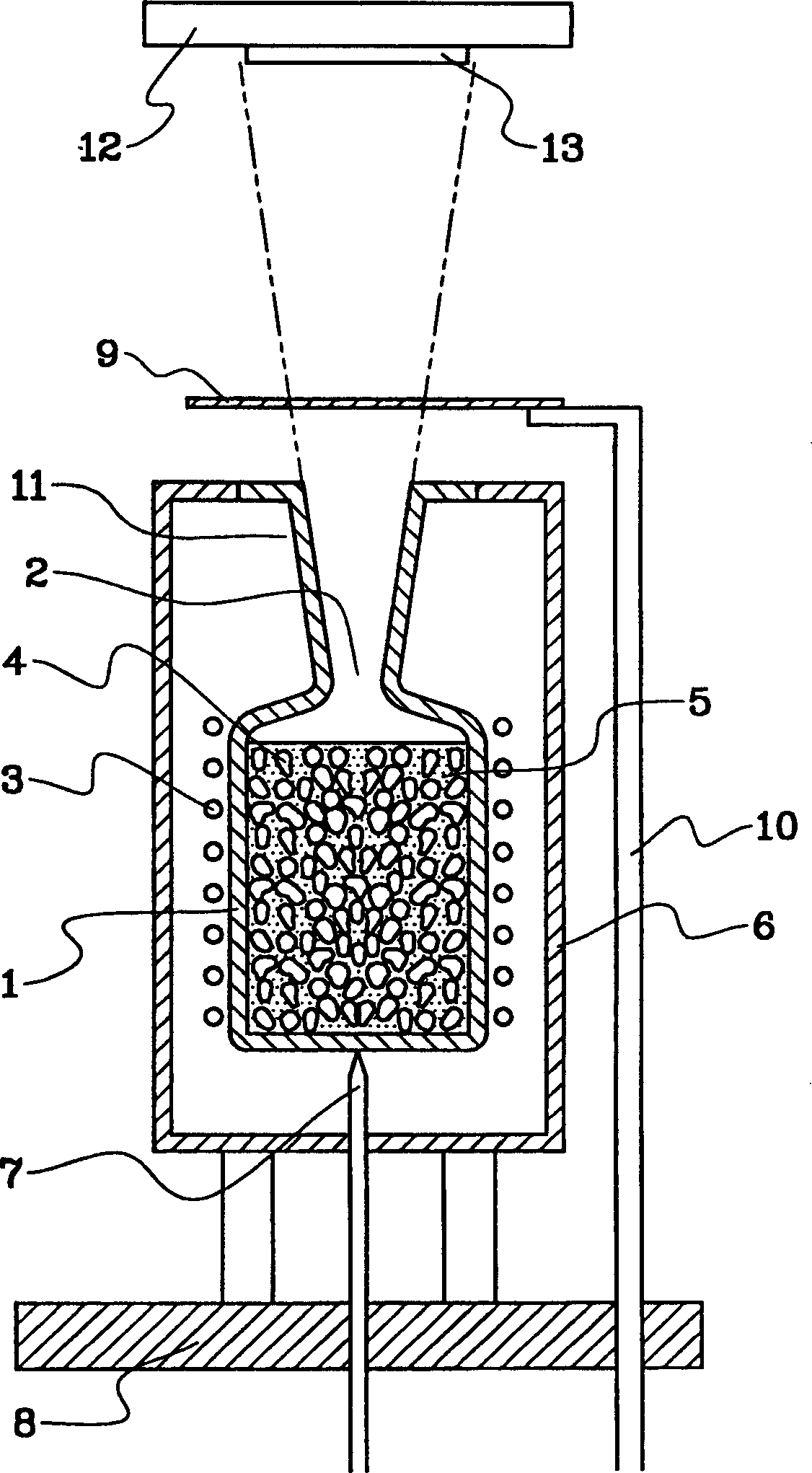

[0018] figure 1 A molecular beam source device for thin film deposition according to one embodiment of the present invention is schematically shown. Such as figure 1 As shown, a crucible 1 having a steam discharge port is provided at the upper end, and a heater 3 for heating an evaporation material 5 inside the crucible 1 is provided around the crucible 1 . The crucible 1 is made of a thermally and chemically stable material, for example PBN as described above. The portion of the vapor discharge port 2 of the crucible 1 shown in the figure has a tapered shape, and a tapered trumpet-shaped intake portion 11 is formed on the upper end side thereof. The body part below the steam outlet 2 of the crucible 1 containing the heat transfer medium 4 and the evaporation material 5 described later is cylindrical.

[0019] A reflector 6 that reflects the heat of the heater 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com