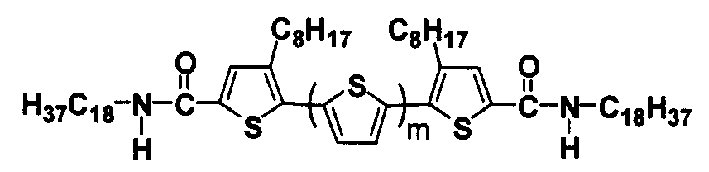

Oligothiophene derivative, its preparation method and application

A technology of oligothiophene and derivatives, applied in chemical instruments and methods, color-changing fluorescent materials, organic chemistry, etc., can solve problems such as difficult encapsulation, and achieve the effect of overcoming difficult encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] preparation

[0020] The first step is at -78℃, N 2 Under protection, the THF solution of DOc3T was added into the THF solution of LDA with a syringe, at this time, the solution turned red, and the reaction was stirred for 1 hour;

[0021] In the second step, dry ice (CO 2 ), at this time, the solution turns yellow, and at -78°C, N 2 Under protection, continue to react for 5 hours, then warm up to room temperature, continue to react for 3 hours;

[0022] In the third step, dilute hydrochloric acid was added to the reaction solution, solid matter appeared, and the reaction was continued for 8 hours, THF and water were removed by filtration, washed with water, and dried to obtain a yellow powdery product;

[0023] In the fourth step, the product is added to thionyl chloride (SOCl 2 ) in 1,2-dichloroethane solution until completely dissolved, reflux reaction for 5 hours, and remove the solvent;

[0024] The fifth step is to mix the product with stearylamine at 0°C und...

Embodiment 2

[0031] preparation

[0032] The first step is at -78℃, N 2 Under the protection of expansion, add the THF solution of DOc4T into the THF solution of LDA with a syringe. At this time, the solution turns red, and the reaction is stirred for 3 hours;

[0033] In the second step, dry ice (CO 2 ), at this time, the solution turns yellow, and at -78°C, N 2 Under protection, continue to react for 3 hours, then gradually warming up to room temperature, continue to react for 5 hours;

[0034] The third step is to add dilute hydrochloric acid to the reaction solution, solid matter appears, continue to react for 5 hours, remove THF and water by filtration, wash with water several times, and dry to obtain a yellow powder product;

[0035] In the fourth step, the product is added to thionyl chloride (SOCl 2 ) in 1,2-dichloroethane solution until completely dissolved, reflux for 8 hours, and remove the solvent;

[0036] The fifth step is to mix the product with stearylamine at 0°C unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com