Polythiophene derivative aqueous dispersion and preparation method thereof

A technology of polythiophene derivatives, applied in the field of polythiophene derivative aqueous dispersions and their preparation, can solve the problems of limiting the application of polythiophene derivative aqueous dispersions, low conductivity, poor stability, etc., and achieve excellent Water dispersibility, avoid peroxidation problem, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Specifically, the present invention provides a method for preparing an aqueous dispersion of polythiophene derivatives, comprising the following steps:

[0037] Step 1, mixing 3,4-dialkoxythiophene, polyanion, oxidizing agent, solubilizer and aqueous solvent for reaction;

[0038] Step 2, subjecting the solution obtained after the reaction to anion exchange and / or cation exchange treatment to obtain an aqueous dispersion of polythiophene derivatives;

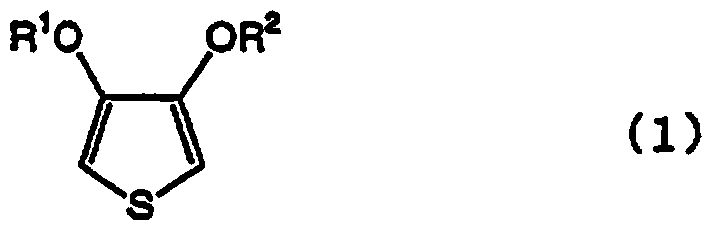

[0039] Wherein, the structural formula of the 3,4-dialkoxythiophene is shown in the following formula (1):

[0040]

[0041] (1) In the formula, R 1 , R 2 are independent of each other and are hydrogen or C 1-4 Alkyl groups, or together form C 1-4 The alkylene group can be optionally substituted.

[0042] Wherein, the molar ratio of the 3,4-dialkoxythiophene, polyanion and oxidant is: 3,4-dialkoxythiophene:polyanion:oxidant=1:2~50:1.5~3, the The mass ratio of 3,4-dialkoxythiophene to solubilizer is: 3,4-dialkoxythi...

Embodiment 1

[0063] Solubilizer: polyoxyethylene stearate

[0064] Oxidant: 35wt% sodium persulfate aqueous solution + 1wt% ferric sulfate aqueous solution

[0065] Aqueous solvent: deionized water

[0066] 100g polystyrene sulfonic acid, 9.1g polyoxyethylene stearate (HLB value 16.5~17.5), 50g of 35wt% sodium persulfate aqueous solution, 14.4g of 1wt% iron sulfate aqueous solution were added to 2000g deionized water in sequence , stirred for 30 minutes, and then 9.1 g of 3,4-dialkoxythiophene was added to the above aqueous solution, and stirred for 24 h. After the reaction, add 200g of cationic resin and 200g of anionic resin to the reaction system and stir for 12h, filter off the resin to obtain poly(3,4-dialkoxythiophene) polyanion dispersion. After testing, the dispersion contains 0.4wt% of poly(3,4-dialkoxythiophene), 1.3wt% of polystyrenesulfonic acid, 0.4wt% of polyoxyethylene stearate, and a solid content of 2.1wt%. , viscosity is 2000cps, particle size d 50 It is 105nm, and th...

Embodiment 2

[0068] Solubilizer: castor oil polyoxyethylene ether

[0069] Oxidant: 35wt% sodium persulfate aqueous solution + 1wt% ferric sulfate aqueous solution

[0070] Aqueous solvent: deionized water

[0071] 100g polystyrene sulfonic acid, 10.9g castor oil polyoxyethylene ether (HLB value 15.5~16.5), 50g 35wt% sodium persulfate aqueous solution, 14.4g 1wt% ferric sulfate aqueous solution were added to 2000g deionized water successively, Stir for 30 minutes, then add 9.1 g of 3,4-dialkoxythiophene into the above aqueous solution, and stir for 24 h. After the reaction, add 200 g of cationic resin and 200 g of anionic resin to the reaction system and stir for 12 hours, filter off the resin, and obtain poly(3,4-dialkoxythiophene) polyanionic dispersion. After testing, the dispersion contains 0.4wt% poly(3,4-dialkoxythiophene), 1.4wt% polystyrenesulfonic acid, 0.5wt% castor oil polyoxyethylene ether, and a solid content of 2.3wt%. The viscosity is 2300cps, the particle size is d 50 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com