Rocking type slag-cooling machine

A slag cooler and swing type technology, which is used in the field of special devices for continuous transmission of high-temperature solid powder or mixed high-temperature materials. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

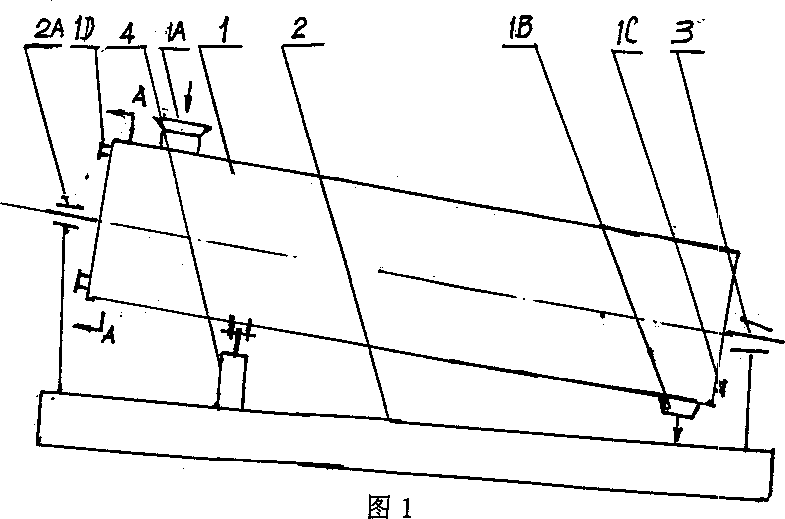

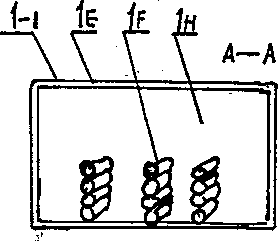

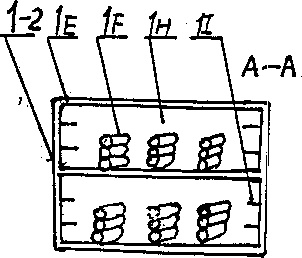

[0021] Due to the swing driving mode, the box body 1 produces a radial inclination angle during the driving process. This inclination angle can generally be controlled between 10° and 30°, so that the box body will generate an axial angle with respect to the horizontal plane. The synthetic inclination angle of the radial angle, so that during the reciprocating rocking process, the high-temperature material in the box will change direction and move according to the azimuth angle given by the heat-absorbing guide piece 1G or the exhaust pipe 1F set in the box, and at the same time The tumbling and moving of the high-temperature material due to the inclination of the inner cavity of the box forms the mixing and exchange position of the high-temperature material in the uniform motion and tumbling, so that the heat-absorbing area and contact time are artificially controlled and enhanced, and the laminar flow and heat conduction resistance are overcome. Hysteresis and other problems ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com