Strong mastic for wall

A putty and coating technology, applied in the field of strong putty, can solve the problems of high flatness, large shrinkage, cracking and other problems of the base surface, and achieve the effects of stable chemical properties, strong self-cleaning function and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

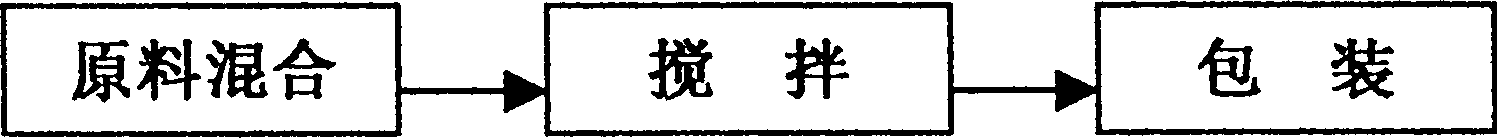

Method used

Image

Examples

Embodiment 1

[0020] The invention is prepared from weather-resistant high polymer resin A, filler, auxiliary agent, diluent and weather-resistant high polymer resin B in a weight ratio of 10:15:25:45:5.

[0021] The weather-resistant high polymer resin A described in the present invention is a hydroxyl polymer or a silicon-modified hydroxyl polymer or a fluorine-modified hydroxyl polymer, such as produced by COLYOS, Germany.

[0022] The filler of the present invention is talcum powder or calcium carbonate powder or bentonite, such as the talcum powder produced by Guangzhou Sulfuric Acid Factory.

[0023] The auxiliary agent described in the present invention is a leveling agent or a thixotropic agent, such as the leveling agent produced by BYK.

[0024] The diluent of the present invention is weakly soluble aliphatic hydrocarbon, as produced by Shell Plant.

[0025] The weather-resistant high polymer resin B of the present invention is diuretic polymer, such as produced by Bayer factory....

Embodiment 2

[0027] The invention is prepared from weather-resistant high polymer resin A, fillers, additives, diluents and weather-resistant high polymer resin B in a weight ratio of 9:13:28:46:4.

[0028] The raw material of the present invention is easy to obtain, easy to construct, has extremely strong water resistance, can penetrate into the cement base and organically combine with the coating, and is completely integrated with the plastering base of the coating; it has strong adhesion, stable chemical properties, and mildew resistance , strong self-cleaning function, can better adapt to various climate changes, is an important form of modern chemical coatings as architectural finishing, and has the advantages of both organic coatings and inorganic coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com