Laser hole-making method for non-metal thin type material and its equipment

A thin material, non-metallic technology, applied in the field of laser drilling of non-metallic thin materials, can solve the problems of not having a good drilling method and equipment, and achieve the effect of consistent pattern, flexible layout and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

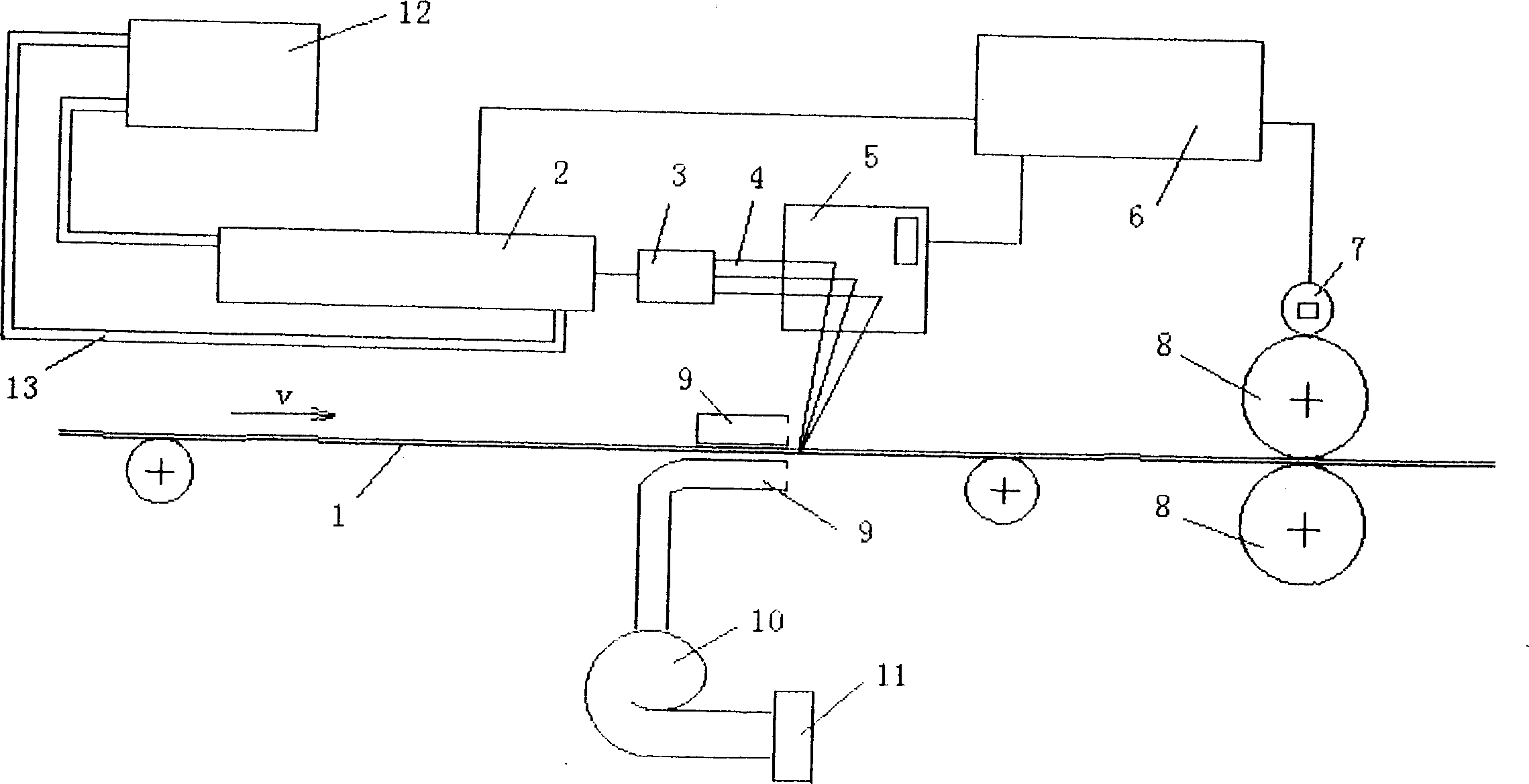

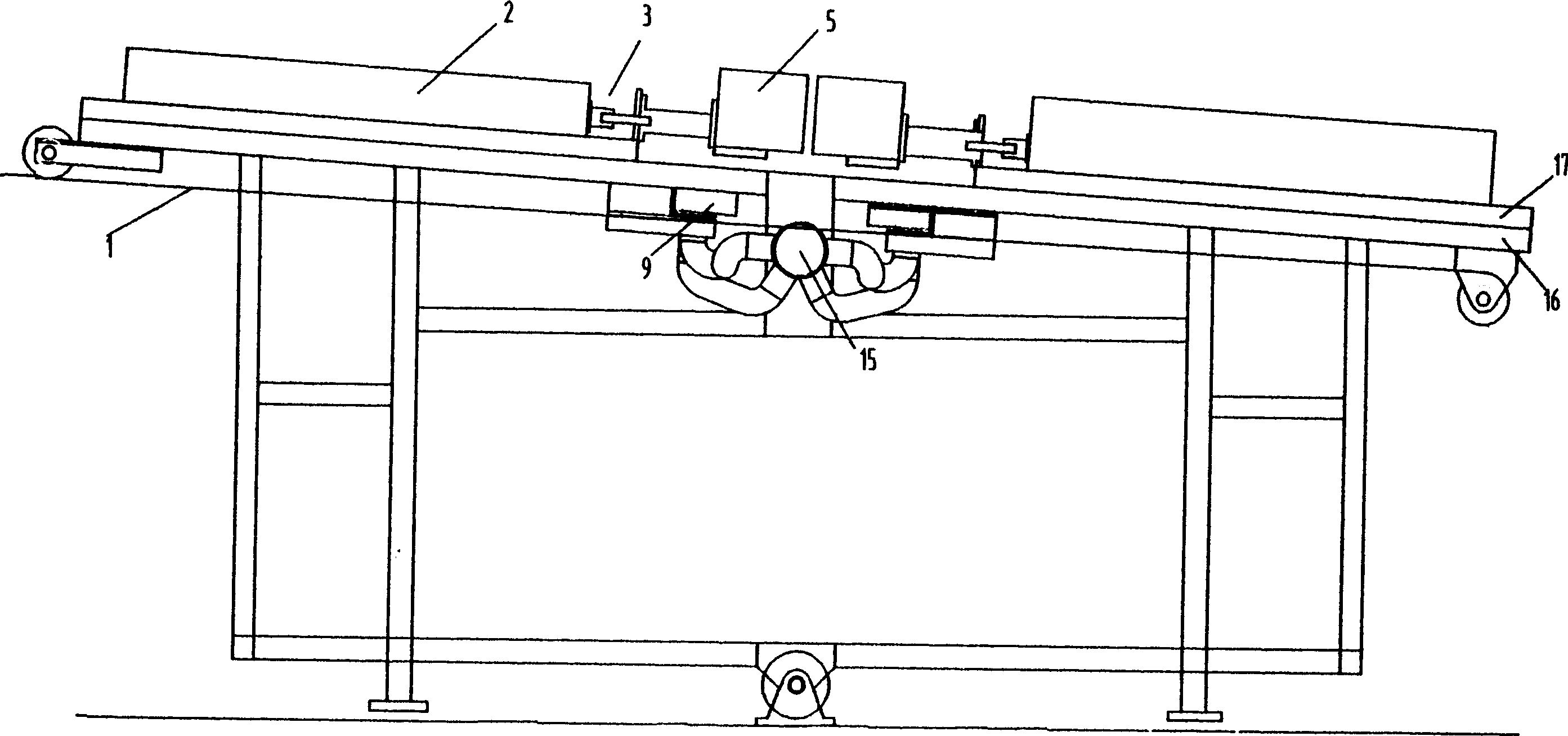

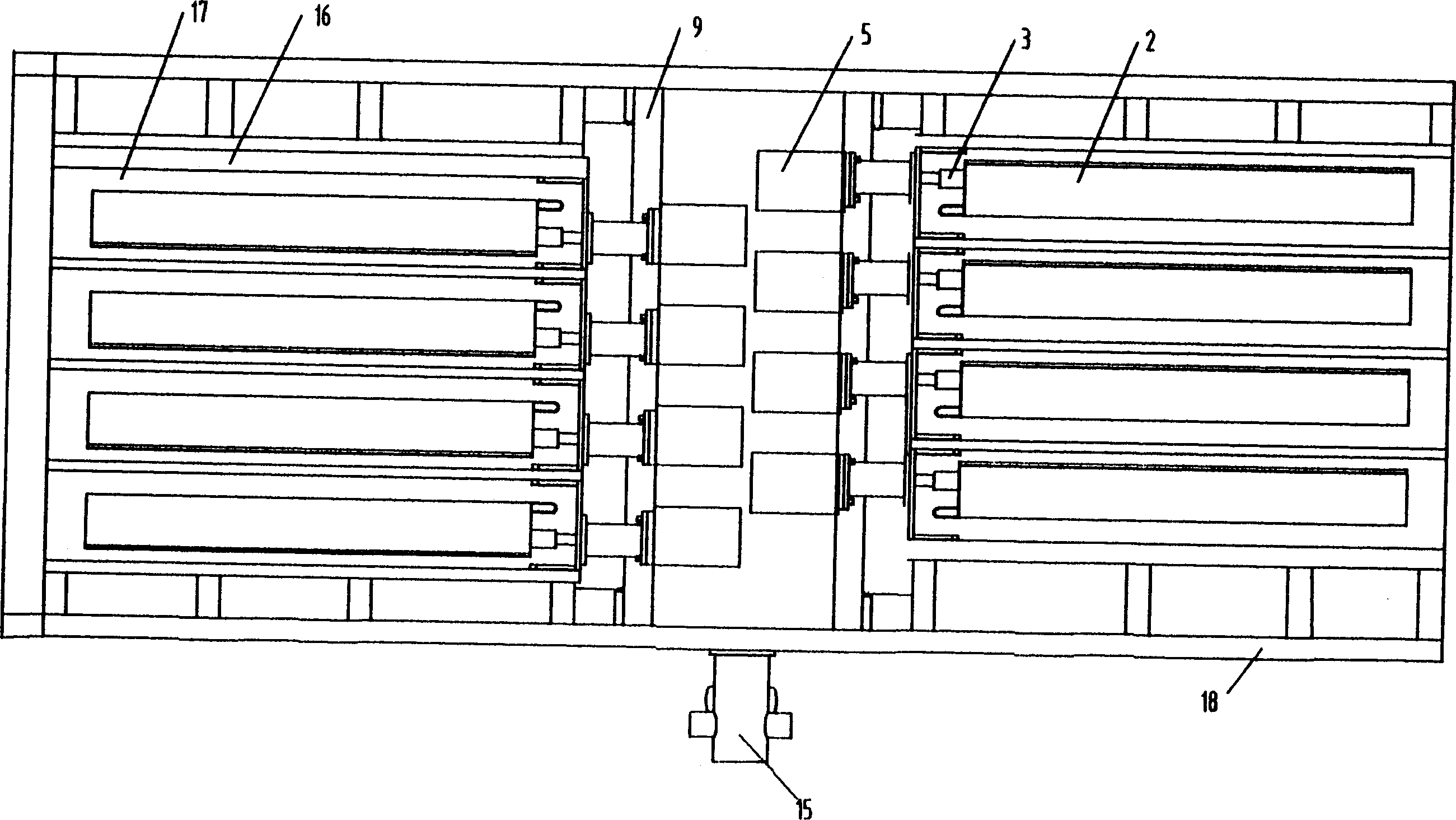

[0025] The method of the present invention selects the hole-making method of punching or cutting holes according to the hole-making requirements; and by setting the program parameters of the control device, the control device controls the laser power, and adjusts the size of the hole by controlling the movement track of the beam deflection system , density and pattern.

[0026] During dynamic hole making, the position of the hole is dynamically changed due to the continuous movement of the material. In order to ensure that the hole making pattern is consistent when the material is moving at different speeds, the method of online detection of the displacement and moving speed of the material is adopted. According to the detected material displacement, the displacement compensation amount is calculated in real time, and the beam deflection system for hole making is dynamically compensated and corrected; and according to the detected material movement speed, the hole making device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com