High polymer electrolytic shape fuel cell

A polymer electrolyte and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve problems such as unfavorable volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

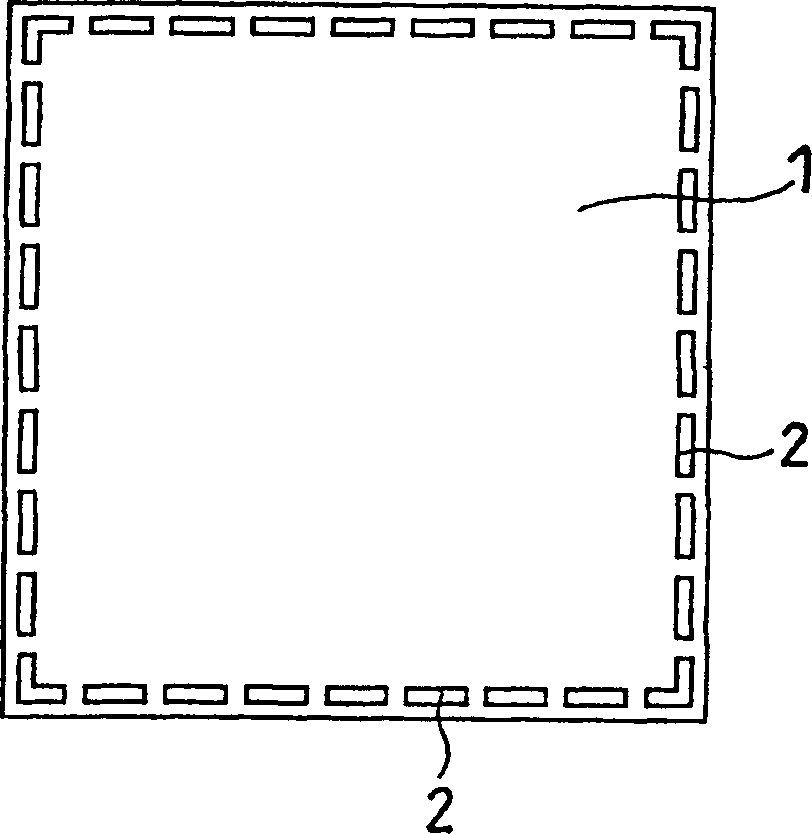

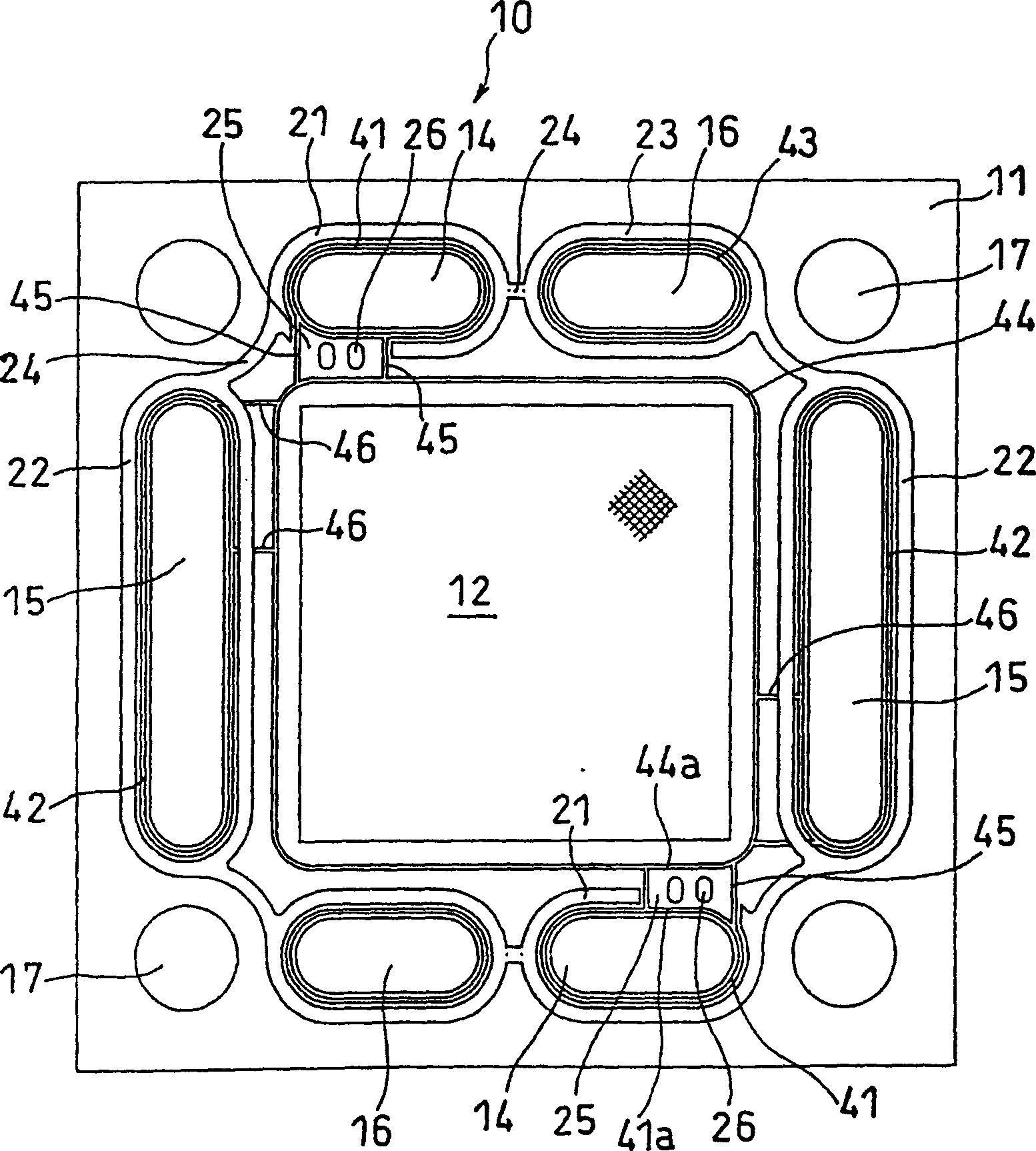

[0088] The front view of the anode side of the MEA in this embodiment is as follows figure 2 As shown, the front view of the cathode side is shown in image 3 shown. The MEA10 consists of figure 1 The polymer electrolyte membrane 1 shown is composed of a gasket 11 covering its peripheral portion, an anode 12 bonded to one side of the polymer electrolyte membrane 1 , and a cathode 13 bonded to the other side of the polymer electrolyte membrane 1 . The polymer electrolyte membrane 1 has through-holes 2 arranged in a peripheral portion. In order to cover the peripheral part including the through hole 2 part of the polymer electrolyte membrane 1, the gasket 11 is made by injection molding, and the part covering one side of the membrane 1 and the part covering the other side are between the part surrounding the edge of the electrolyte membrane and the part covering the other side. Portions of the through-holes 2 are connected to each other, supporting the membrane 1 firmly.

...

Embodiment approach 2

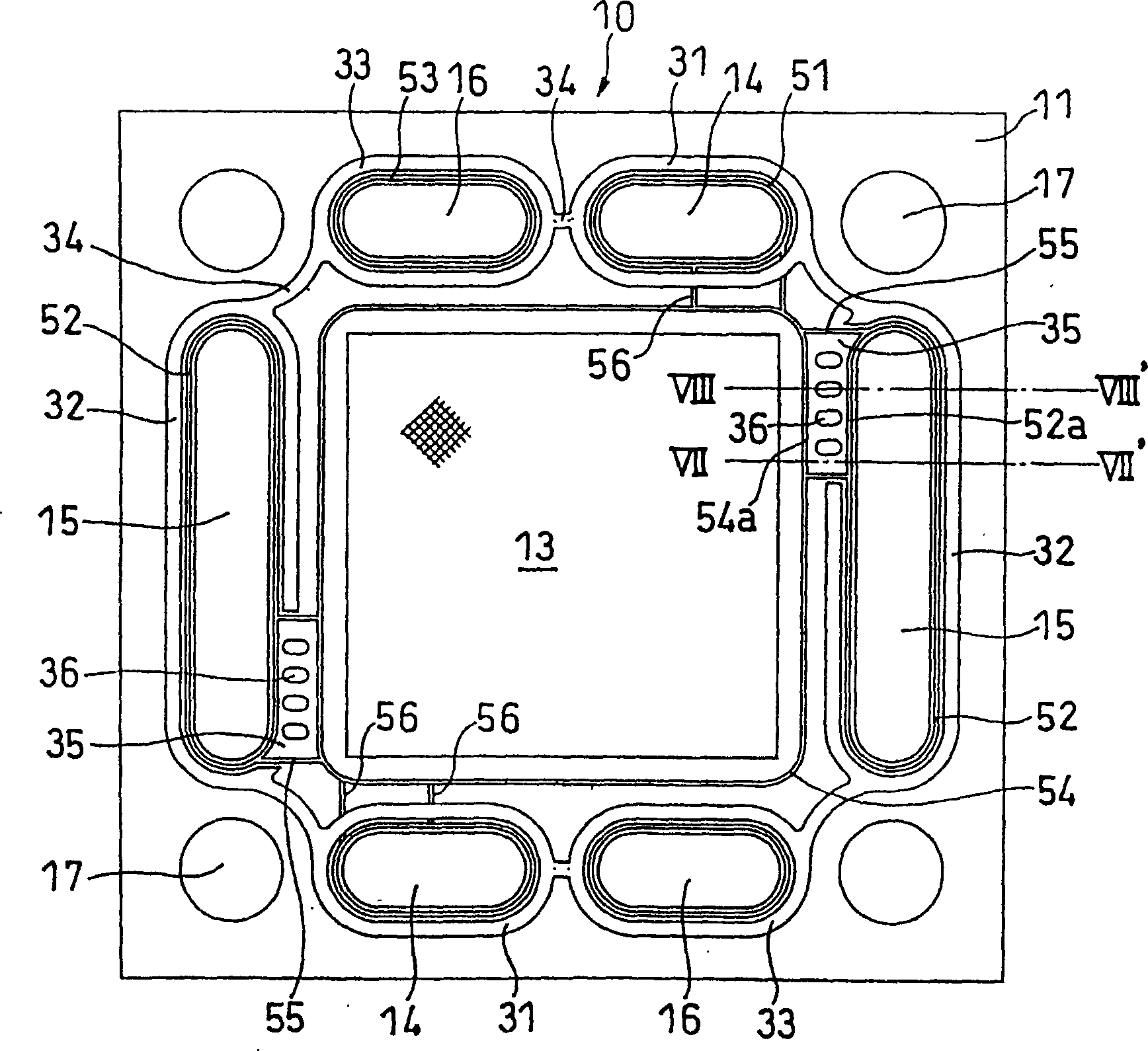

[0113] exist Figure 16 An example of making two seal ridges is shown in . Here, the sealing ridge 52 surrounding the manifold hole 15 on the cathode side of the gasket 11, the sealing ridge 54 surrounding the cathode, the sealing ridge 51 surrounding the manifold hole 14, and the sealing ridge 55 on both sides of the gas passage 35 are all made 2 pieces. Correspondingly, two sealing ridges provided on the anode side can also be formed respectively. In addition, one sealing ridge on the anode side may be provided at a position corresponding to the center of the two sealing ridges on the cathode side. As shown, the sealing effect can also be improved by making the sealing ridge into multiple strips.

Embodiment approach 3

[0115] Another embodiment of the portion connecting the oxidizing agent manifold hole 15 and the cathode of the gasket 11 will be described below.

[0116] In the above example, on the oxidant gas passage 35 of the gasket 11, four reinforcing ridges 36 are provided at almost equal intervals, and on the opposite side, ie, on the anode side, a continuous strip-shaped false ridge 22 is provided. The gas passage 35 is partially reinforced by these ridges 22 and reinforcing ridges 36 disposed perpendicularly intersecting them.

[0117] Figure 17 The gas passage 35 side is the same as above, but an example is shown in which the ridge 22a of the cylindrical shape is connected in the portion corresponding to the ridge 22 so that the strength becomes greater.

[0118] Figure 18 An example in which the diameter of the ridges 36a in the gas passage 35 is reduced but increased in number is shown. The ridge 22 on the cathode side remains in the band shape.

[0119] Therefore, various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com