Method for producing material of base plate for encapsulating integrated circuit

A technology for packaging substrates and integrated circuits, applied in circuits, metal material coating processes, electrical components, etc., can solve problems such as low dielectric coefficient and high thermal conductivity, achieve simple manufacturing process, high thermal conductivity, and improve heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

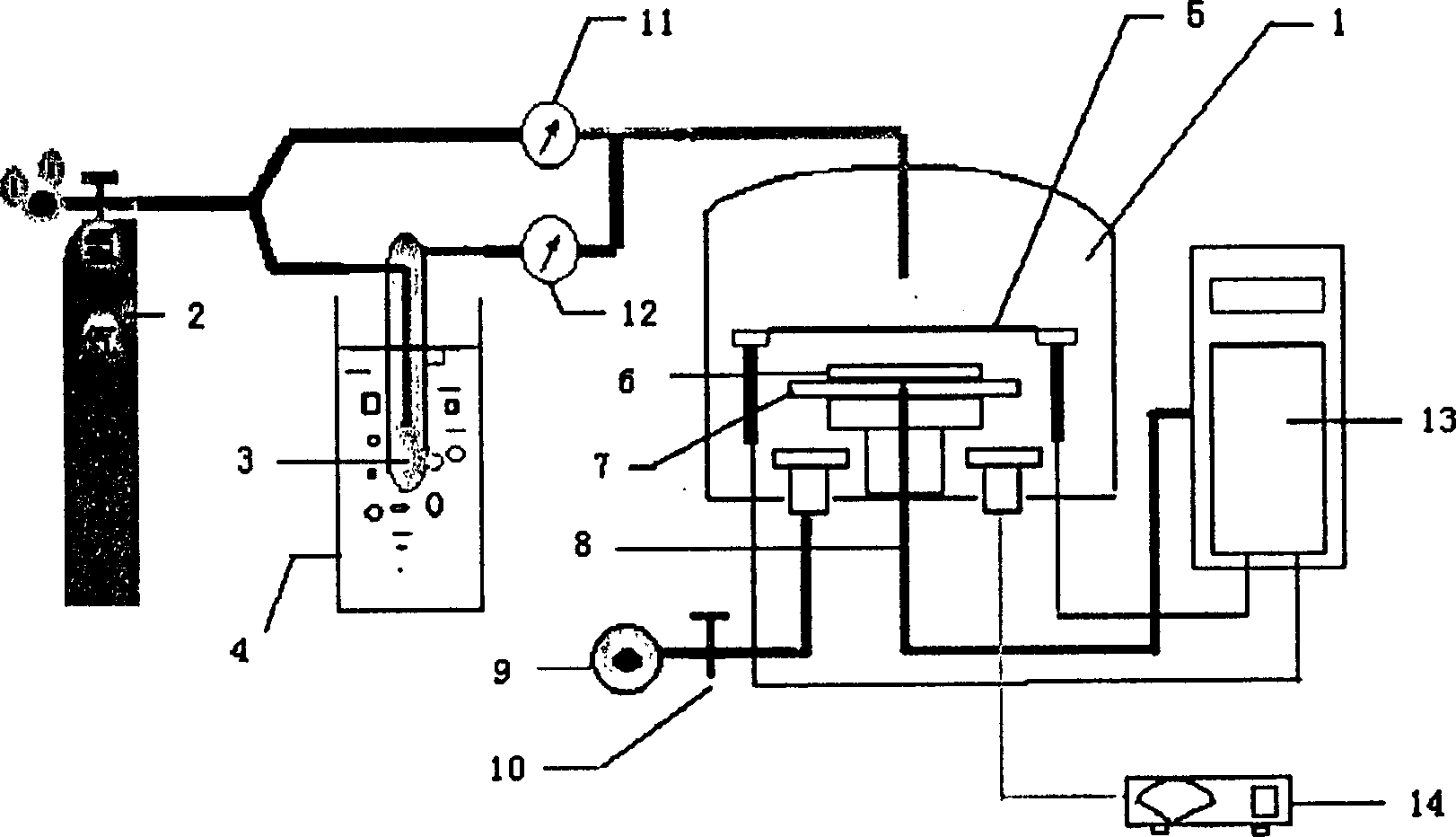

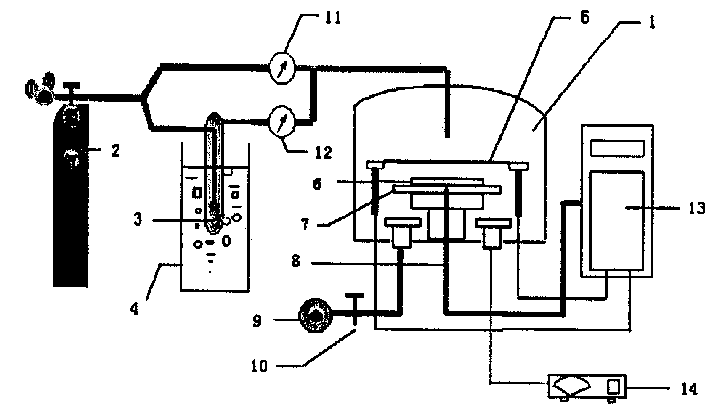

[0012] The technical solution of the present invention will be further described in conjunction with the accompanying drawings and embodiments.

[0013] Referring to Fig. 1, an alumina ceramic sheet substrate 6 is placed on the sample stage 7 in the deposition reaction chamber 1, and 16 tungsten wires 5 with a diameter of 0.4 mm are arranged above it as a heating source, and its output power is continuous Adjustable, the maximum power is 1000W, using ethanol and hydrogen as reactants. The analytically pure hydrogen in the hydrogen cylinder 2 has two output branches. One gas delivery branch is for hydrogen to pass directly into the deposition reaction chamber 1 through the mass flow meter 11, and its flow rate is controlled to be 100ml / min; the other gas delivery branch The hydrogen gas passes through the bubbling bottle 3 and draws the analytically pure ethanol in the bottle into the deposition reaction chamber 1 through a mass flow meter. A bubble bottle 3 containing analyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com