Intelligent film filter

A filter device and intelligent technology, applied in wavelength division multiplexing systems, optics, instruments, etc., can solve the problems of unfavorable cost control of systems and system manufacturers, inability to be reused, and increased production costs, etc., to achieve film thickness control The effect of reducing requirements, improving production efficiency and yield, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

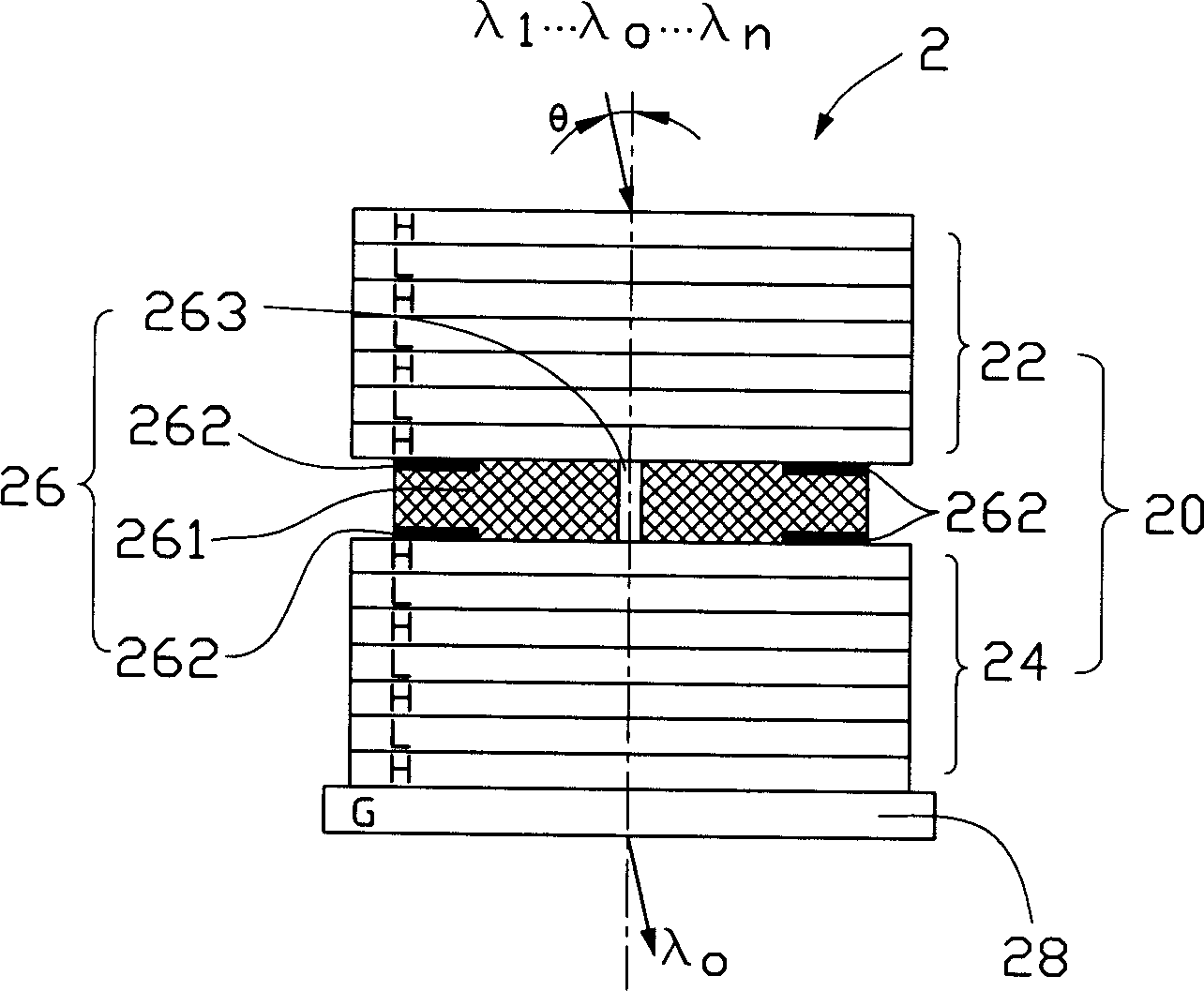

[0014] see figure 2 , is an enlarged structure diagram of the thin film filter layer 2 of the first embodiment of the intelligent thin film filter device of the present invention, which is composed of a multilayer reflective film 20 and a glass substrate 28, and the multilayer reflective film 20 includes an intermediate spacer layer 26 and two Side reflective film system 22,24. The reflective film systems 22 and 24 on both sides are alternately composed of higher refractive index n H with lower refractive index n L Two kinds of dielectric materials are superimposed, and the number of film layers can be as many as dozens of layers. The optical thickness of each alternate film layer is the preset passband center wavelength λ 0 1 / 4 times of , and its film layers adjacent to the glass substrate 28, the intermediate spacer layer 26 and the external air all have a higher refractive index n H dielectric film. The intermediate spacer layer 26 includes a space hollow layer 263 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com