Microphone, diaphragm and method for making diaphragm

A manufacturing method and technology of vibrating membrane, applied in the direction of diaphragm structure, fiber vibrating membrane, transducer diaphragm, etc., can solve the problems of high material cost of vibrating membrane, limitation of thickness, increase of material loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

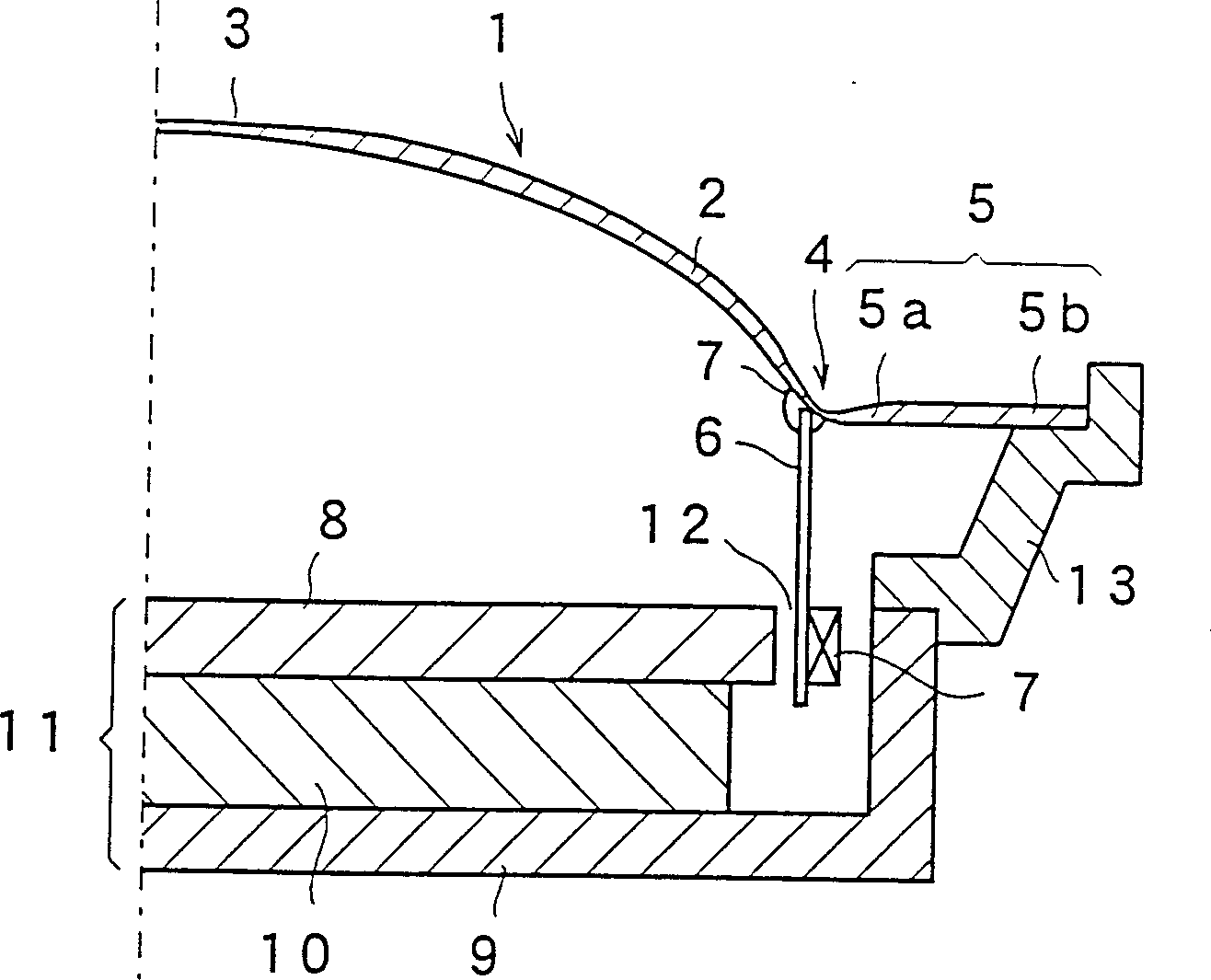

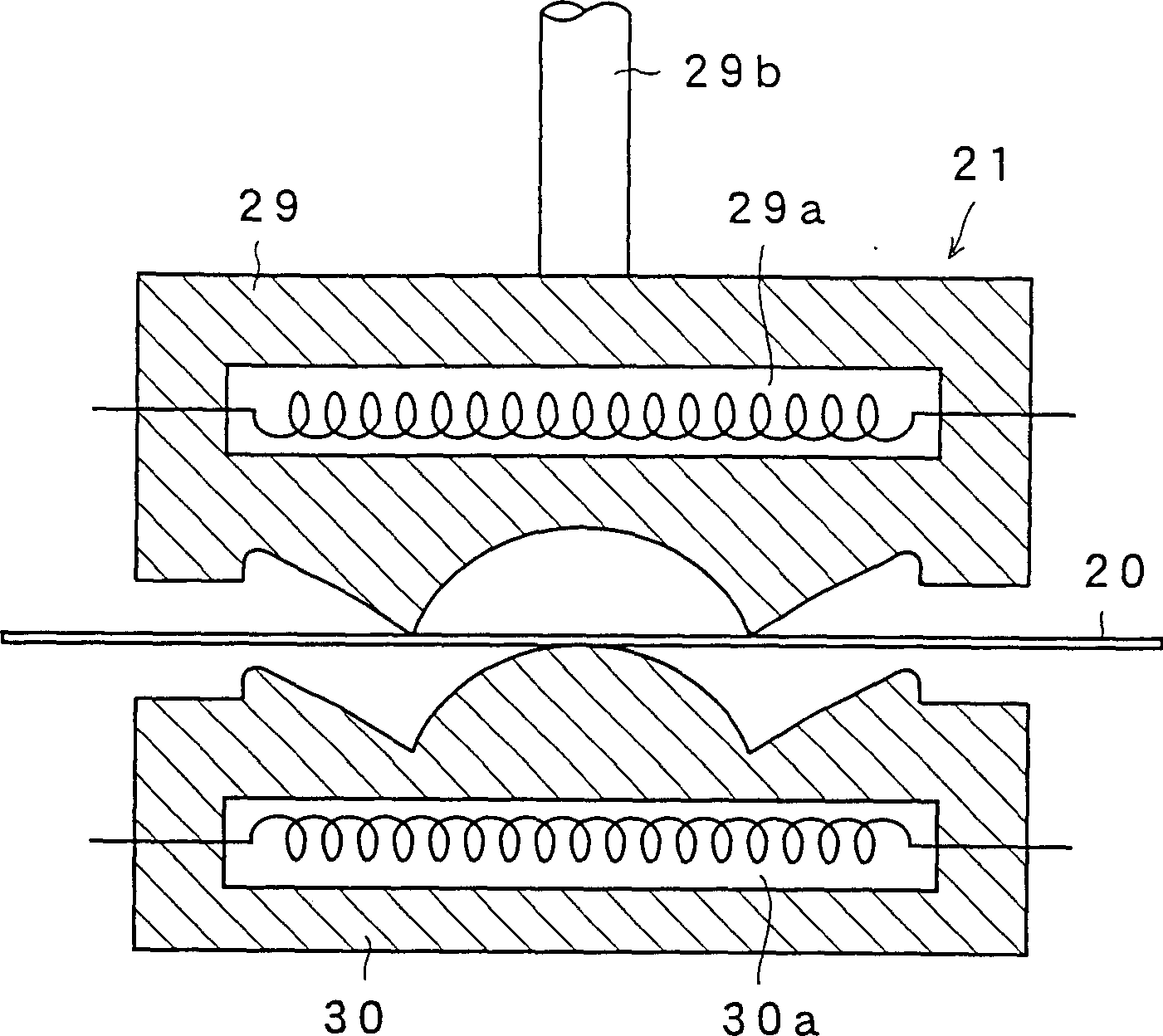

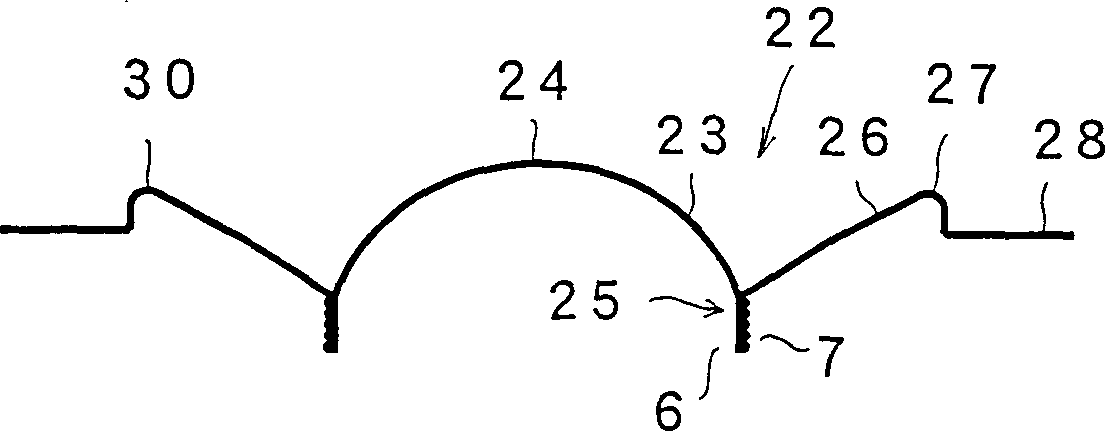

[0055] The diaphragm structure of the loudspeaker according to Embodiment 1 of the present invention will be mainly explained as follows with reference to the accompanying drawings. Here, in each figure of this embodiment, the same parts as those in the prior art are denoted by the same symbols (particularly, the magnetic circuit), and detailed description thereof will be omitted. Figure 4 is a cross-sectional view showing the structure of the loudspeaker according to the present embodiment. Figure 5 is a plan view showing the structure of the diaphragm of this embodiment. Image 6 It is a perspective view showing the appearance of the loudspeaker of this embodiment. As shown in these figures, the loudspeaker is made to include a dome-shaped diaphragm 40 in addition to a voice coil bobbin 6, a voice coil 7, a top plate 8, a yoke 9, a magnet 10, and a frame 13. Has a new cross-sectional shape.

[0056] This diaphragm 40 is made into a dome shape by melting a suitable resin...

Embodiment 2

[0061] The diaphragm structure of the loudspeaker according to Embodiment 2 of the present invention will be mainly described below with reference to the accompanying drawings. Here, in the drawings of this embodiment, the same symbols are used to designate the same parts as in Embodiment 1 and the prior art, and detailed descriptions thereof are omitted.

[0062] Figure 7 is a cross-sectional view showing half of the structure of the loudspeaker of this embodiment. In the description of this embodiment, and hereafter, the cross-sectional views show half of the main structure of the loudspeaker, since its structure is symmetrical about the axis. Such as Figure 7 As shown, the loudspeaker is manufactured to include a voice coil bobbin 6, a voice coil 7, a top plate 8, a yoke 9, a magnet 10, a frame 13 and a diaphragm 50, which has a new cross-sectional structure.

[0063] The vibrating membrane 50 is a dome-shaped vibrating membrane, and the cross-section of the dome is ar...

Embodiment 3

[0066] The vibrating membrane structure of the loudspeaker according to Embodiment 3 of the present invention will be mainly described below with reference to the accompanying drawings. Here, in the drawings of the present invention, the same parts as those in Embodiment 1 are denoted by the same symbols, and detailed description thereof will be omitted.

[0067] Figure 9 is a cross-sectional view showing half of the structure of the loudspeaker of this embodiment. As shown, the loudspeaker is fabricated to include a voice coil bobbin 6, a voice coil 7, a top plate 8, a yoke 9, a magnet 10, and a frame 14 and a diaphragm 60 having a new cross-sectional shape.

[0068] The vibrating membrane 60 is obtained by combining the dome-shaped vibrating membrane and the conical vibrating membrane into one body, and the cross-section of the dome-shaped vibrating membrane is Figure 9 The circular arc is shown, while the conical diaphragm includes a conical portion. The vibrating memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com