Deposited thin film and their use in separation and sarcrificial layer applications

A deposition, volume ratio technology that can be used in microstructure devices composed of deformable elements, coatings, fuel cell components, etc., to solve problems such as difficulty in manufacturing small groove sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

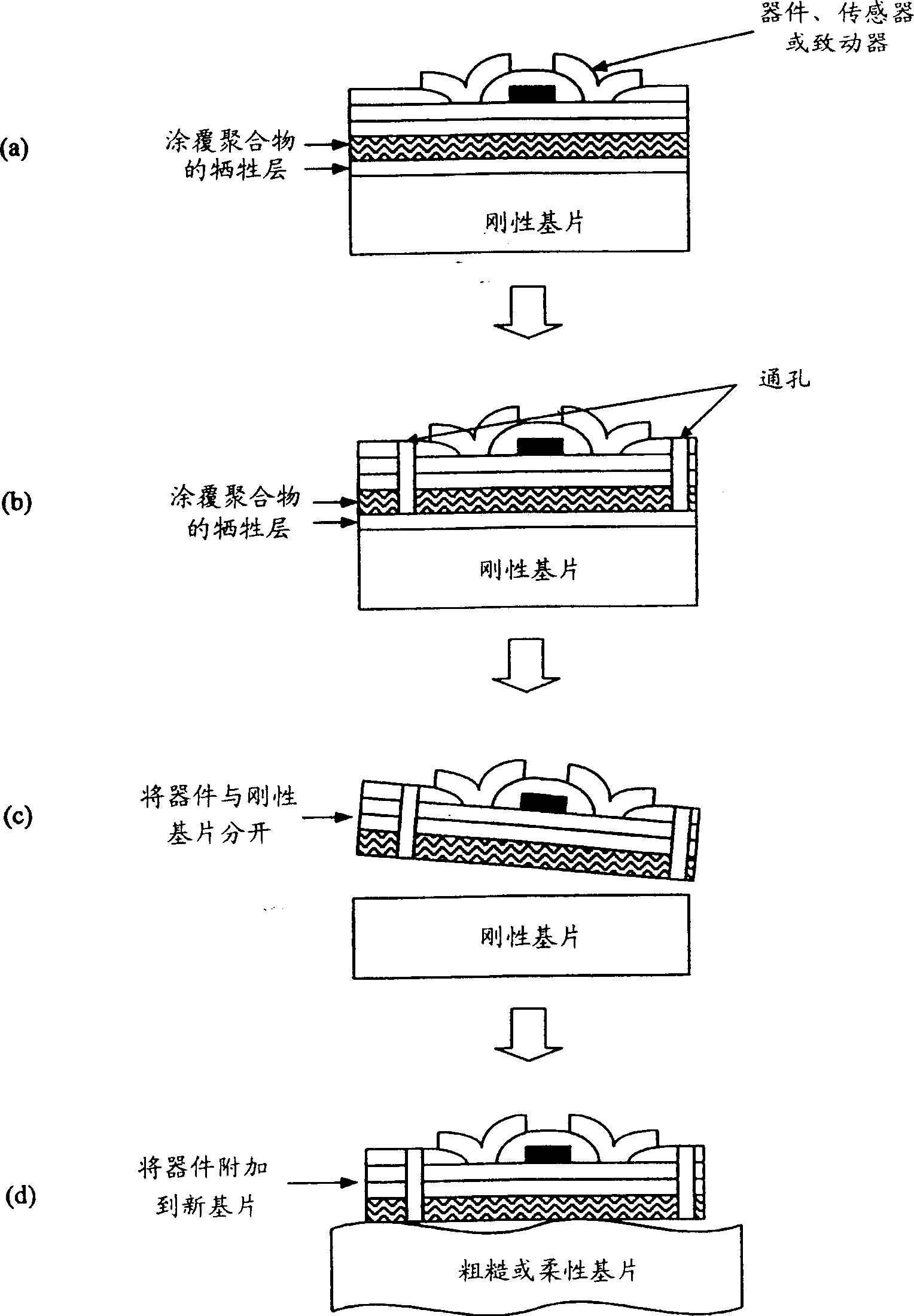

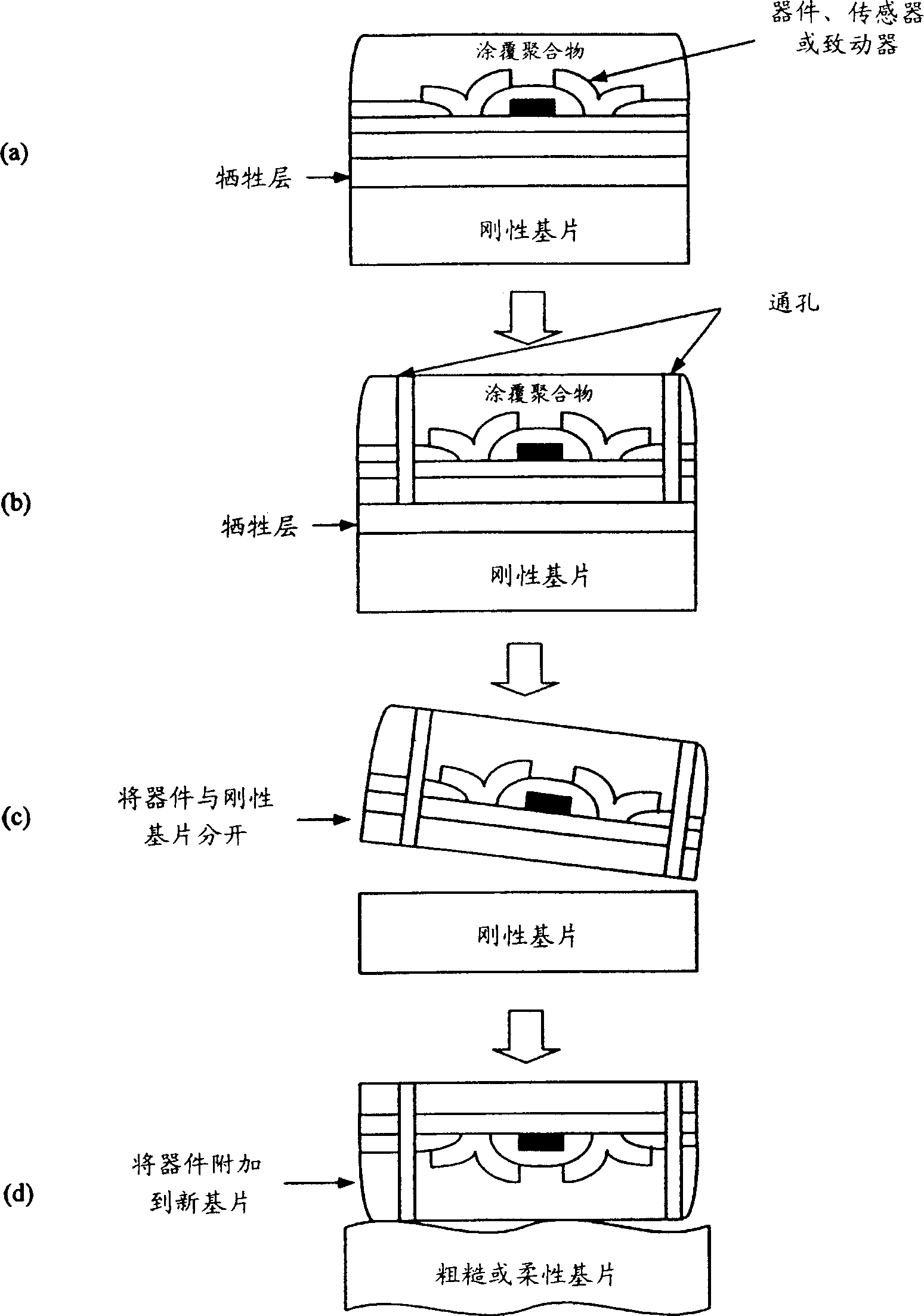

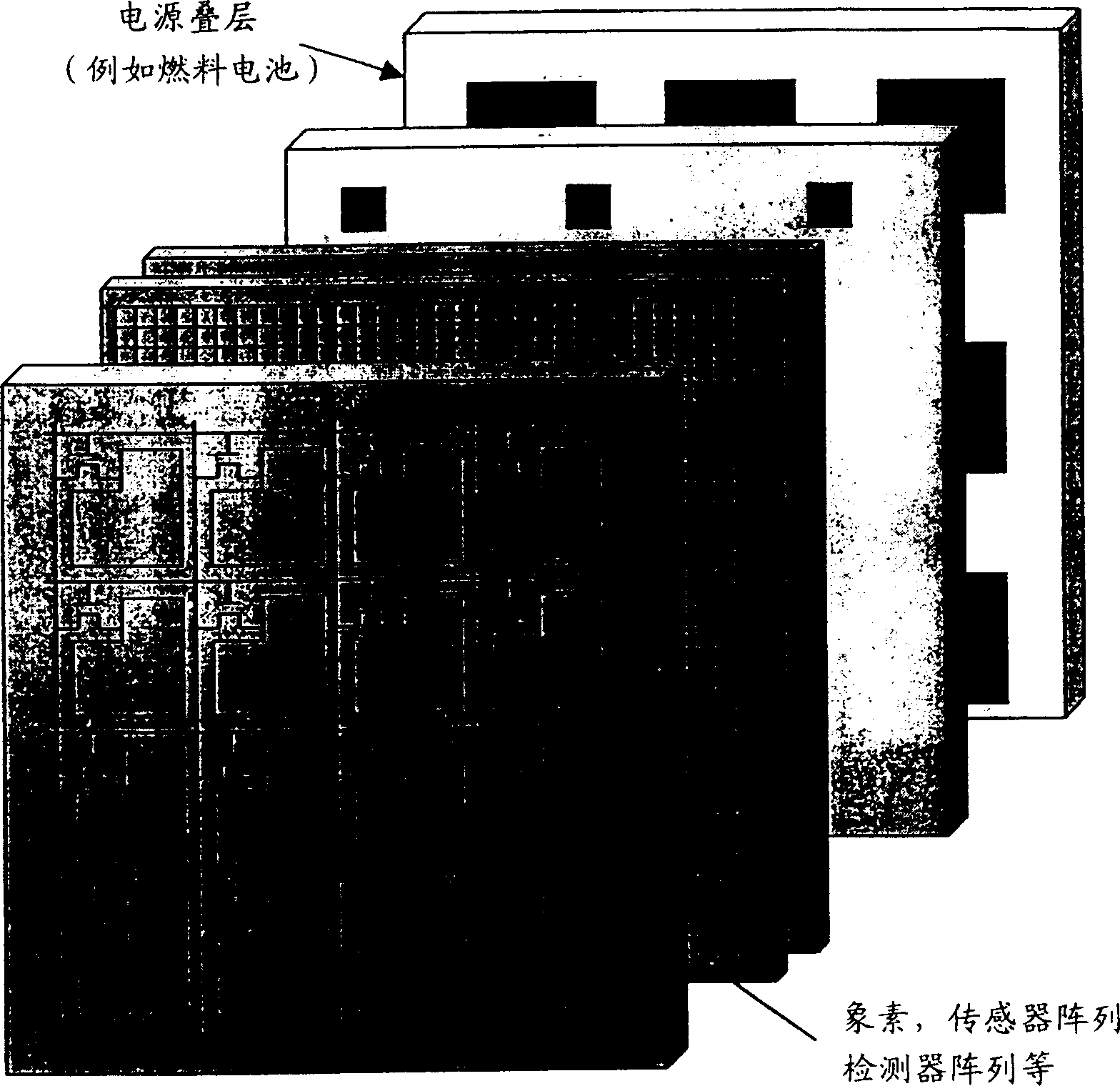

Method used

Image

Examples

Embodiment Construction

[0046] The method of fabricating materials with large pore volumes and thus large surface area to volume ratios in the present invention is to use deposition to grow deposited porous membranes. In the present invention, the void regions (pores) are suitably uniformly distributed over the thickness of the membrane and across the membrane. The deposition process is unique in that it is performed at low temperatures. The inventors have shown that the present invention can control pore size and porosity. The pore columnar network morphology does not change over the thickness of interest. Columns can be polycrystalline or amorphous. crystal material. Plasma methods including dc and rf discharge, sputtering and high density plasma equipment are used to control the interplay between deposition and etch during growth. High porosity (up to nearly 90%), controlled pore size materials can be obtained using high density plasma deposition etch interoperable process without any back contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com