Extraction process of acetylated aloe glucomannan

A technique for extracting acetylated glucomannan from aloe, which is applied in the field of extraction of acetylated glucomannan from aloe, and can solve the problems of extraction, separation, and purification that are very difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

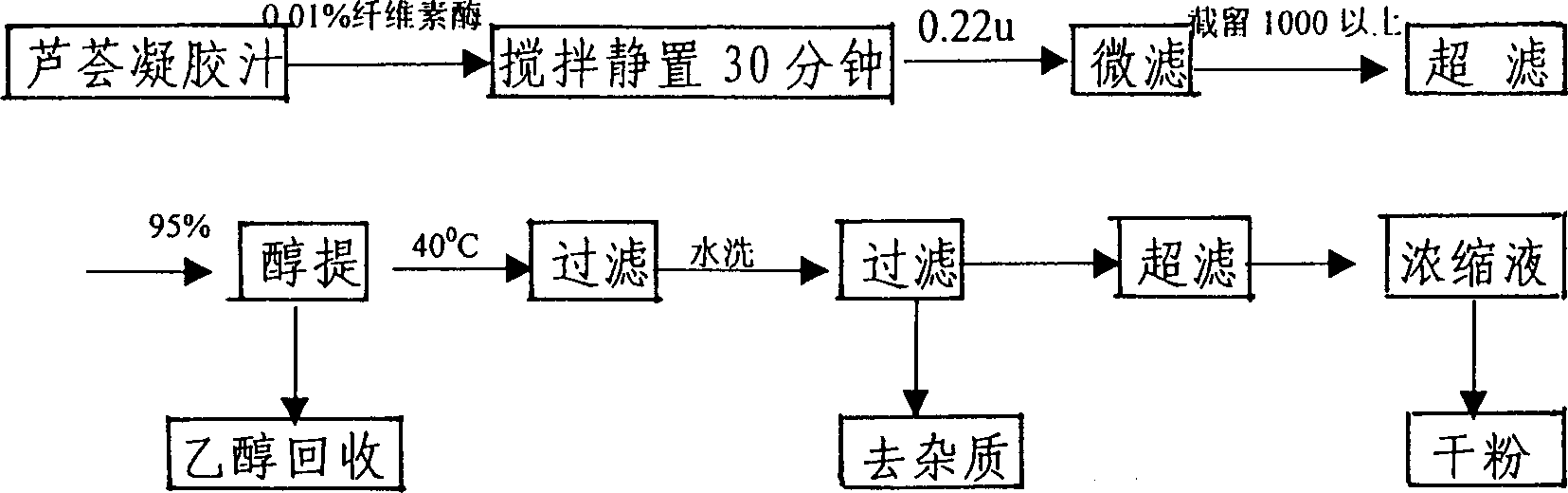

Image

Examples

Embodiment Construction

[0010] Take 2000 kg of aloe vera gel juice in the mixing tank, add 0.01% or 0.2 kg of cellulase, stir evenly, keep warm at 40°C for half an hour, and then use a pump to inject 0.22u microporous membrane modules for microfiltration and microfiltration of the dialysate After filtering through the ultrafiltration membrane, when the ultrafiltration concentrate is 100 kilograms, stop the ultrafiltration assembly, put 100 kilograms of concentrated juice into a 1.5 ton mixing tank, add 1000 kilograms of 95% ethanol, stir for 5 minutes, and let stand for 3 hours. Then filter with a filter, recover ethanol, transfer the precipitate to a 100L stirring tank, wash the filter cloth 3 times with water, transfer the washing water to the stirring tank, add water to 50L, and then concentrate with a small ultrafiltration membrane module, when the concentrated solution is 10L When the operation is stopped, the pure aloe acetylated glucomannan concentrate is collected. 10L of concentrated juice w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com