Regeneration process technology for sewage in refinery

A technology for treating process and refining sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of rapid water quality decline in circulating cooling water systems and the inability of reductive pollutants Removal, difficult to achieve long-term reuse and other problems, to achieve the effect of low infrastructure and operating costs, significant removal effect, and good novelty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

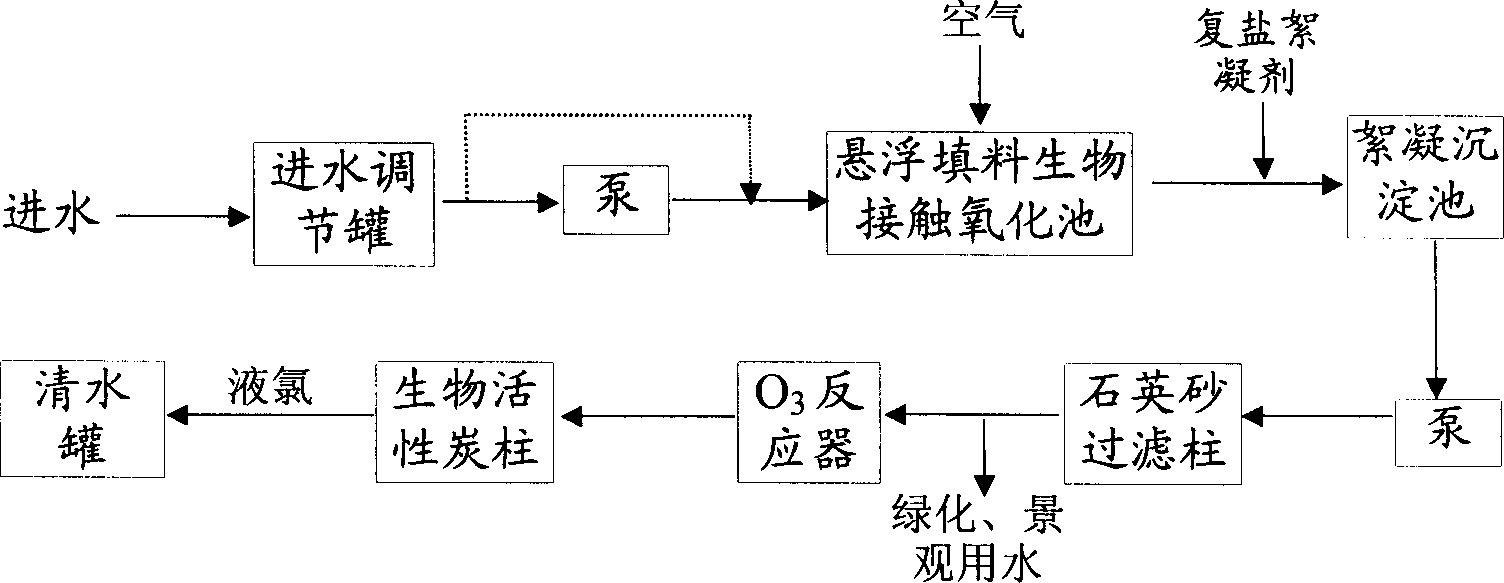

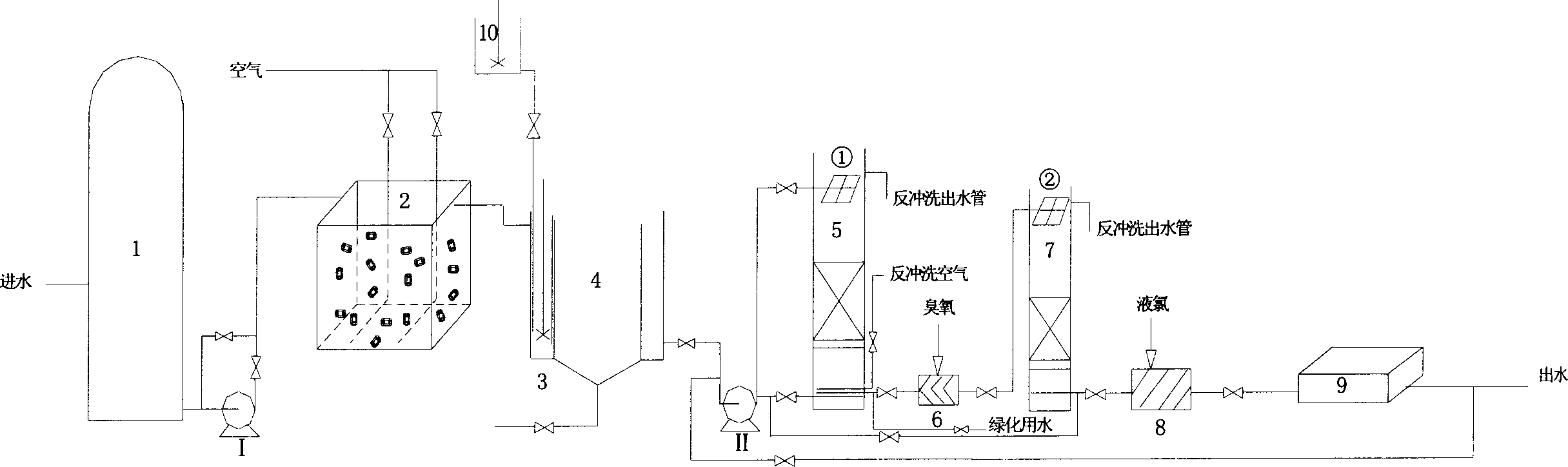

Method used

Image

Examples

Embodiment

[0071] In 2000, a refining and chemical company adopted the process of the present invention to establish an operating device with a daily water treatment capacity of 12 to 24 tons of external drainage. The results of 8 consecutive months of stable operation show that the process has strong decontamination ability and the water quality after sewage regeneration treatment is excellent. , and the removal effects of the main pollutants are shown in Table 1.

[0072] Table 1. Changes in pollutant concentration before and after sewage regeneration (multi-month average)

[0073] It can be seen that this process has a good removal efficiency for the pollutants in the external drainage. After the sewage is regenerated, it is clear and colorless, the concentration of pollutants is very low, and the number of bacteria is small. It can be used as industrial fresh water and domestic miscellaneous water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com