X ray apparatus high voltage generator microcomputer control debugging method

A technology of high-voltage generator and debugging method, which is applied in the field of medical instruments, to achieve the effects of reducing service life, preventing pollution, and simple structure of hardware equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

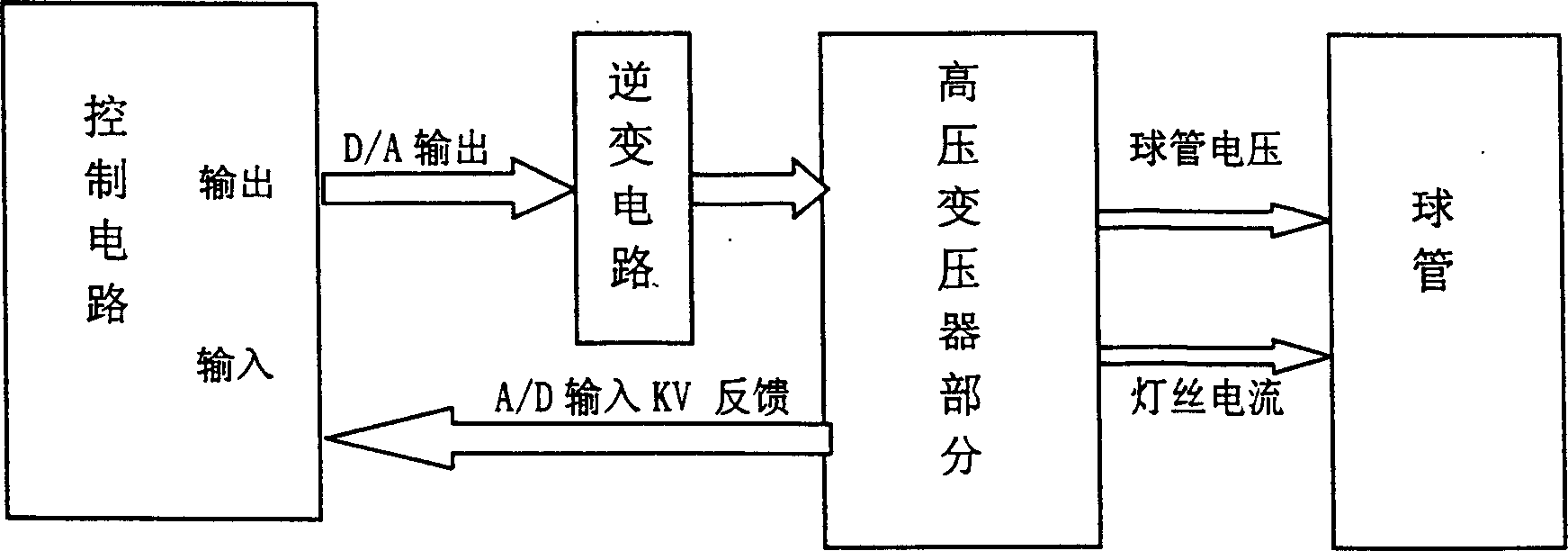

Method used

Image

Examples

Embodiment Construction

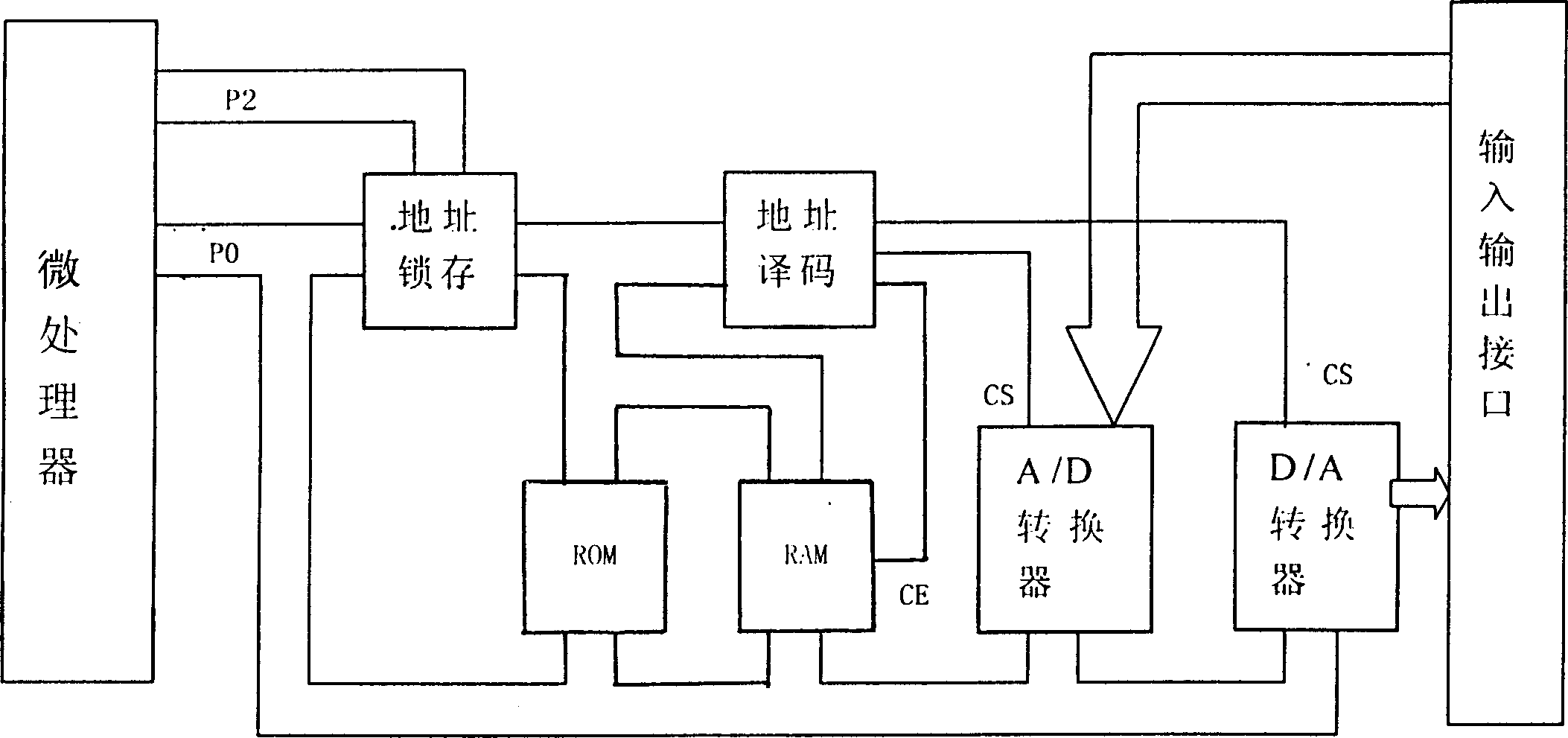

[0018] Replace ordinary RAM memory chips with memory chips with lithium batteries

[0019] Replace the original chip HM62256(32K) with DS1230Y chip

[0020] Replace the original chip HM628128 (128K) with HK12DP45 chip.

[0021] Chip storage content: tube voltage (KV value): 40KV-150KV;

[0022] Tube current (mA value): 0-500mA;

[0023] Tube filament current: 0-6A;

[0024] Each exposure time of the tube: 0-6300 milliseconds (ms)

[0025] Tube data and limit parameters: the maximum heat capacity of the tube, the maximum size of the filament

[0026] High power, maximum tube voltage, etc.;

[0027] The return value of the actual working voltage of the tube and the return value of the tube current.

[0028] Data and debug example:

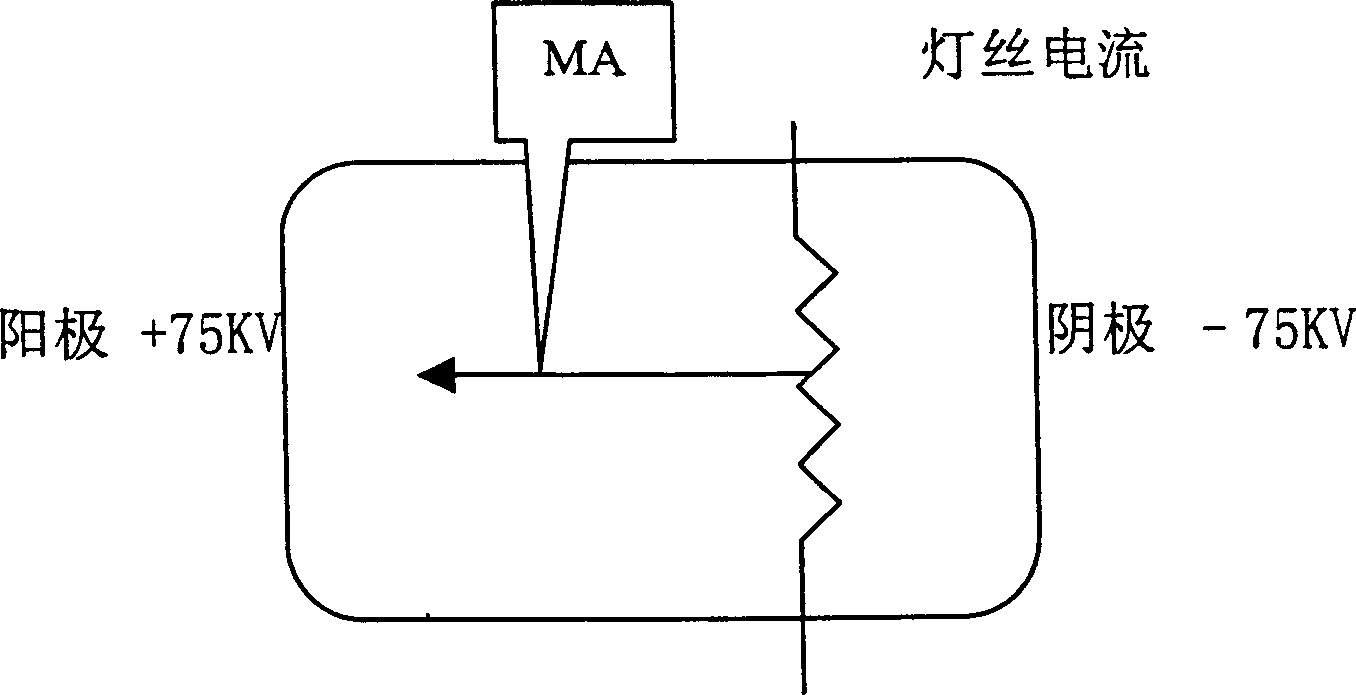

[0029] 1. KV, MA feedback value test

[0030] KV MV standard value 20KV=1V 100mA=1V2, the actual tube voltage accuracy test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com