Design and manufacturing technique of micro optical eye glass and glasses

A manufacturing process and micro-optical technology, which is applied to the design and manufacturing process of micro-optical spectacle lenses and the field of lenses, can solve the problems of inconvenient use, too thick and heavy lenses, and failure to effectively promote them, and achieve the effect of beautiful price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

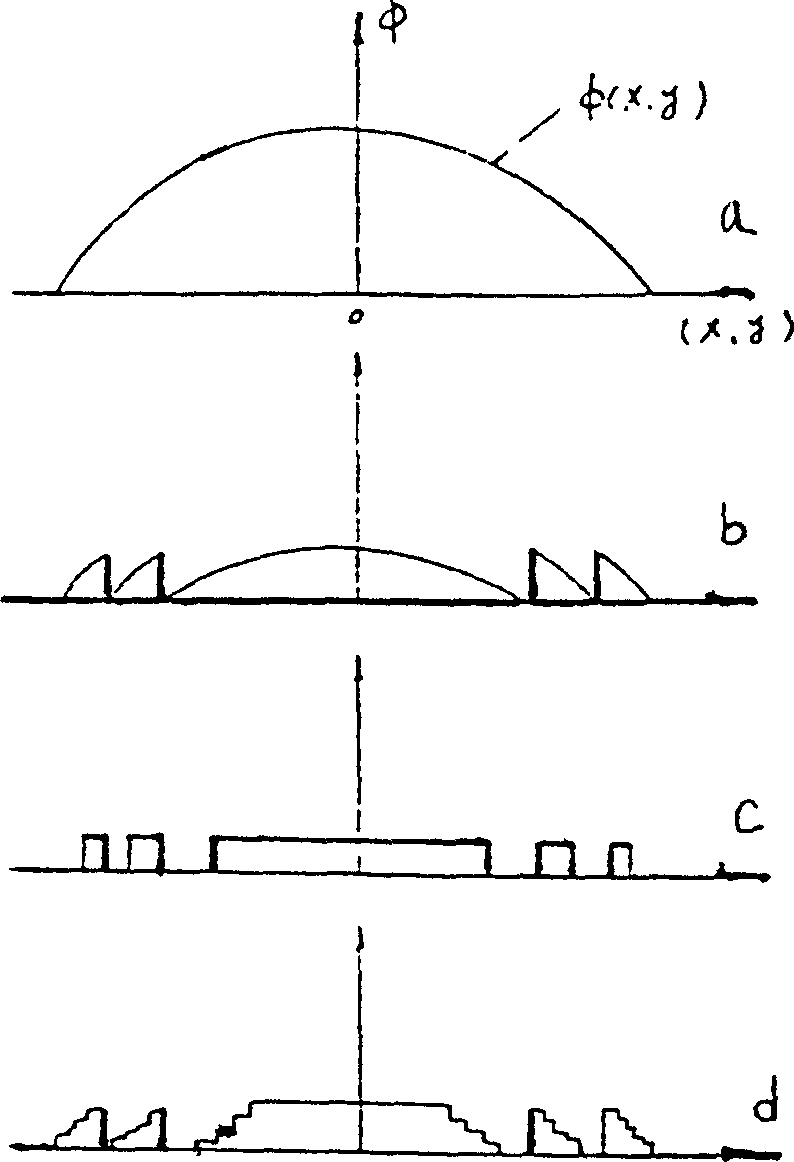

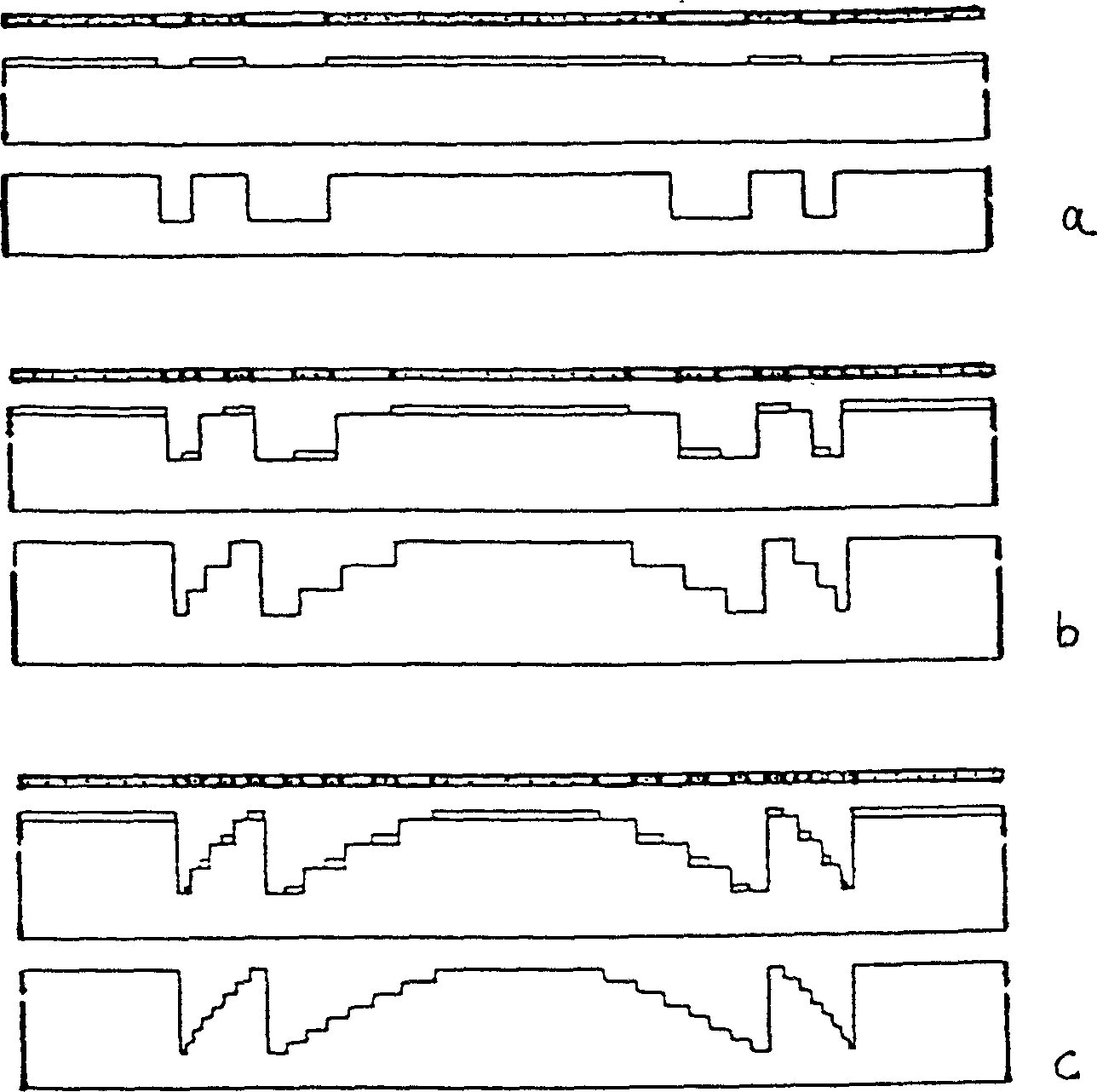

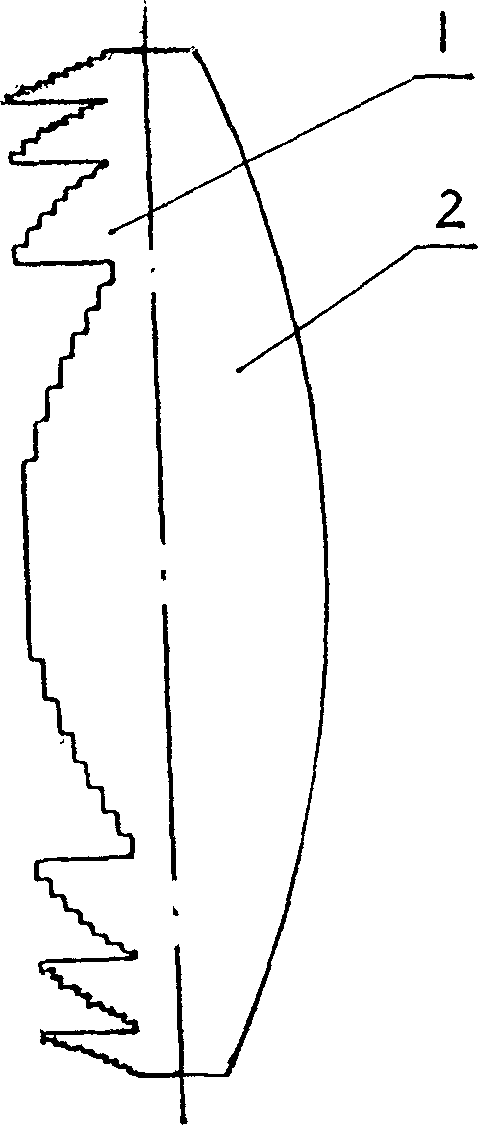

[0027] Example 1. This example is +7.0m -1 The design and manufacturing process of hyperopia lenses, using a pair of molds, of which +3.0m -1 Formed by the mold surface of ordinary hyperopia lens, +4.0m -1 Formed by the surface of the micro-optical replication mold, the design and production methods of the micro-optic replication mold are as follows:

[0028] 1) Photolithography mask: According to the principle of optics, the diopter is +4.0m -1 The focal length of the hyperopia lens is f=200mm, and the optical aperture parameter is 30mm. Using photoresist ( # 1350) photolithographic chromium plate, using electron beam lithography machine or laser direct writing equipment to make three masks according to the software designed according to (A), the minimum line width of the edge is controlled to 1 μm, and the ring diameter is gradually increased to r k =(2kλf) 1 / 2 , where the number of rings K=1, 2, 3...λ-wavelength of incident light, f-focal length.

[0029] 2) Ion etch...

Embodiment 2

[0032] Example 2. This example is +6.0m -1 The design and manufacturing process of hyperopia and +200 degree astigmatism lens. Comparing with Example 1, in the designed software, substitute corresponding parameters, according to meridian plane+6.0m -1 Focus length design microstructure, according to the sagittal plane +2.0m -1 The focal length designs the microstructure and makes it on the mask to make a pair of manufacturing molds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com