Rolled member head shape controlling method

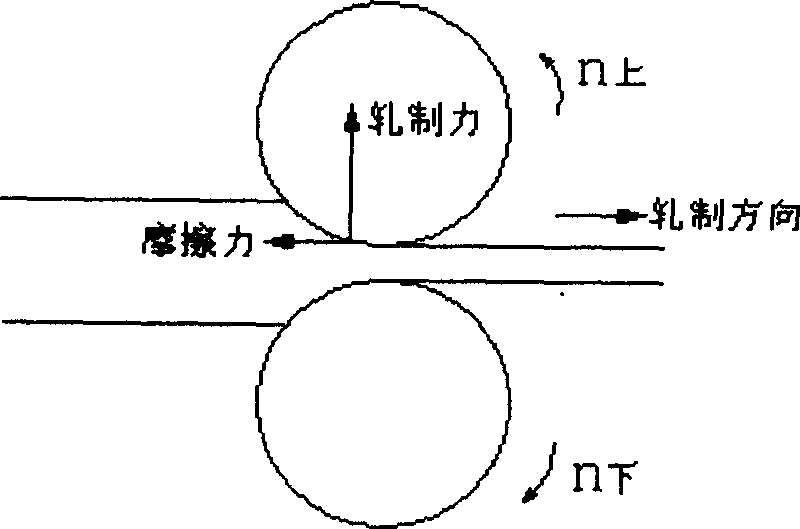

A technology of head shape and control method, applied in the direction of tension/pressure control, etc., can solve the problems of upturning or buckling of the rolled head, affecting normal production, accidents, etc., to speed up the production rhythm, reduce the labor intensity of workers, The effect of increasing the rolling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

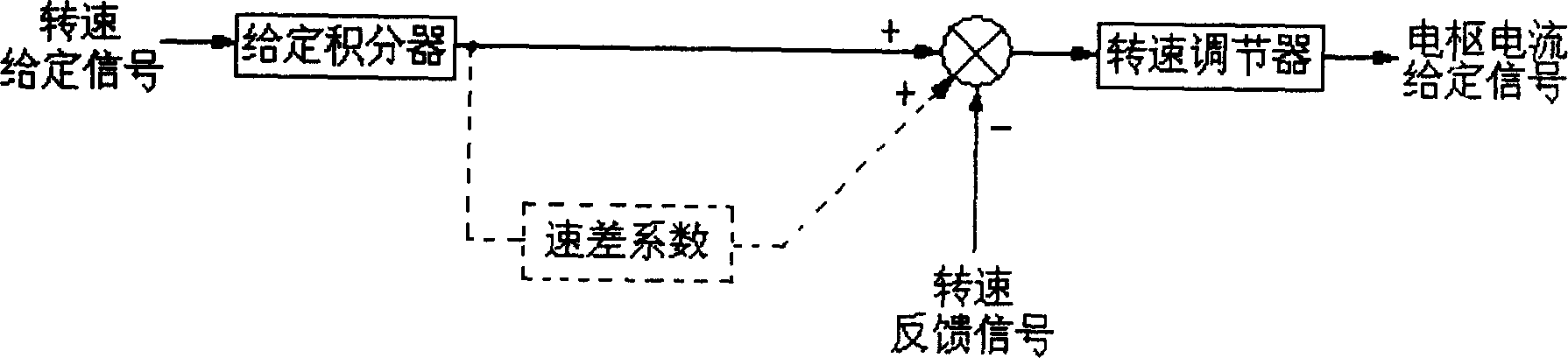

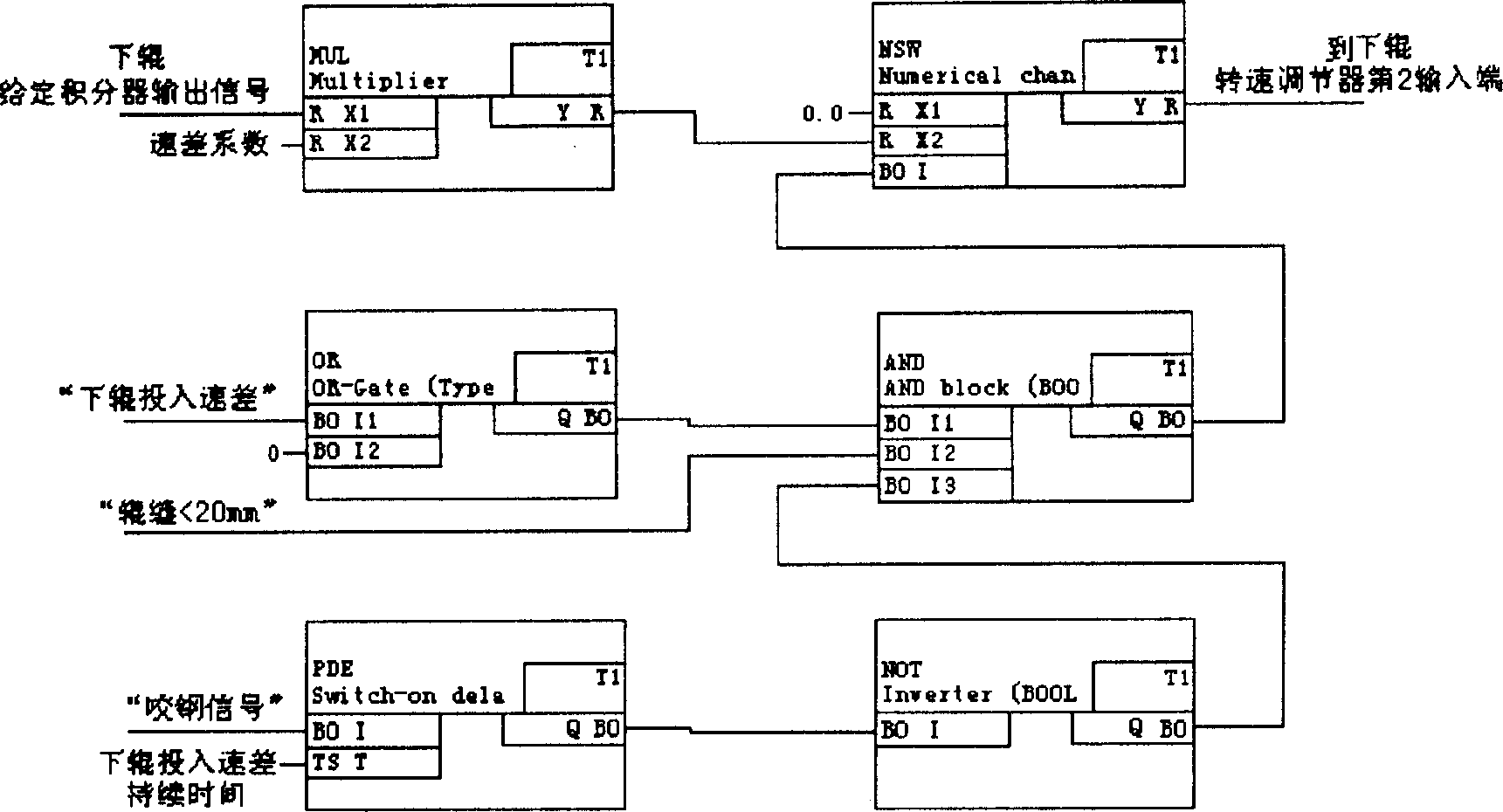

[0021] Embodiment 1 is an improved method on the basis of the first technical scheme, image 3 It is the software structure diagram, and the speed control system of the following work rolls is taken as an example. The SIMADYN D full digital control system of Siemens is used to form the main motor speed control system. Among the software function blocks used in the SIMADYN D full digital control system, X, X1, and X2 are input terminals, and the data type is real number R; Y is output Terminal, the data type is real number R; I, I1, I2, I3 are input terminals, the data type is logical quantity BO; Q is the output terminal, the data type is logical quantity BO; T is the input terminal, the data type is time TS, the unit ms; in image 3 in, corresponding to figure 2 In the dotted line, the output signal of the lower roll set integrator is multiplied by the multiplication function block MUL and the speed difference coefficient, and the corresponding speed difference setting is ...

Embodiment 2

[0022] Example 2 as Figure 4 As shown, the following work rolls are taken as an example. exist Figure 4 The MFP pulse generator function block is used in the system. When the "steel biting signal" is 1, the Q terminal of the MFP is 1, and becomes 0 after the set "lower roll input speed difference duration". When the I terminal is 0, its Q terminal is 0; as long as the I1, I2, and I3 terminals of AND are all 1, the speed difference setting is enabled, otherwise it is not enabled.

Embodiment 3

[0023] Example 3 as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com