Automatic producing interlink machine unit of radialply tire inner lining thin film

A radial tire, automatic production technology, applied in tires, other household appliances, household appliances, etc., can solve the problems affecting the internal quality and production efficiency of radial tire products, expensive equipment, imported equipment functions that cannot adapt to and meet domestic production processes, etc. problems, to achieve the effect of saving equipment investment, improving internal quality, and high centering precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

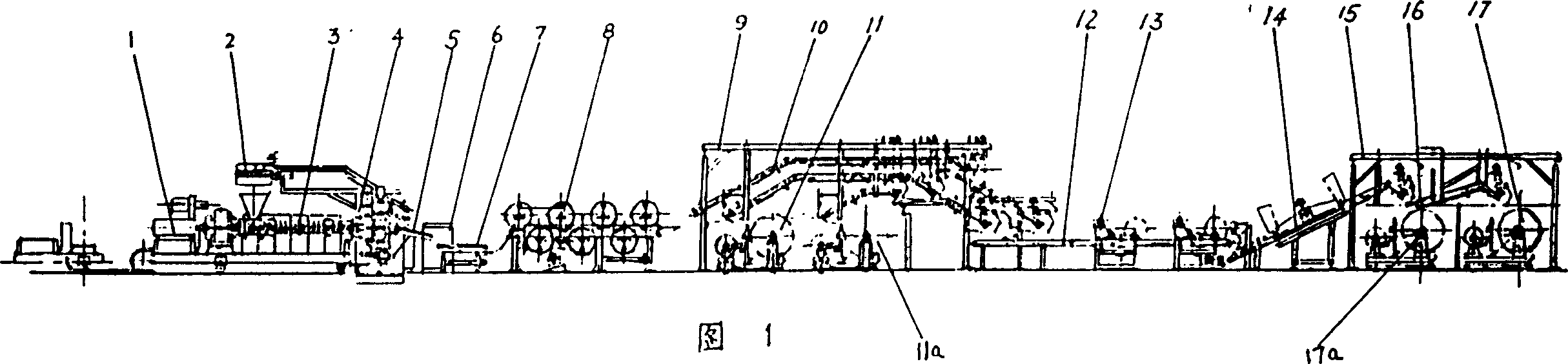

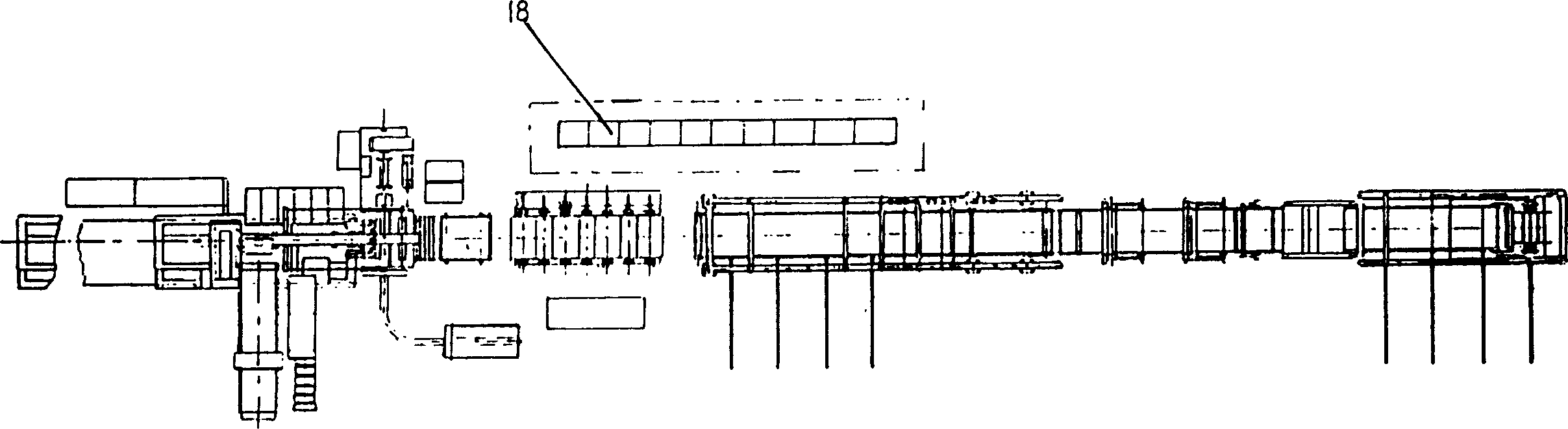

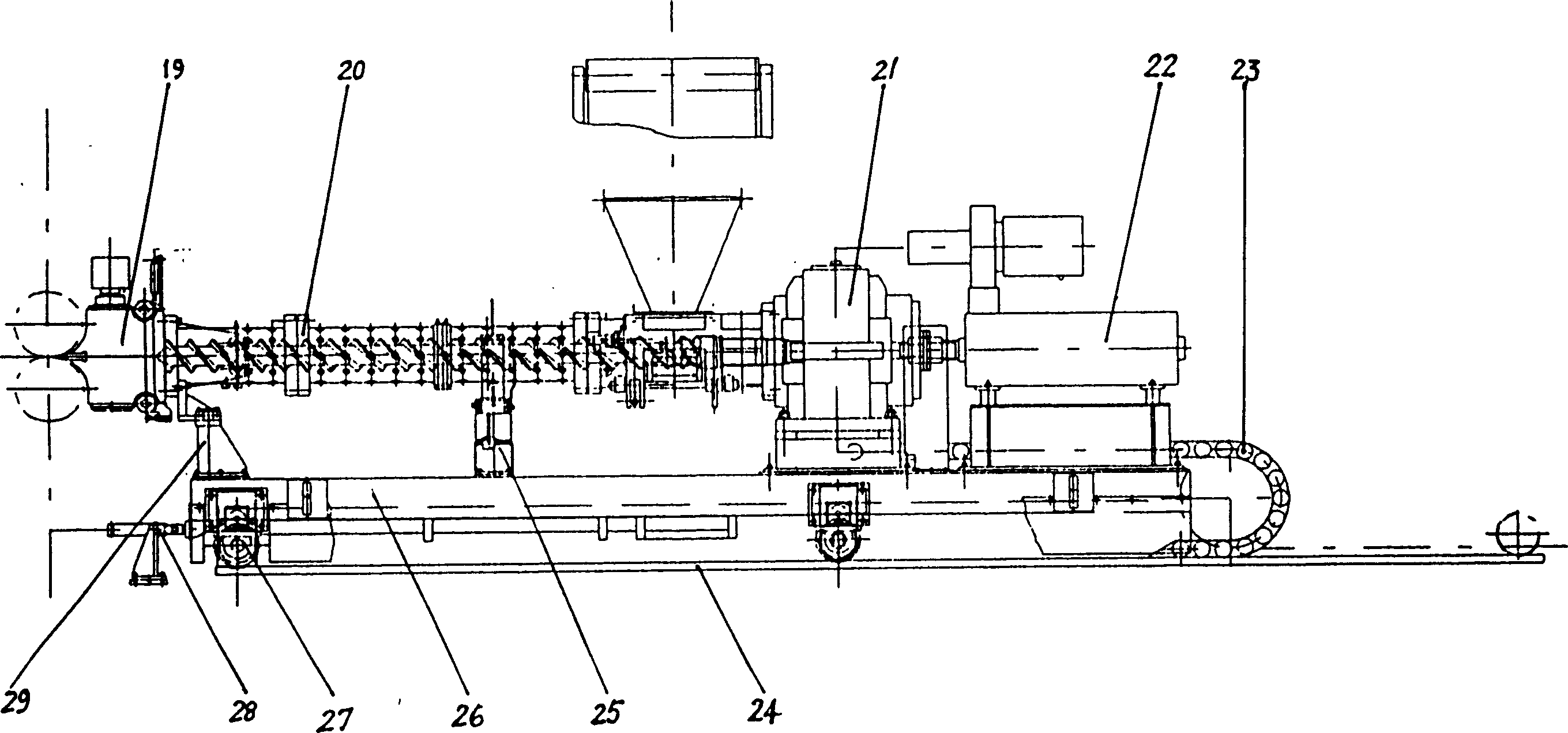

[0021] Embodiment: radial tire inner liner thin film automatic production linkage unit (see figure 1.2), it is characterized in that it is made up of cold feeding extruder mechanism 1, feeding rack mechanism 2, extruder temperature control mechanism 3, roller Cylinder calender mechanism 4, receiving roller mechanism 5, calender temperature control mechanism 6, receiving conveyor belt mechanism 7, film cooling mechanism 8, conveyor belt group frame 9, conveyor belt group mechanism 10, cord opening mechanism I 11. Curtain guide mechanism II 11a, compound coiling conveyor belt mechanism 12, passive coiling mechanism 13, length measuring and cutting conveyor belt mechanism 14, coiling conveyor belt group frame 15, coiling conveyor belt group mechanism 16, coiling Mechanism I 17, coiling mechanism II 17a and electrical control system 18 are formed. The output ends of the above-mentioned mechanisms are sequentially connected to the input ends of the following mechanisms, and each mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com