Ceramic lining composite copper tube production method

A technology of ceramic lining and manufacturing method, which is applied in the field of ceramic lining composite copper pipe manufacturing, can solve the problems that the tube billet crystallizer cannot be processed, the electroplating production pollutes the environment, and the thickness of the chrome plating layer is thin, so as to achieve environmental protection, High production efficiency and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

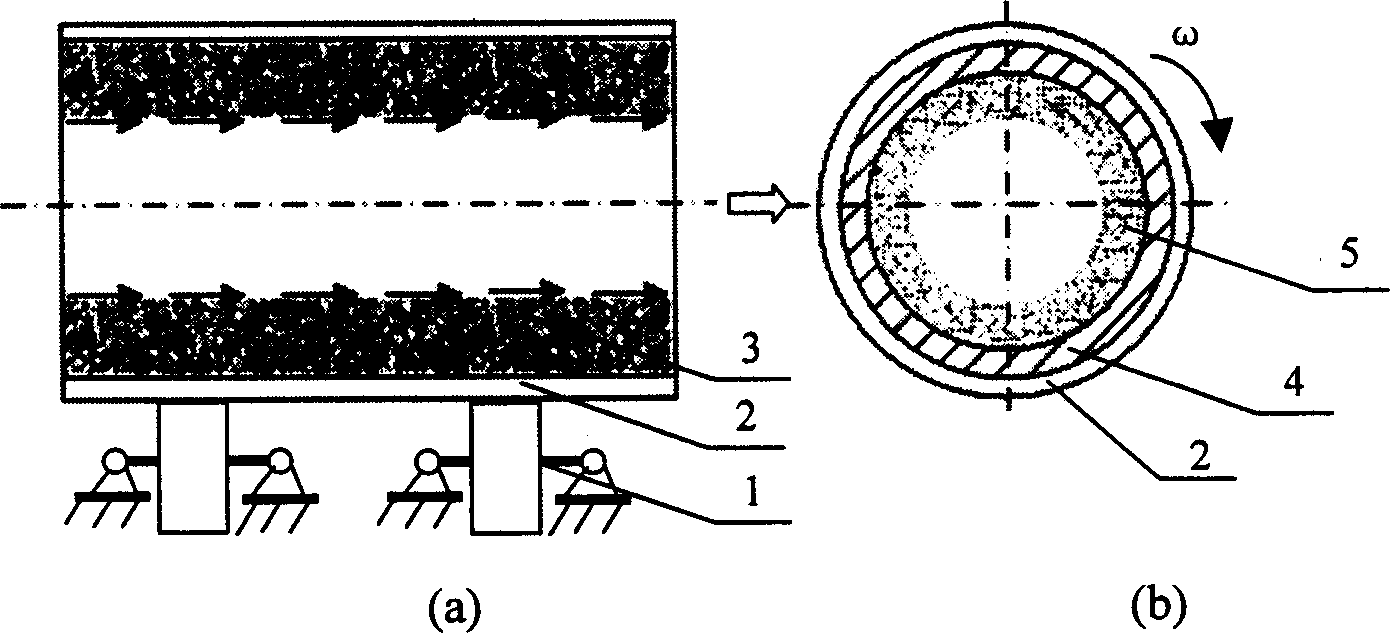

[0052] The thermite 3 is placed in a copper tube 2 with an inner diameter of 150 mm and a length of 1000 mm. In the thermite, CuO powder 120 mesh, aluminum powder 150 mesh, CuO and Al are proportioned at 60% and 30% respectively, and 2.5% of the total material is added with SiO 2 、CrO which accounts for 2% of the total material 3 、Na which accounts for 2.5% of the total material 2 B 4 O 7 、ZrO which accounts for 3% of the total material 2 , After mixing, put it into the copper tube, the copper tube with the material is clamped on the centrifuge 1, and after the centrifuge rotation reaches 1220 rpm, the material is ignited, and Al and CuO react in formula (1). Combustion reaction product Al 2 O 3 It stratifies with Cu under the action of centrifugal force, the combustion reaction lasts for 12 seconds, and stops after 15 minutes to obtain Al-containing 2 O 3 The performance of the ceramic-lined composite copper tube of ceramic 5 and transition layer Cu4 is shown in Table 2. Example ...

Embodiment 2

[0053] The thermite 3 is placed in a copper tube 2 with an inner diameter of 120 mm and a length of 800 mm. In the thermite, CuO powder 150 meshes, aluminum powder 150 meshes, CuO and Al are proportioned at 52% and 32.5% respectively, and 4% of the total material is added with SiO 2 , CrO accounted for 4% of the total material 3 、Na which accounts for 2.5% of the total material 2 B 4 O 7 、ZrO which accounts for 5% of the total material 2 , After mixing, put it into the copper tube, the copper tube containing the material is clamped on the centrifuge 1, and after the centrifuge revolution reaches 1350 rpm, the material is ignited, and Al and CuO react in formula (1). Combustion reaction product Al 2 O 3 And Cu are stratified under the action of centrifugal force, the combustion reaction lasts for 11 seconds, and the machine stops after 14 minutes. 2 O 3 The performance of the ceramic lining composite copper tube of ceramic 5 and transition layer Cu4 is shown in Table 3.

[0054] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com