Micron spherical body composed of nano composite calcium carbonate and its preparation method

A nano-calcium carbonate and nano-composite technology, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve problems such as unevenness, irregularity, and easy aggregation, and achieve good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

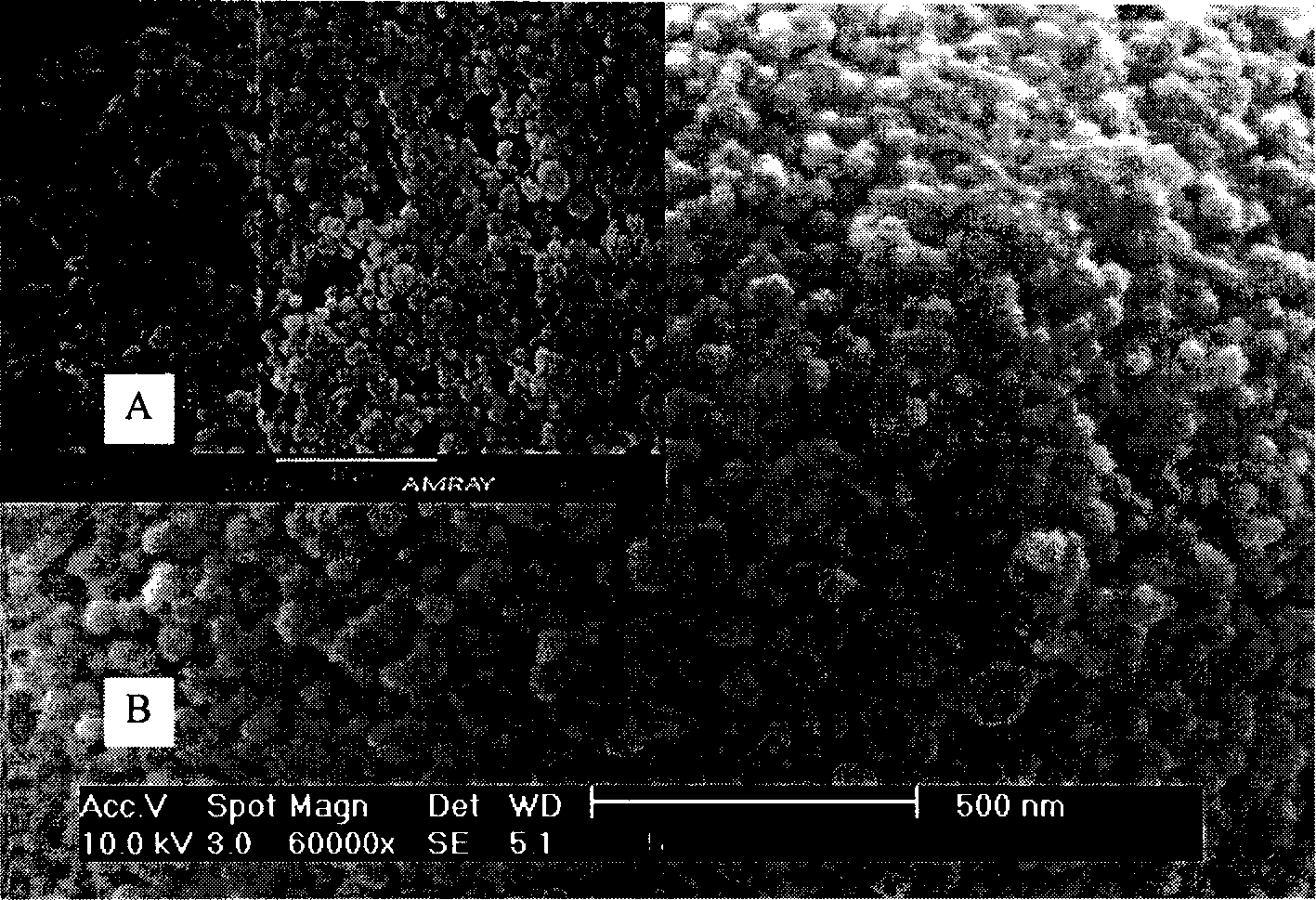

Embodiment 1

[0025] 1) (Liquid A) styrene-acrylic acid copolymer and Na 2 CO 3 The configuration of the mixed solution (the weight of styrene-acrylic acid copolymer is about 5%, the physical index: the weight average molecular weight is 29600, the relative molar ratio of styrene and acrylic acid is 1.05, and the acid value is 308mgKOH / g; CO 3 2- 10% by weight): In 900 mL of deionized water, add 50 g of styrene-acrylic acid copolymer and 172 g of Na 2 CO 3 Solid, stir and heat to 80-90°C and keep stirring until completely dissolved, then cool to 5°C.

[0026] 2) (B solution) CaCl 2 Solution configuration (about 5mol / L), 140g anhydrous CaCl 2 Add 250mL of deionized water and stir to dissolve it all.

[0027] 3) Preparation of micron spherical nanocomposite calcium carbonate: Pour liquid B continuously and slowly into liquid A which is being stirred, the temperature is controlled at 5°C, the time for adding liquid B is about 10 minutes, and continue to stir and react after adding liquid...

Embodiment 2

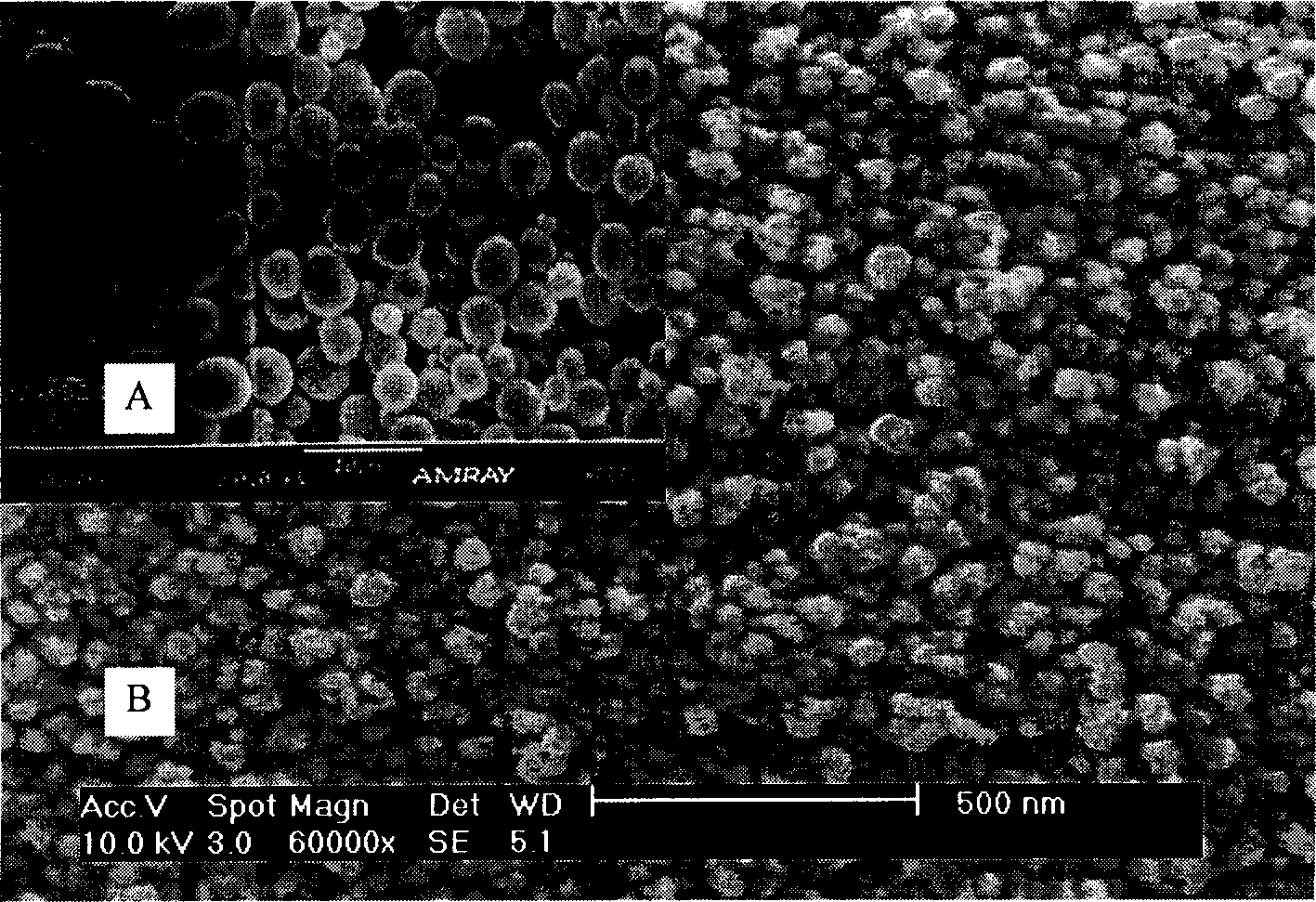

[0029] 1) (Liquid A) styrene-acrylic acid copolymer and Na 2CO 3 The configuration of the mixed solution (the weight of styrene-acrylic acid copolymer is about 2.0%, the physical index: the weight average molecular weight is 21300, the relative molar ratio of styrene and acrylic acid is 1.85, and the acid value is 210mgKOH / g; CO 3 2- The weight is about 0.8%): Add 20g of styrene-acrylic acid copolymer to 400mL deionized water and adjust the pH value to 8-10 with NaOH, stir and heat to 70-80°C and keep stirring until completely dissolved, then dissolve in 500mL deionized water Add 11g NaHCO 3 The solid was stirred and dissolved, and the above two solutions were combined, stirred evenly and cooled to 30°C.

[0030] 2) (B solution) CaCl 2 Solution configuration (about 1.35mol / L), 15g anhydrous CaCl 2 Add 100mL of deionized water and stir to completely dissolve.

[0031] 3) Preparation of micron spherical nanocomposite calcium carbonate: Pour liquid B continuously and slowly...

Embodiment 3

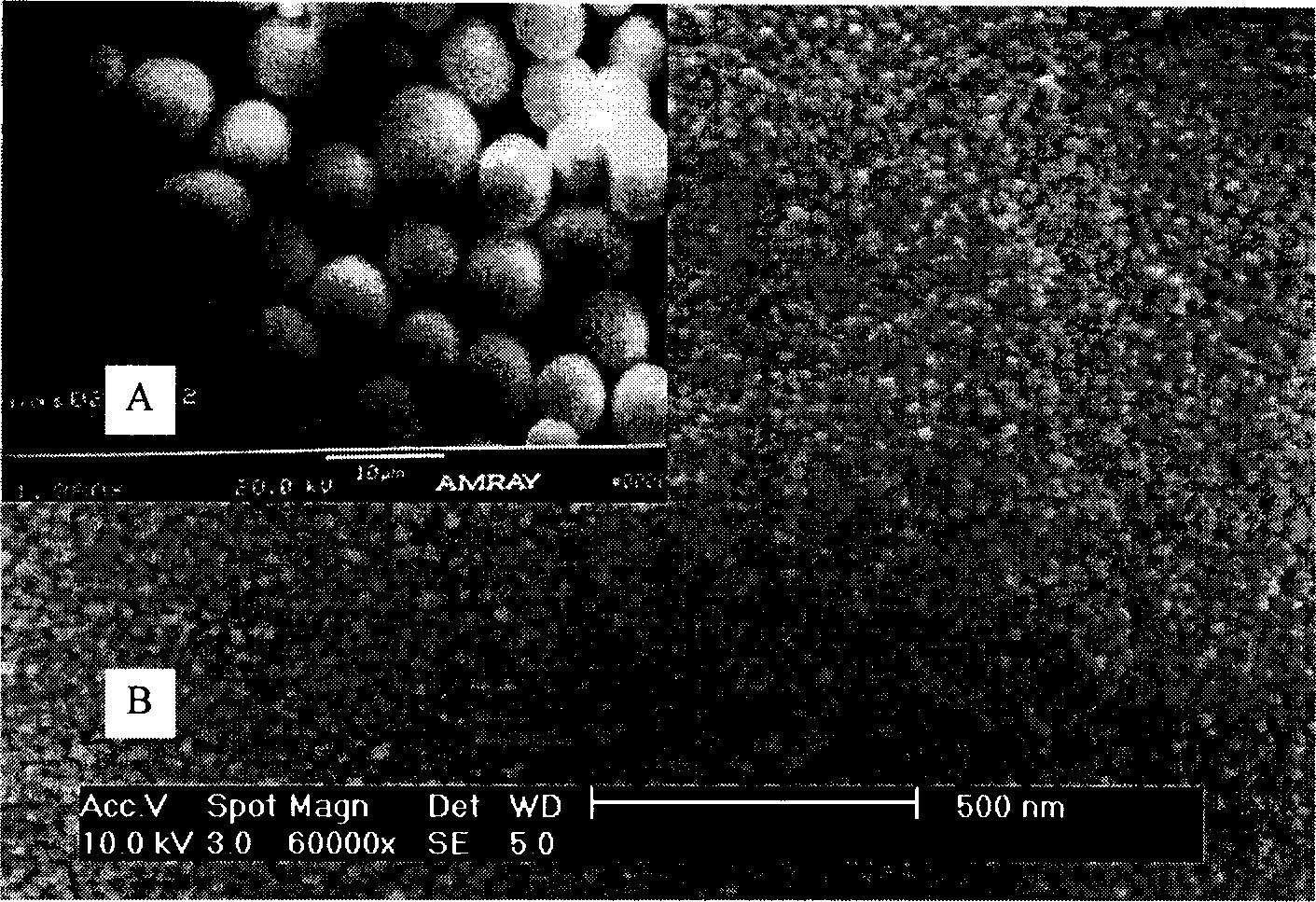

[0033] 1) (Liquid A) styrene-acrylic acid copolymer and Na 2 CO 3 The configuration of the mixed solution (the weight of styrene-acrylic acid copolymer is about 0.5%, the physical index: the weight average molecular weight is 14300, the relative molar ratio of styrene and acrylic acid is 2.45, and the acid value is 170mgKOH / g; CO 3 2- The weight is about 1.2%): In 900mL deionized water, add 5.0g styrene-acrylic acid copolymer and 19g (NH 4 ) 2 CO 3 Solid, stir and heat to 60-70°C and keep stirring until completely dissolved, then cool to 40°C

[0034] 2) (B solution) CaCl 2 Solution configuration (about 2mol / L), 24g anhydrous CaCl 2 Add 110mL of deionized water, stir to dissolve all.

[0035] 3) Preparation of micron spherical nanocomposite calcium carbonate: continuously and slowly pour liquid B into stirred liquid A, control the temperature at 40°C, add liquid B for about 20 minutes, and continue to stir and react after adding liquid B After 30 minutes, a white emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com