Prepn process of nano ecological oxychloride sterilizer

The technology of a chlorine-oxygen disinfectant and a production method is applied in the field of production of nano-type ecological chlorine-oxygen disinfectants, which can solve the problems affecting popularization and application, poor product purity, and backward technology, and achieve broad market prospects and low production and use costs. , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] (1) Preparation of organic fungicides:

[0020] 1. The formula and content range (percentage by weight) of the organic fungicide:

[0021] Polysaccharide: 10%~15%

[0022] Garlic: 25% to 35%

[0023] Triangle pepper: 15% to 25%

[0024] Process water: 50%

[0025] 2. Process flow:

[0026] Soak the polysaccharide in 25°C-30°C process water for 3-5 hours to obtain a 3% polysaccharide solution for use, peel and wash the garlic, and remove impurities from the fresh pepper by 1:3-5 times the process water Use a homogenizer to make a micro slurry to liquefy, get 12% garlic solution and 8% pepper solution, grind and filter, then emulsify to ultra-micron 15-30nm, in a liquefied state, then mix with polysaccharides and add to the polymerization kettle, and continue to stir After 3 hours, after filtering and removing impurities, put it into the finished product tank and pack it to become an organic fungicide.

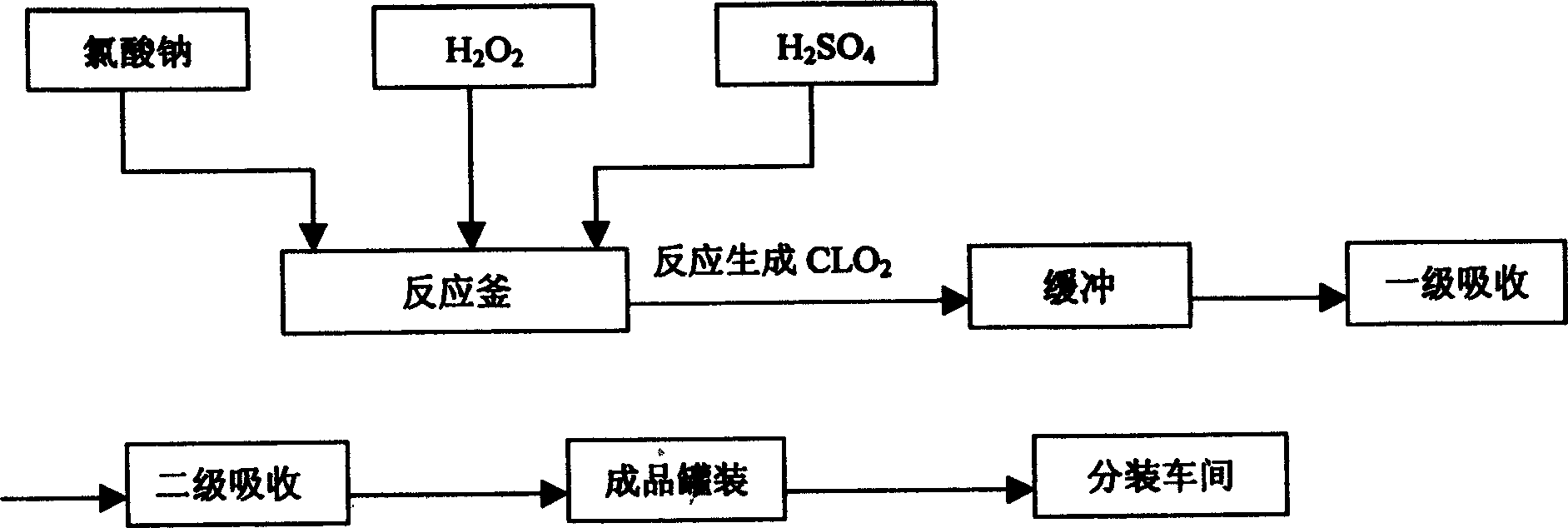

[0027] (2) Preparation of Chlorine Dioxide

[0028] 1. The ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com