Synthesis method of nickel-aluminum hydrotalcite nanomaterials

A technology of nickel-aluminum hydrotalcite and nanomaterials, applied in the direction of nanotechnology, nickel compounds, nanotechnology, etc., can solve the problems of unstable capacitor structure, too fast weakening of cycle life, etc., achieve excellent electrochemical characteristics, overcome agglomeration phenomenon and Overlap phenomenon, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The synthesis method of nickel-aluminum hydrotalcite nanomaterials, the preparation steps are as follows:

[0030] 1) Take nickel nitrate solution, add aluminum nitrate nonahydrate solid material and stir well;

[0031] 2) Add sodium polystyrene sulfonate solution or starch solution into the above mixed solution and stir evenly;

[0032] 3) Add urea to the above mixed solution and stir evenly;

[0033] 4) Transfer the above liquid to a container for sealed storage;

[0034] 5) Carry out heating reaction at 60-240 degrees Celsius, and the reaction time is 1-48h;

[0035] 6) Take the sediment for filtration washing or centrifugal washing;

[0036] 7) After drying at 20-80 degrees Celsius for 1-24 hours, a flower-shaped three-dimensional nickel-aluminum hydrotalcite nanomaterial composed of two-dimensional nanosheets is prepared.

[0037] Step 1) The Ni 2+ The molar mass of Al is 3+ 2-5 times of that, wherein the concentration of nickel nitrate is 0.1-3mol / L. The mo...

Embodiment 1

[0039] 1) Measure 2-100ml of 0.1-3mol / L nickel nitrate solution, add 10-500mg of aluminum nitrate nonahydrate solid material and stir well;

[0040] 2) Measure 0.1-50g / L polystyrene sodium sulfonate (PSS) solution or 5-100ml starch solution into the above mixed solution and stir evenly;

[0041] 3) Weigh 1-100mmol of urea and add it to the above mixed solution and stir evenly;

[0042] 4) Transfer the above liquid to the reactor;

[0043] 5) Carry out hydrothermal reaction at 60-240 degrees Celsius, and the reaction time is 1-24h.

[0044] 6) Take the precipitate for filtration washing or centrifugation washing several times.

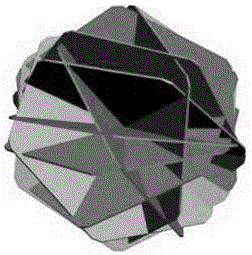

[0045] 7) Dry at 20-80 degrees Celsius for 24 hours, that is, the figure 1 The flower-shaped NiAl hydrotalcite nanomaterials are shown.

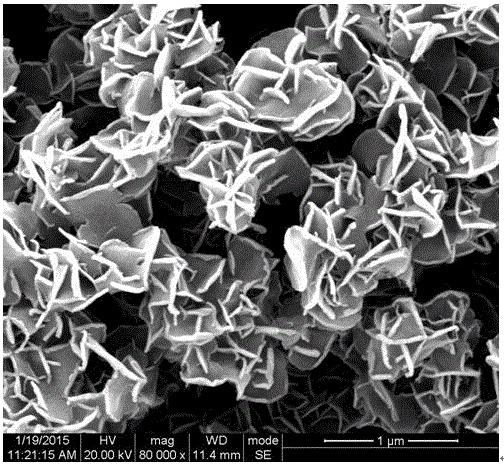

[0046] The characterization results of the nickel-aluminum hydrotalcite nanomaterials prepared in this example are as follows figure 2 As shown, it is indicated that nickel aluminum hydrotalcite is a micron-scal...

Embodiment 2

[0048] 1) Measure 10ml of 0.1mol / L nickel nitrate solution, add 10mg of aluminum nitrate nonahydrate solid material and stir well;

[0049] 2) Measure 20ml of 0.1g / L polystyrene sodium sulfonate (PSS) solution and add it to the above mixed solution and stir evenly;

[0050] 3) Weigh 1 mmol of urea and add it to the above mixed solution and stir evenly;

[0051] 4) Transfer the above liquid to the reactor;

[0052] 5) Carry out hydrothermal reaction at 60 degrees Celsius, and the reaction time is 24h;

[0053] 6) Take the precipitate and carry out filtration washing or centrifugal washing several times;

[0054] 7) Dry at 60 degrees Celsius for 24 hours, that is, the figure 1 Schematic flower-shaped nickel-aluminum hydrotalcite nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com