Preparation method of heat-conductive plastic adopting ordered space network structure

A technology of network structure and heat-conducting plastics, which is applied in the deep processing and application of polymer composite materials, can solve the problems that the heat-conducting network has no orientation and cannot fully exert its function, and achieve the effects of low filling, improved product performance, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First, mix graphene with a mass fraction of 5%, processing aids, and polyethylene (PE) particles with a high-speed mixer for 5 minutes; then put 1200 g of the mixed particles into the SCS micro-nano particle shaping and coating system, at a speed of 3000 rpm Processing for 10 minutes, discharging for 5 minutes. Finally, after hot-pressing the composite particles at 210°C and a pressure of 14 MPa for 30 minutes, a heat-conducting plastic with an ordered spatial heat-conducting network structure was obtained.

Embodiment 2

[0023] First, mix nano-alumina, processing aids and polyethylene (PE) particles with a mass fraction of 5% with a high-speed mixer for 5 minutes; then put 1200g of the mixed particles into the SCS micro-nano particle shaping and coating system, at a speed of 3000rpm Down processing 10min, discharge 5min. Finally, after hot-pressing the composite particles at 210°C and a pressure of 14 MPa for 30 minutes, a heat-conducting plastic with an ordered spatial heat-conducting network structure was obtained.

Embodiment 3

[0025] First, mix nano-copper powder with a mass fraction of 5%, processing aids, and polyethylene (PE) particles with a high-speed mixer for 5 minutes; then put 1200g of the mixed particles into the SCS micro-nano particle shaping and coating system, at a speed of 3000rpm Processing for 10 minutes, discharging for 5 minutes. Finally, after hot-pressing the composite particles at 210°C and a pressure of 14 MPa for 30 minutes, a heat-conducting plastic with an ordered spatial heat-conducting network structure was obtained.

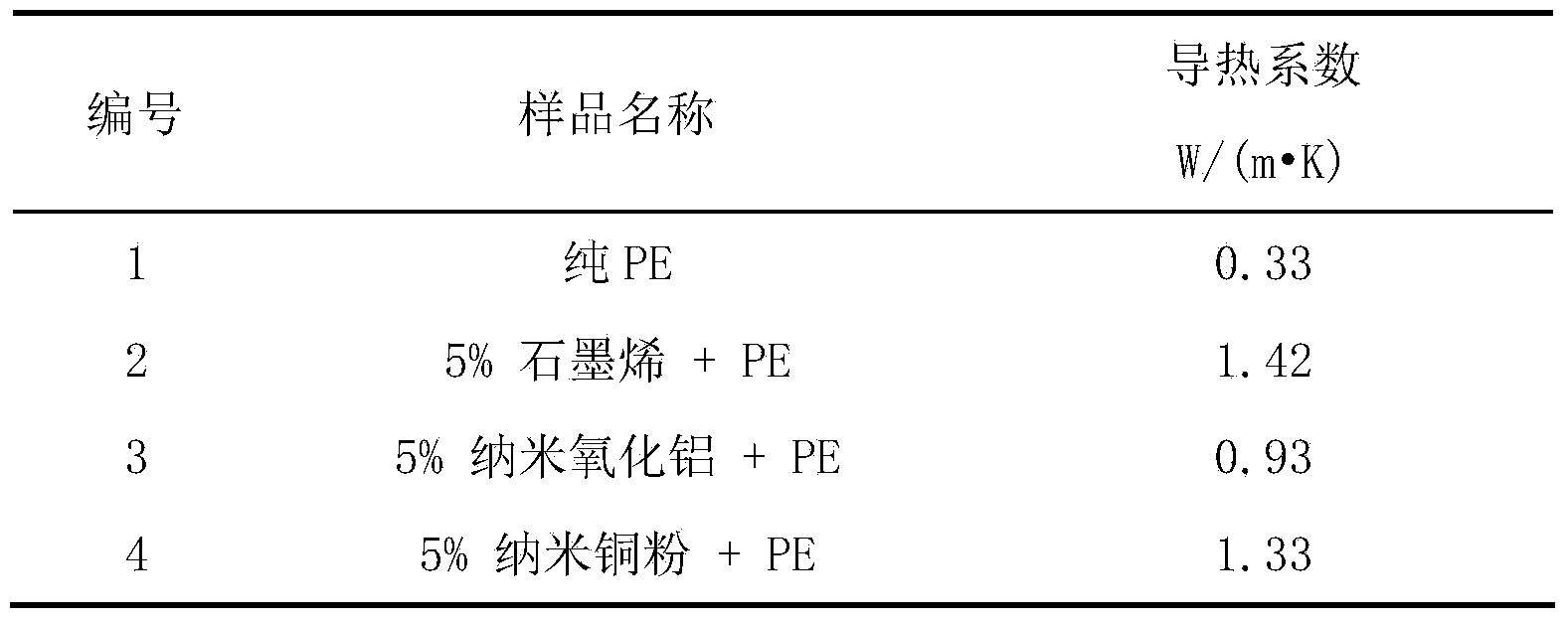

[0026] The thermal conductivity of thermally conductive plastics with an ordered space thermally conductive network structure prepared by the above three methods is shown in Table 1:

[0027] Table.1 Table of thermal conductivity of thermally conductive plastics prepared with different thermally conductive fillers

[0028]

[0029] It can be seen from the above table that under the same conditions, the thermal conductivity of the thermally conductive pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com