Femtosecond laser surface pretreatment method for improving bonding state of layer base or film base

A technology of surface pretreatment and femtosecond laser, which is applied in the field of femtosecond laser technology application, can solve problems that do not involve femtosecond laser pretreatment methods, etc., and achieve the effect of improving the bonding state, increasing the bonding strength, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

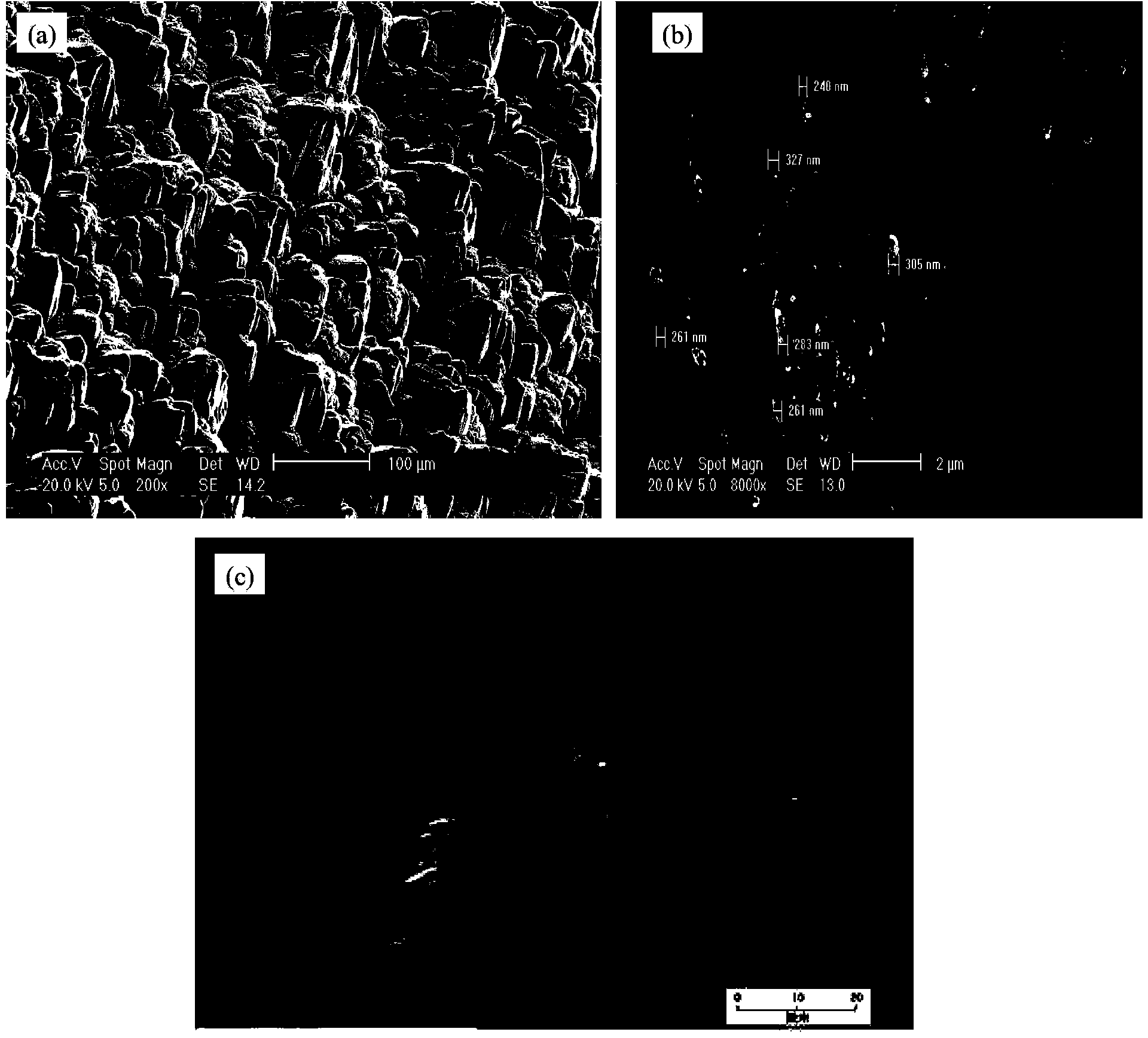

[0032] The 4340 steel directly deposited by the laser is preliminarily polished with sandpaper; the femtosecond laser is turned on to pretreat the surface of the 4340 steel. The specific process parameters are as follows: the laser repetition frequency is 1000 kHz, the pulse energy is 8 μJ, the scanning speed is 480 mm / s, and the number of repeated scanning is 120 times.

[0033] Then without any other pretreatment, the electroless Ni-P plating experiment was carried out on the 4340 steel pretreated by femtosecond laser. After metallographic sample preparation, observe the combination of the cross section after pretreatment and electroless plating, such as figure 2 shown. For the convenience of comparison, the untreated 4340 steel was electroless plated as a comparison sample, and the combination of the cross section is shown in figure 1 . It can be seen that the combination of the untreated 4340 steel electroless coating and the substrate is discontinuous, and some areas ...

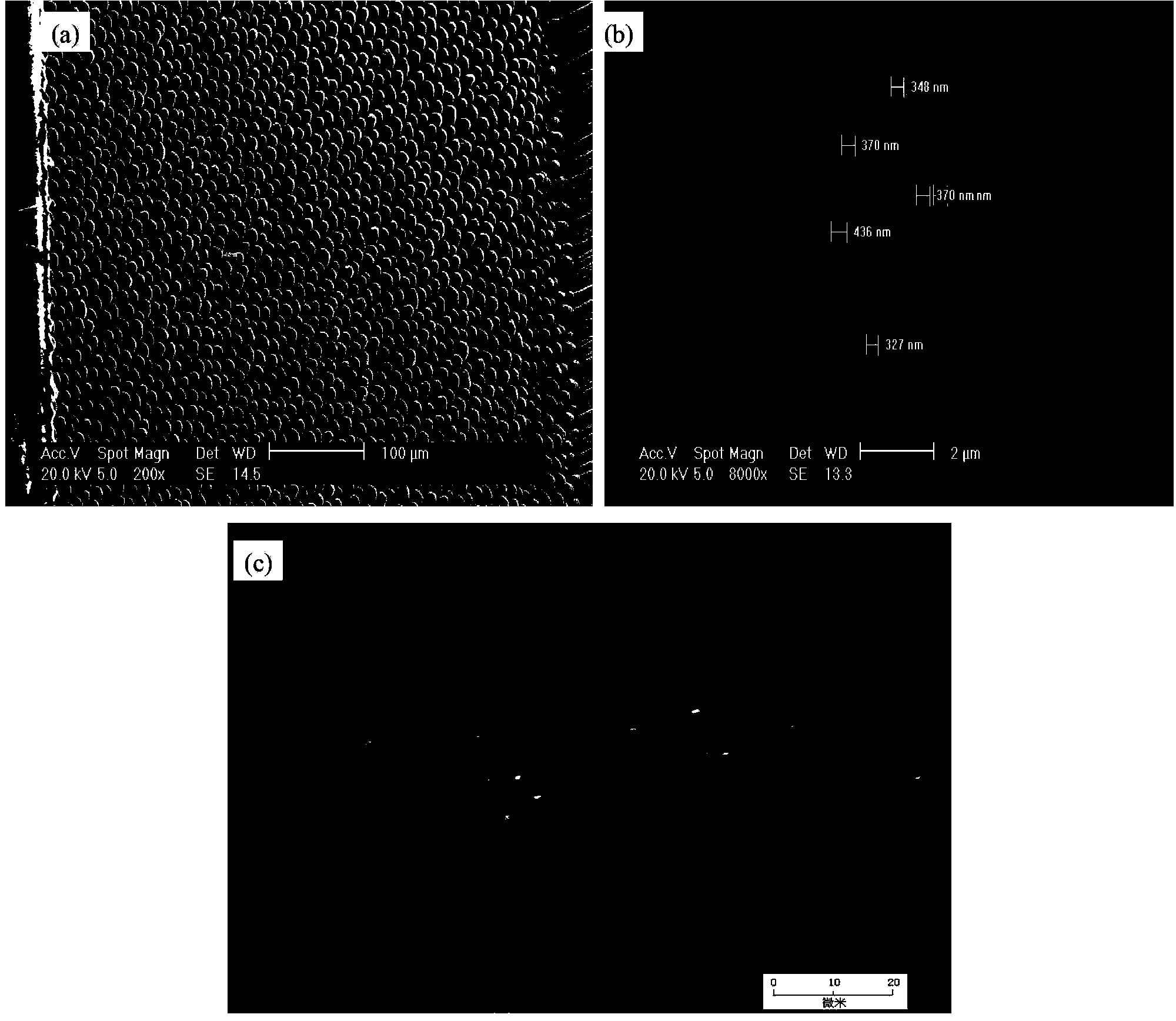

Embodiment 2

[0035] The 4340 steel directly deposited by the laser is preliminarily polished with sandpaper; the femtosecond laser is turned on to pretreat the surface of the 4340 steel. The specific process parameters are as follows: the laser repetition frequency is 1000 kHz, the pulse energy is 8 μJ, the scanning speed is 1200 mm / s, and the number of repeated scanning is 300 times.

[0036] Then without any other pretreatment, the electroless Ni-P plating experiment was carried out on the 4340 steel pretreated by femtosecond laser. After metallographic sample preparation, observe the combination of the cross section after pretreatment and electroless plating, such as image 3 shown. For the convenience of comparison, the untreated 4340 steel was electroless plated as a comparison sample, and the combination of the cross section is shown in figure 1 . It can be seen that the combination of the untreated 4340 steel electroless coating and the substrate is discontinuous, and some areas ...

Embodiment 3

[0038] The 4340 steel directly deposited by the laser is preliminarily polished with sandpaper; the femtosecond laser is turned on to pretreat the surface of the 4340 steel. The specific process parameters are as follows: the laser repetition frequency is 500 kHz, the pulse energy is 2 μJ, the scanning speed is 120 mm / s, and the number of repeated scanning is 180 times.

[0039]Then without any other pretreatment, the electroless Ni-P plating experiment was carried out on the 4340 steel pretreated by femtosecond laser. After metallographic sample preparation, observe the combination of the cross section after pretreatment and electroless plating, such as Figure 4 shown. For the convenience of comparison, the untreated 4340 steel was electroless plated as a comparison sample, and the combination of the cross section is shown in figure 1 . It can be seen that the combination of the untreated 4340 steel electroless coating and the substrate is discontinuous, and some areas ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com