Mixing method for heterogeneous reaction and super strong turbulent mass transfer tower

A multiphase reaction and mass transfer tower technology, applied in the field of super turbulent mass transfer towers, can solve the problems of turbulent flow intensity attenuation, etc., and achieve the effects of reduced mass transfer space, low energy consumption, and optimized energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

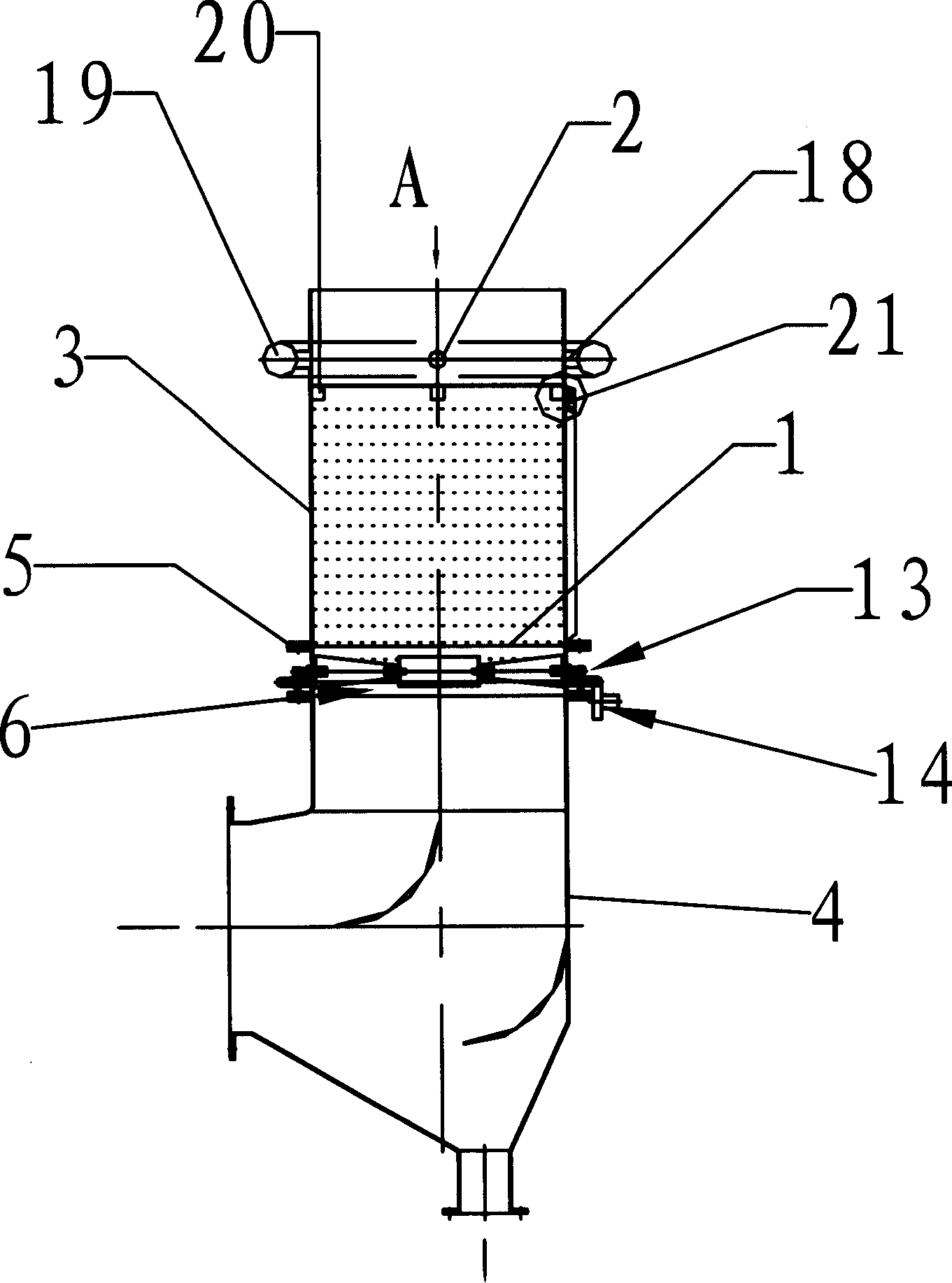

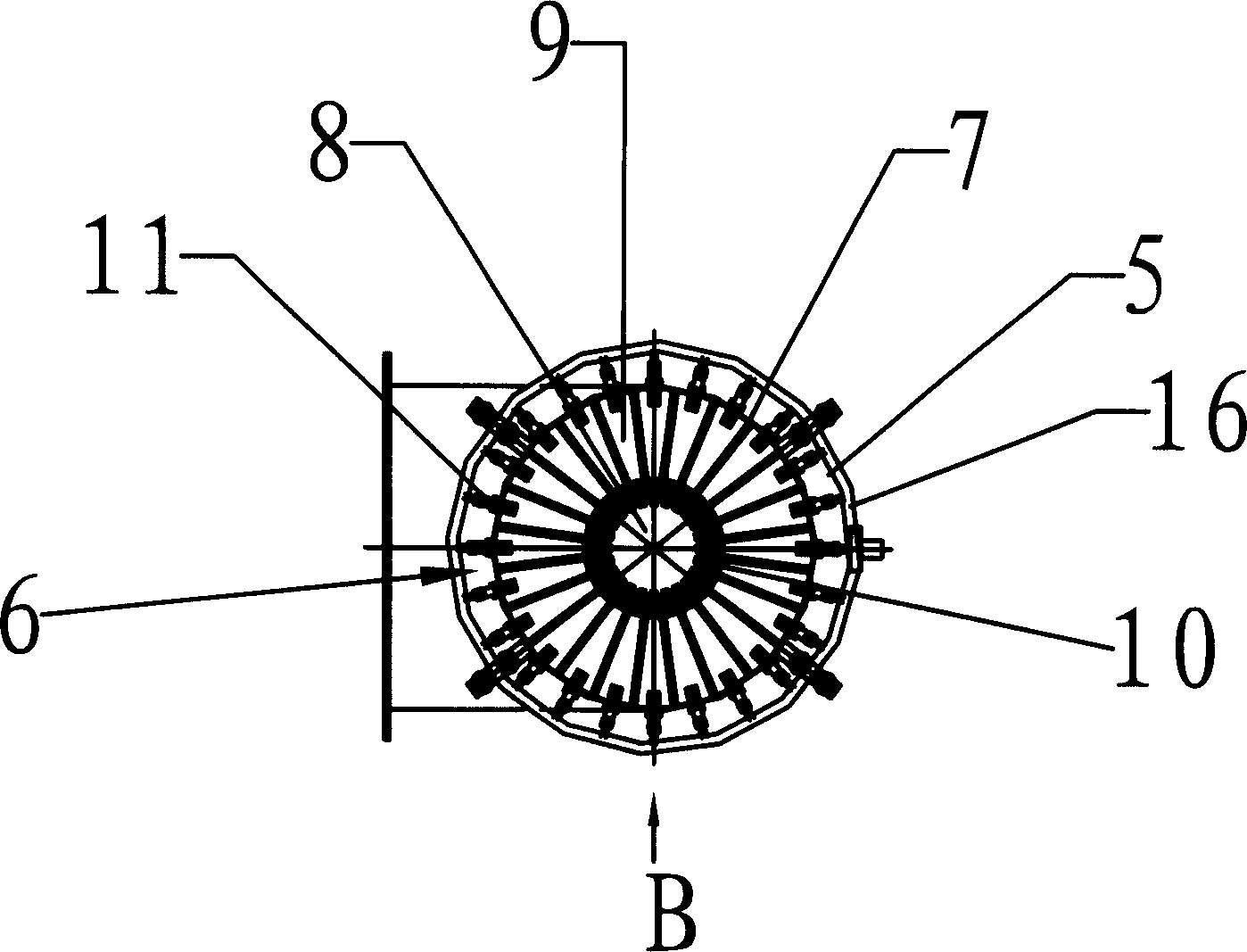

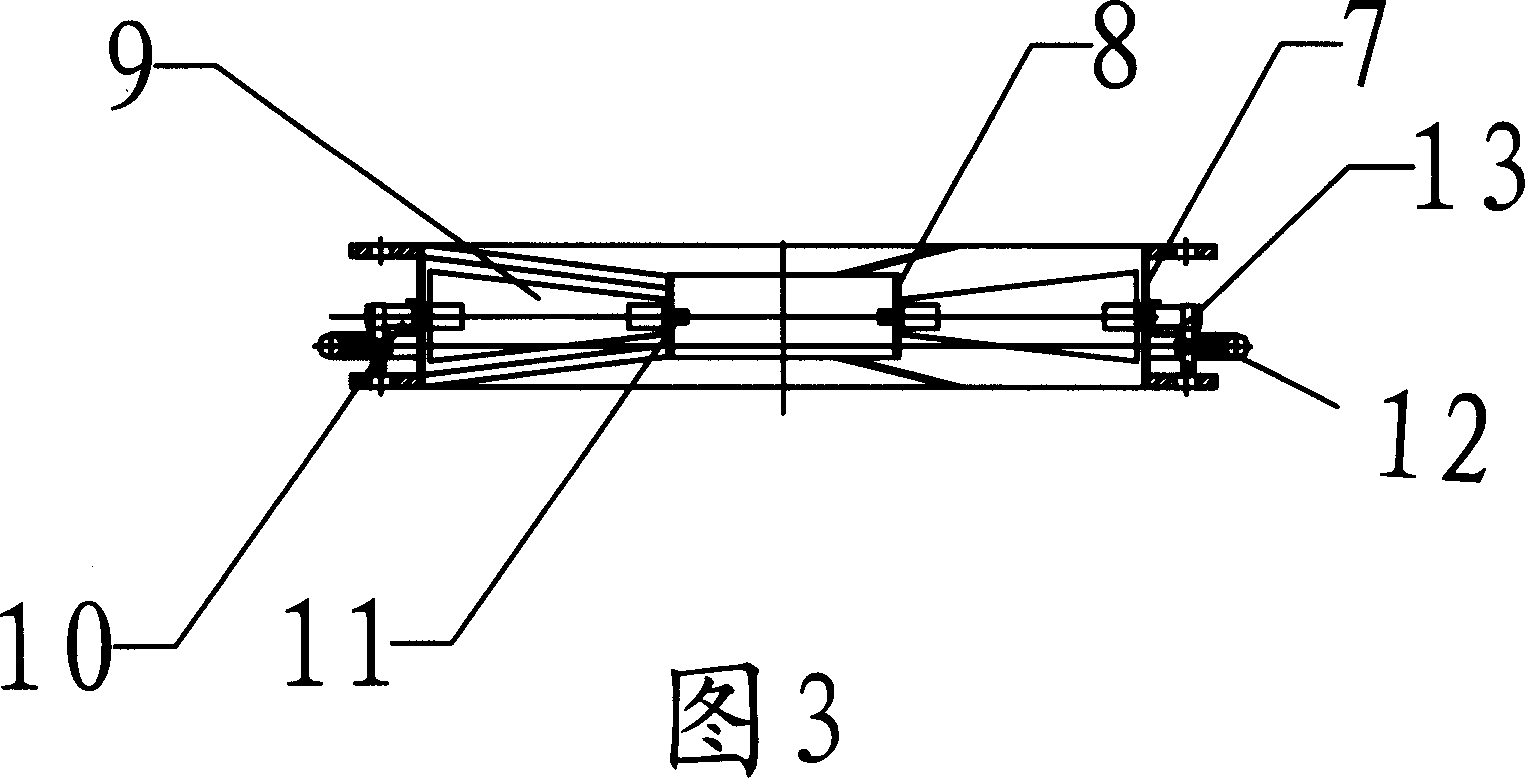

[0026] figure 1 with figure 2A preferred embodiment of the invention is shown. Wherein the super-turbulent mass transfer tower of the present invention comprises a mass transfer tower body 3 provided with an air inlet 1 and a liquid inlet 2, an arc-shaped duct 4 communicated with the air inlet 1; The liquid input pipe connected to the liquid inlet 2. Wherein the flow guide pipe 4 and the air inlet 1 of the mass transfer tower are connected together through a diversion pipe 5, and the diversion pipe 5 is provided with a plurality of adjacent and circumferentially distributed cross-sections approximately A mechanism 6 for accelerating and diffusing the airflow composed of trapezoidal small flow tubes. Referring to Fig. 3 , the specific structure of the diverter tube 5 includes an outer wall 7 and a central support 8; Trapezoidal upper bottom side wall, with the inner side wall of the outer wall 7 of the diverter tube as the lower bottom wall, and a radially arranged partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com