Frequency-modulated, amplitude-modulated resultant force forming machine

A technology of frequency modulation, amplitude modulation, and molding machines, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., and can solve problems such as inconvenient operation, inability to change the frequency of vibration, and unsightly appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

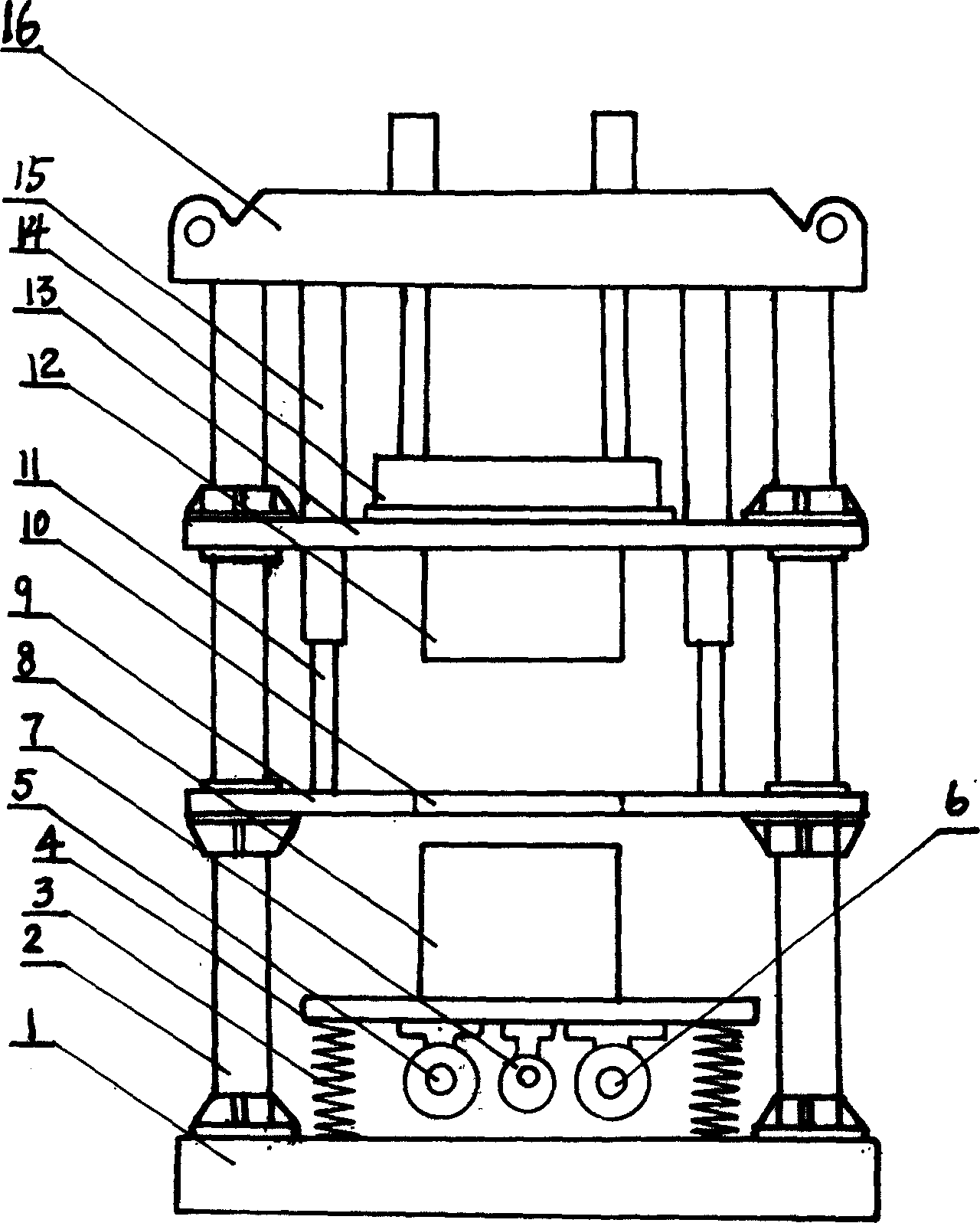

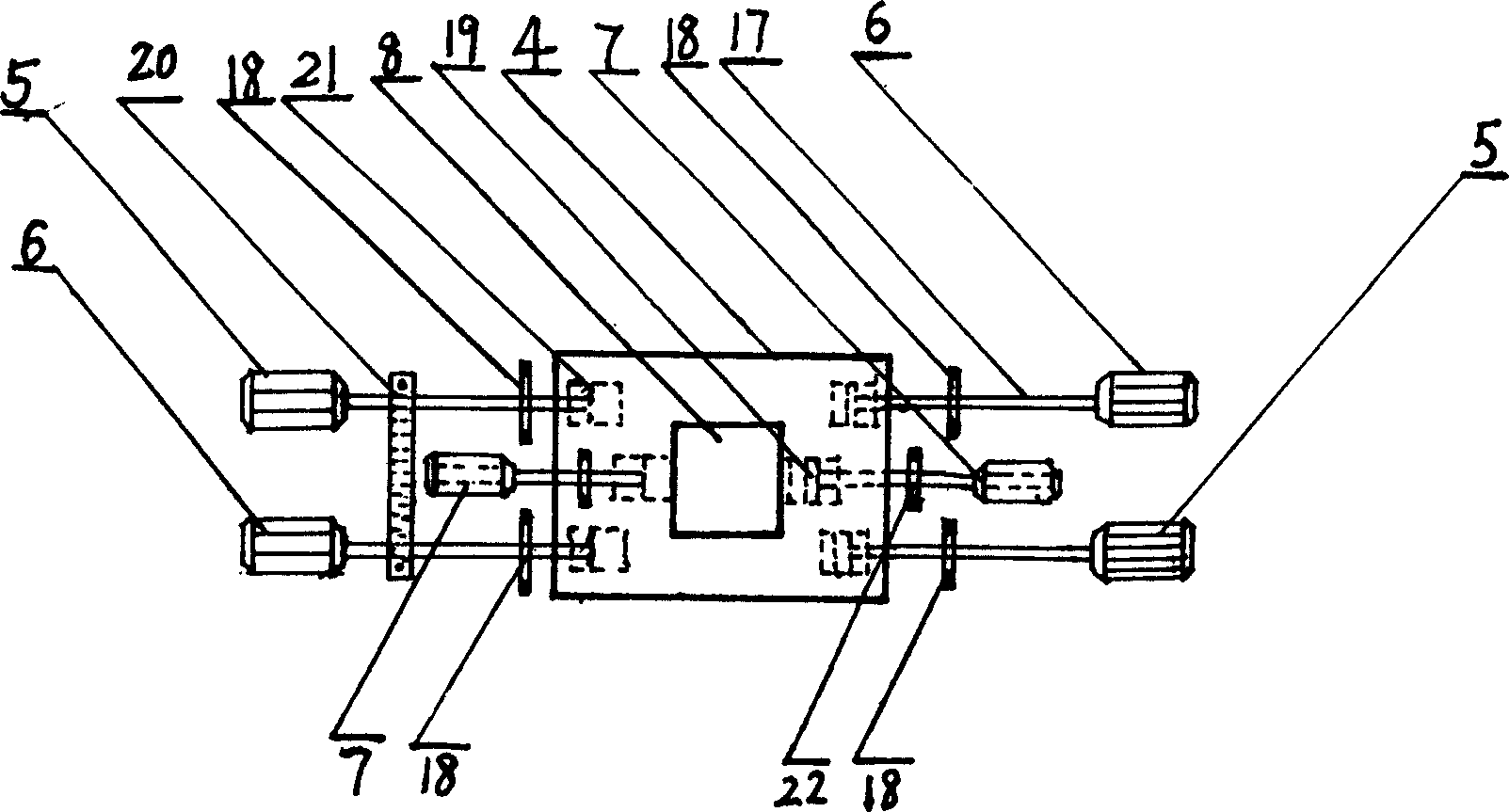

[0018] The frequency and amplitude modulation combined force forming machine described in Example 1 is composed of a hydraulic device, a forming device and a vibration device. The vibration device is composed of a high-frequency vibration excitation device and a frequency converter. The vibration device is fixed on the base (1). A column (2) is placed vertically on the four corners of (1). The upper ends of the columns (2) are respectively fixed on the four corners of the top beam (16). The hydraulic device is fixed on the top through the upper end of the movable mold table (13). The lower end of the beam is fixed on the demolding table (9). The forming device is composed of the movable die table (13), the demolding table (9), the mold frame (24) and the mold. The high-frequency excitation device is mounted on two sets of shafts. It is composed of motors with eccentric wheels, each group has two motors, and the rotation speed is the same and the direction is opposite. The mass of ...

Embodiment 2

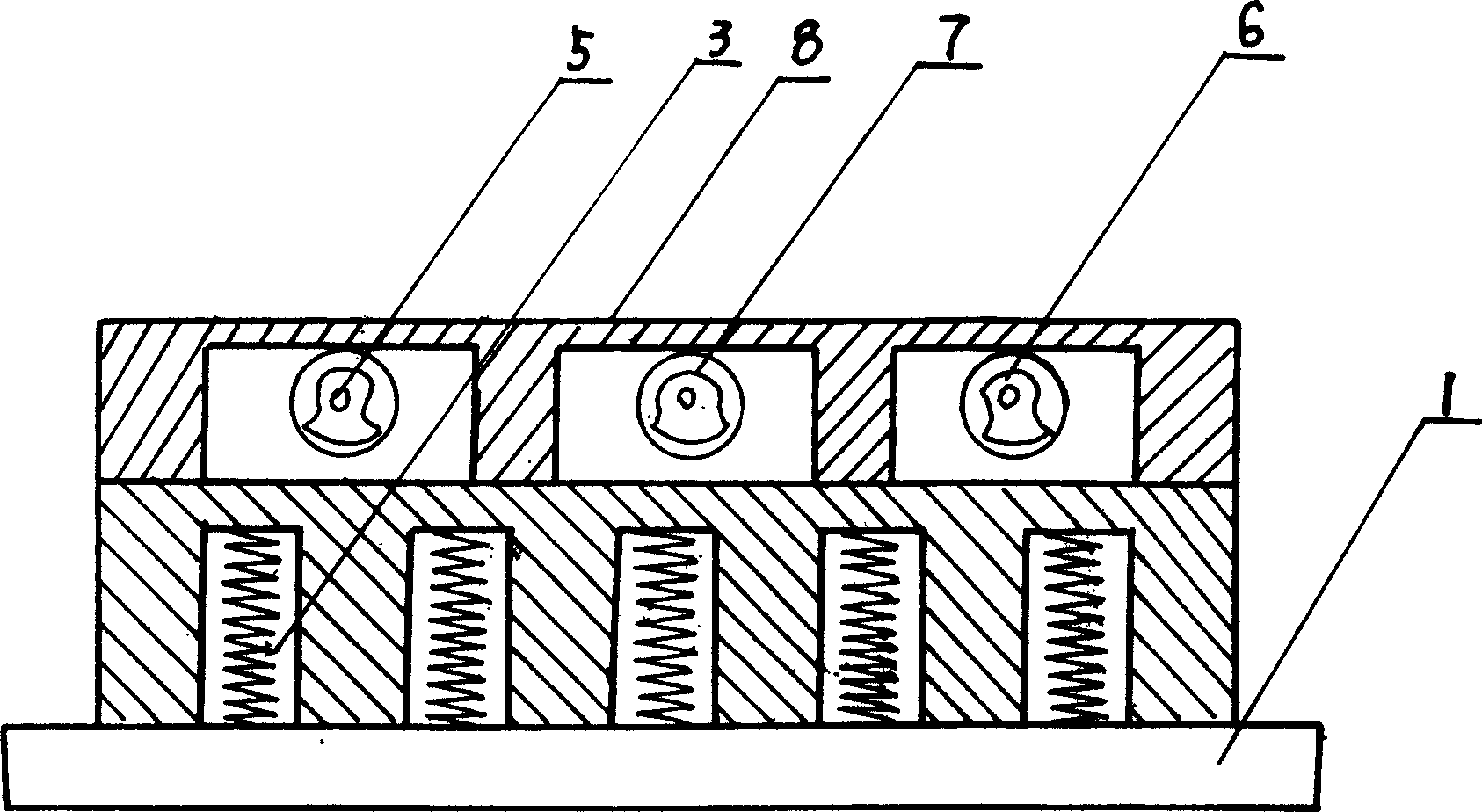

[0019] The guiding vibration column (8) of the frequency and amplitude modulation combined force forming machine described in embodiment 2 is in the shape of a box, and the box is divided into upper and lower layers. The high-frequency excitation device and the frequency converter are installed on the upper layer, and the lower layer is equipped with more than three The lower end of the spring and the vibration guide column (8) is directly connected with the base (1).

Embodiment 3

[0020] The side view of the vibrating table (4) of the frequency and amplitude modulation combined force forming machine described in embodiment 3 is dumbbell-shaped, and the high-frequency excitation device and the frequency converter are respectively installed in the cavities on both sides. The connection between the two cavities The bottom surface is on the upper surface of each cavity, the upper surface of the connecting surface can be placed on the mold frame (24), the lower surface is connected with more than three springs, the lower surface of the cavity and the lower end of the spring are both connected to the base (1) The upper surface is connected.

[0021] The implementation of the present invention has the following advantages:

[0022] The frequency and amplitude modulation combined force forming machine provided by the present invention is composed of a hydraulic device and a vibration device. The vibration device is composed of a high-frequency vibration excitation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com