Method for refining 4-amino diphenylamine

A technology of aminodiphenylamine and aniline, which is applied in the field of refining 4-aminodiphenylamine, and can solve the problems of difficult separation by distillation, waste of resources, and aniline being mechanically returned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

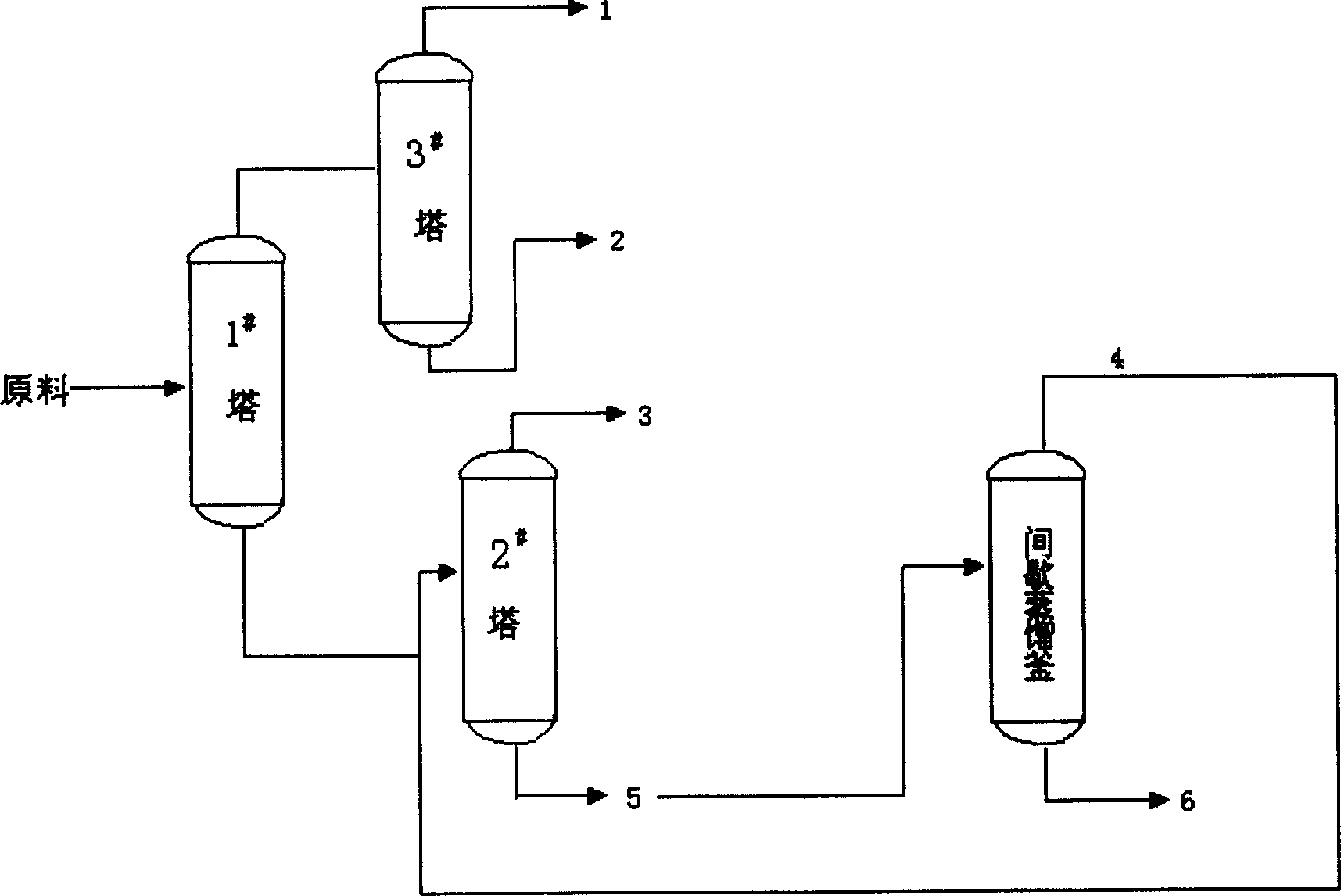

[0015] The crude product containing 4-aminodiphenylamine (containing 4-aminodiphenylamine 78.1%, aniline 20.1%, azobenzene 1.1%, phenazine 0.7%) was continuously fed into No. 1 rectification through a gear pump at a flow rate of 120 kg / hour tower. The temperature of the tower kettle was controlled at 270°C, the temperature at the top of the tower was controlled at 110°C, the degree of vacuum was 0.094MPa, the reflux ratio was 5:1, and three substances, aniline, azobenzene, and phenazine, were extracted from the top of the tower, and the flow rate was 26.2 kg. About / hour, enter No. 3 rectifying tower, No. 3 rectifying tower tower still temperature 150 ℃, tower top temperature 90 ℃, vacuum degree 0.094MPa, reflux ratio 1: 1, tower top distills out aniline with flow rate 24 kg / hour , what is left in the tower still is azobenzene, phenazine, 1 rectifying tower tower still liquid enters No. 2 rectifying tower, keeps tower still temperature 280 ℃, vacuum degree 0.097MPa, tower top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com