Heat measuring apparatus and method thereof

A technology of thermal testing and control devices, applied in the direction of measuring devices, calorimeters, measuring heat, etc., can solve problems such as test verification cannot be carried out, air flow loss in air ducts, single test points, etc., to achieve comprehensive test items and reduce measurement errors , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

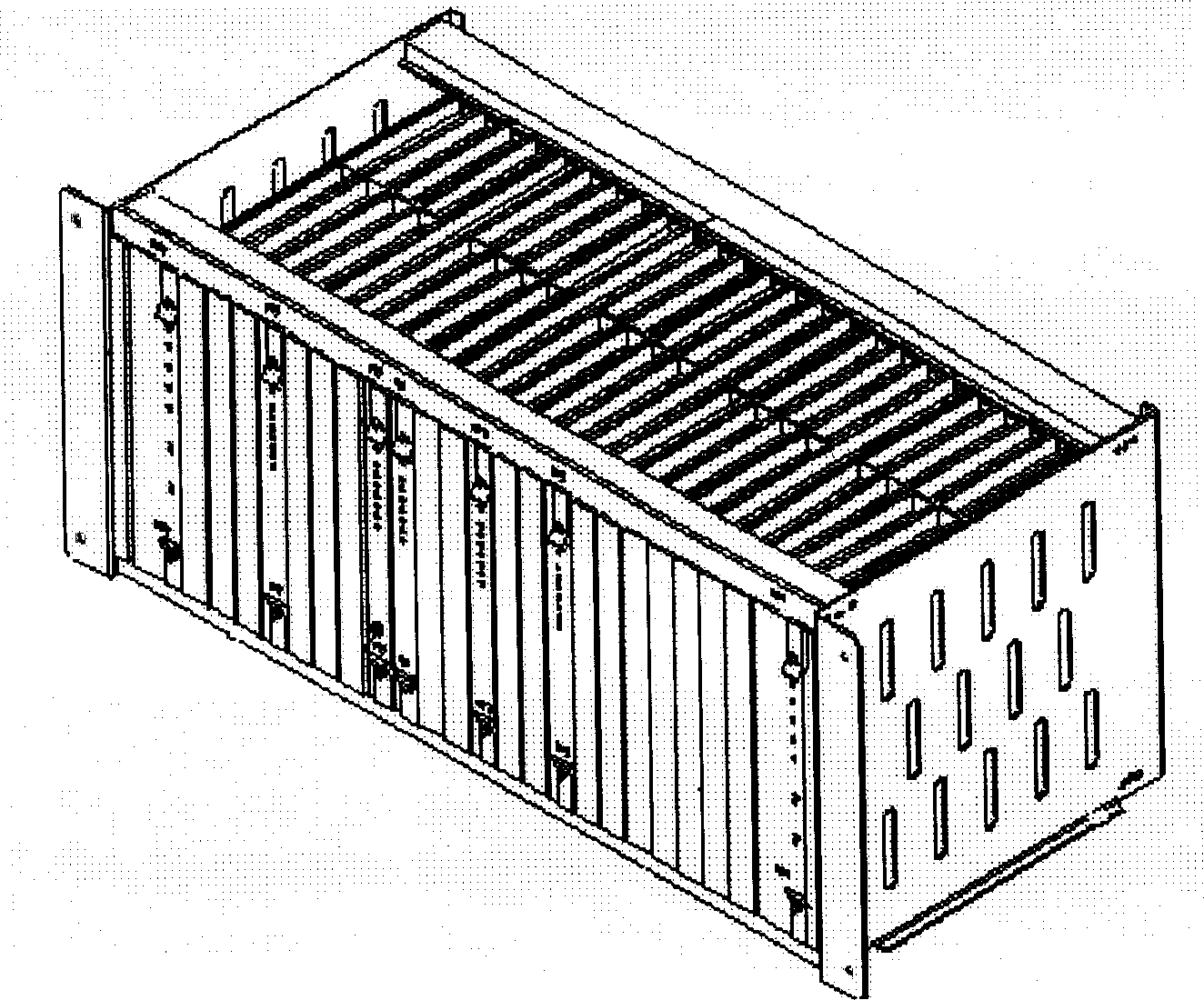

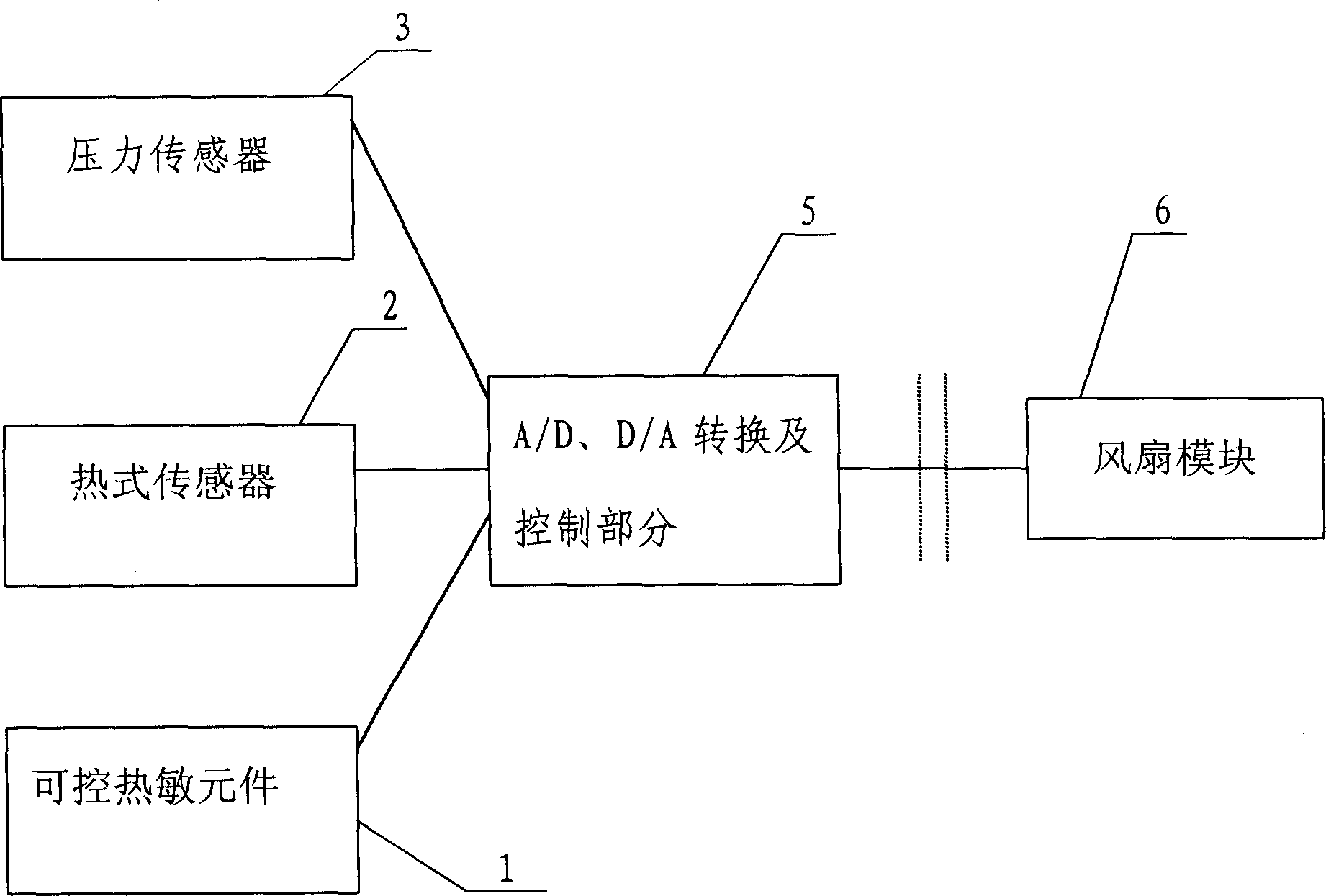

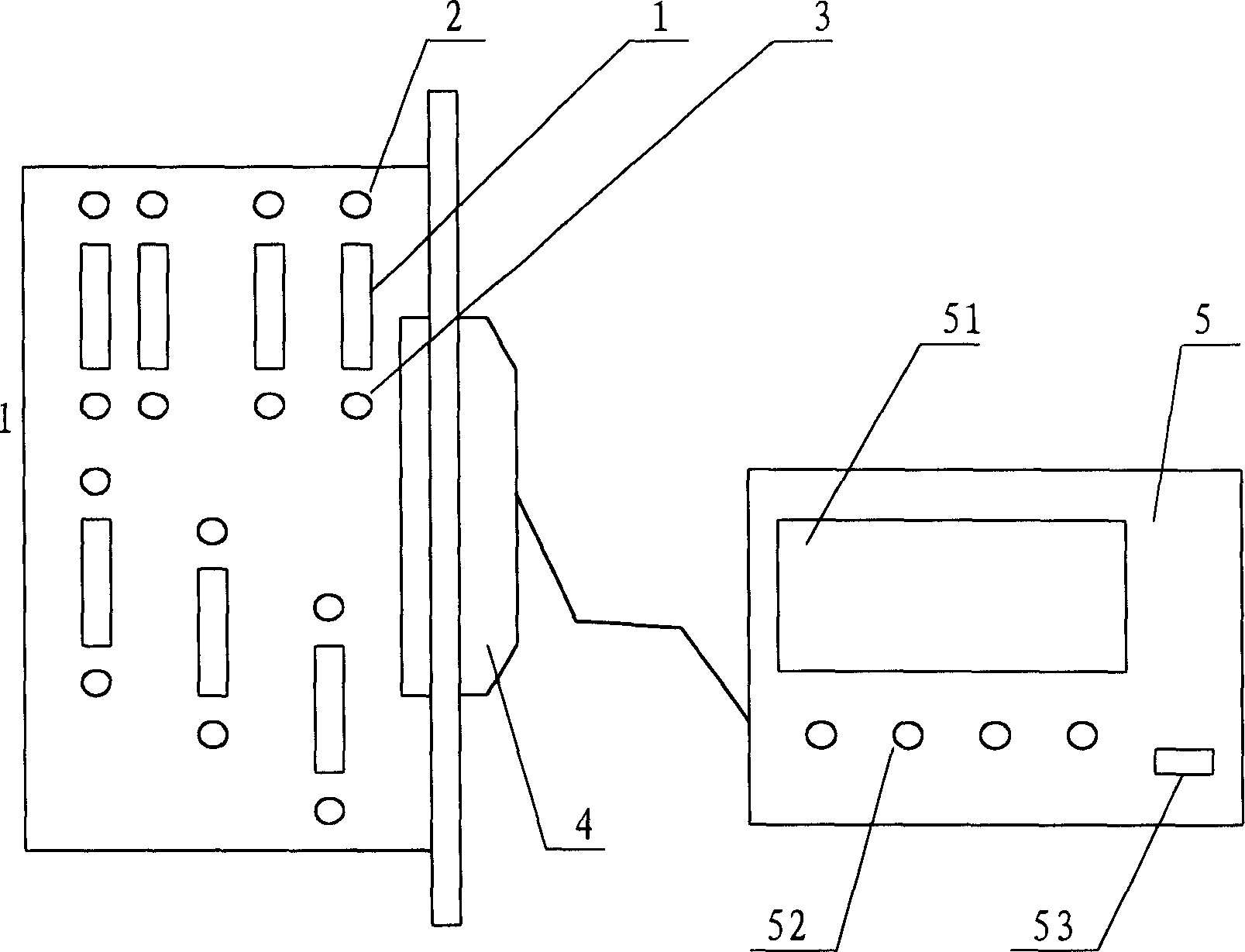

[0029] Such as Figure 1-Figure 3 Shown, thermal testing device described in the present invention comprises:

[0030] A controllable thermal element 1 used to simulate the heat source generated by the heating element;

[0031] Thermal sensor 2 for detecting temperature and wind speed signals;

[0032] A differential pressure sensor 3 for collecting pressure signals;

[0033] A multi-channel A / D, D / A conversion and control device 5 for converting multiple sets of temperature signals and pressure signals and controlling the controllable thermal element 1 and fan module 6;

[0034] A fan module that provides an air source for the analog board;

[0035] Among them, the layout of the controllable thermal element 1 analog communication equipment typical circuit board is installed on the analog single board 7, the thermal sensor 2 and the differential pressure sensor 3 are arranged on the analog single board 7 by plugging, and the thermal sensor 2 and the differential pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com