Active nano grade organic fine humic fertilizer and its production

A production method and nano-type technology, applied in the direction of organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of aggregate structure damage, soil compaction, and excessive harmful residues, so as to reduce nutrient precipitation, protect land resources, and improve crops quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The present invention comprises following components:

[0080] Ammonium humate (content HA30%~40%, nitrogen 5%), 580kg / T;

[0081] Organic nitrogen (46% nitrogen in urea), 120kg / T;

[0082] Ordinary calcium superphosphate (content 12%-20%), 200kg / T;

[0083] Ammonium phosphate (46% phosphorus content), 130kg / T;

[0084] Organic potassium (content 40% ~ 80%), 90kg / T;

[0085] Auxiliary additives (amino acids Fe, Cu, Mn, Zn, B, Mo) and active ingredients of Chinese herbal medicines, 20kg / T;

[0086] Process water 480kg / T.

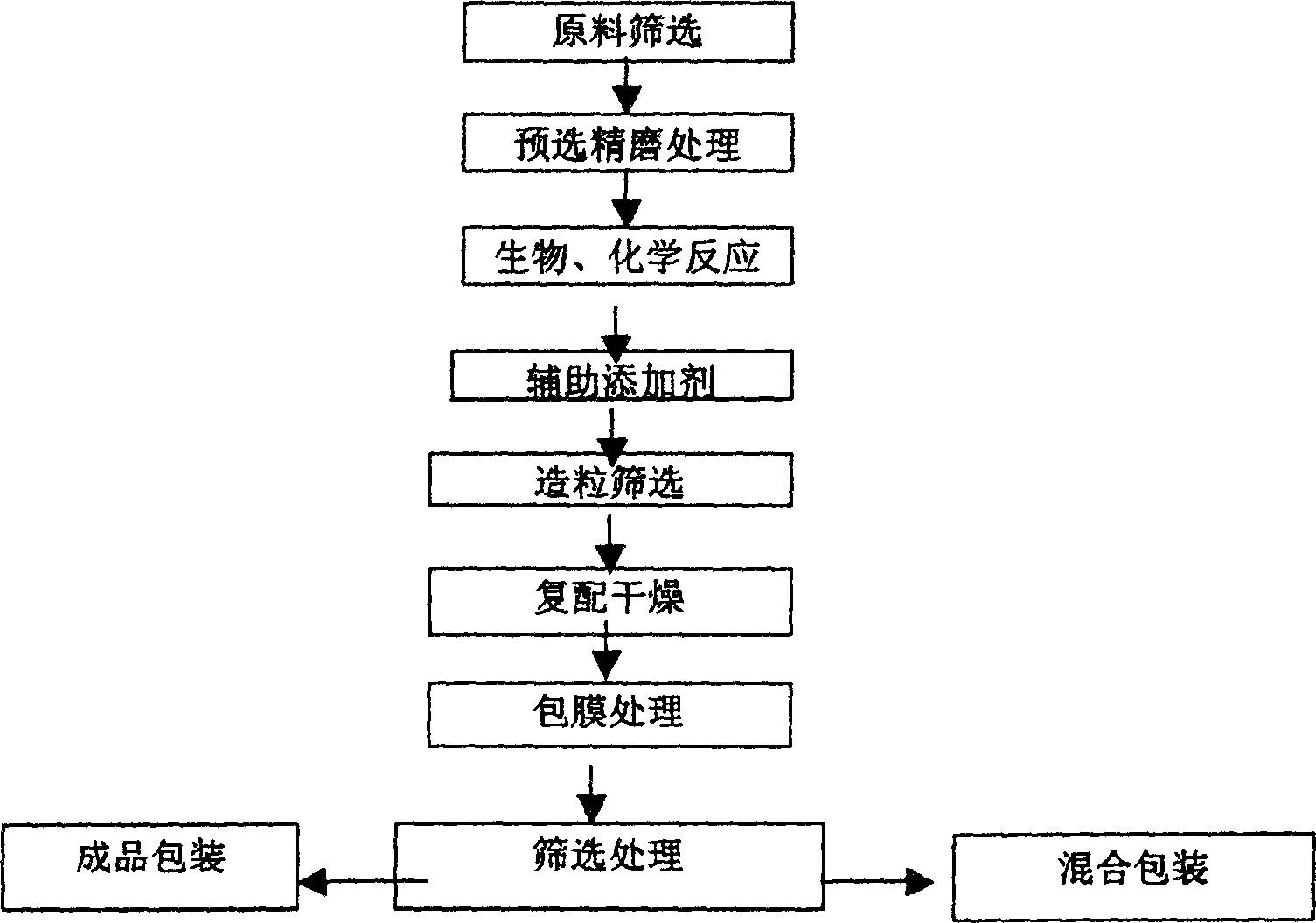

[0087] Its production process is:

[0088] 1) Raw material screening:

[0089] The content of peat lignite is 45% to 70%, and after cleaning, it becomes the raw material of active organic fine rotting fertilizer.

[0090] 2) Pre-select fine grinding treatment:

[0091] Grind 18-20NM by ball mill, and wash with water to remove impurities.

[0092] 3) Biological and chemical reactions:

[0093] Mix the raw materials of ammonium humic acid with ...

example 1

[0103] Example 1: special fertilizer for flowers, 35% organic fine rot fertilizer plus 65% biological fertilizer;

example 2

[0104] Example 2: special fertilizer for fruit trees, 75% organic fine rot fertilizer plus 25% biological fertilizer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com