Grain prolamin microsphere and preparation method

A gliadin and grain technology, applied in the directions of microcapsules, non-active components of polymer compounds, bulk delivery, etc., can solve problems such as being difficult to remove, achieve good containment efficiency, uniform particle size distribution, and reduce drug side effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1.8 ml of absolute ethanol and 4 ml of water were mixed, then 400 mg of corn or wheat prolamin was added, and the mixture was vortexed to completely dissolve the substance (the prolamin content was 33.3 mg / ml).

[0023] 2. Under the circumstance that the above mixture is shaken violently, quickly add 8ml of water to mix the solution quickly to form a grain-containing gliadin-containing drug microsphere suspension (ethanol content 40%, gliadin 20mg / ml) .

[0024] 3. The suspension is vacuum-dried or freeze-dried to obtain cereal prolamin microspheres.

Embodiment 2

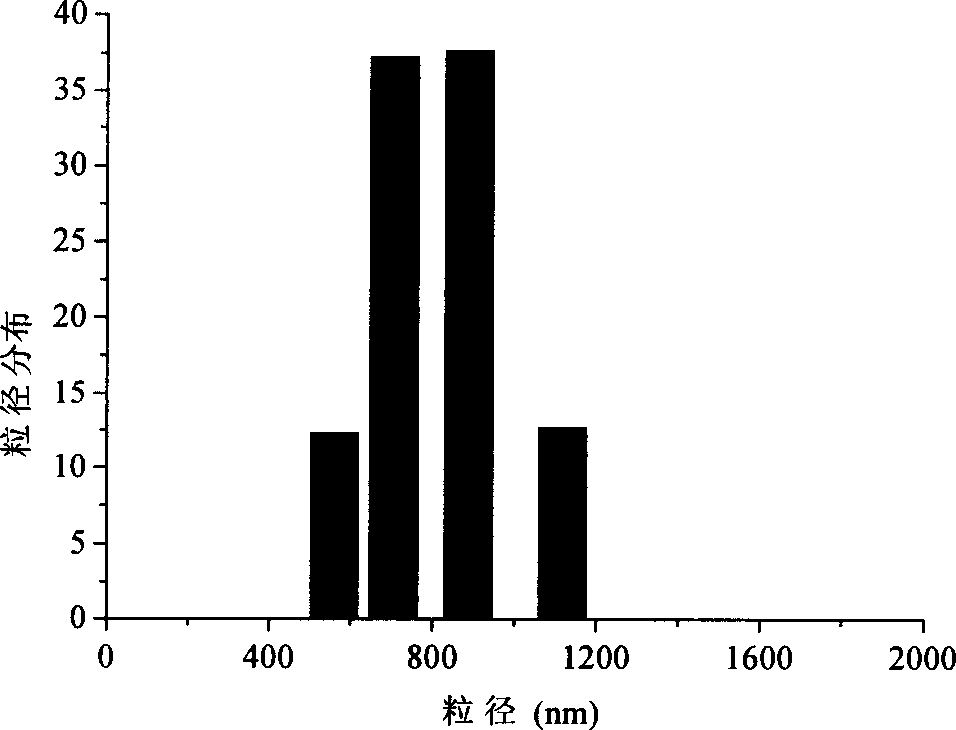

[0026] After diluting the 20 mg / ml cereal prolamin suspension prepared in Example 1 by 10 times, the measurement results of particle size distribution by light scattering are as follows: figure 1 shown. Wherein, the ordinate is the particle size distribution of the cereal gliadin microspheres, and the abscissa is the particle size (nm) of the cereal prolamin microspheres. It shows that the particle size distribution of the prepared cereal prolamin microspheres is between 500-1200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com