Vibration bed membrane separator

A membrane separator and vibrating bed technology, applied in the field of special equipment, can solve the problems of complicated membrane system control, increased processing difficulty, and many valves, and achieve the effects of low power consumption, reduced processing costs, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

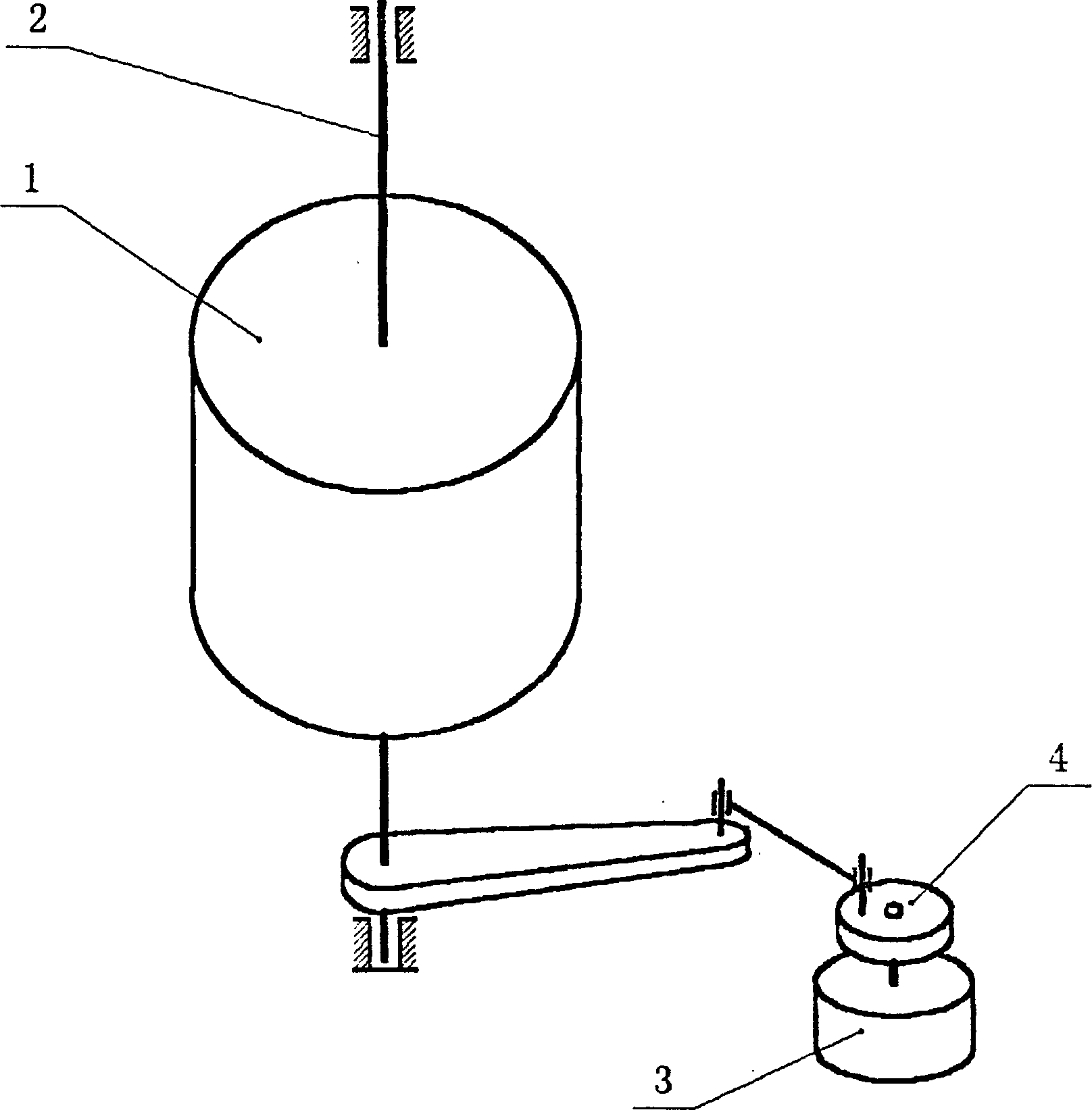

[0025] See figure 1 : The flat membrane separator 1 is horizontally arranged on the central axis 2 vertical to the ground, driven by the eccentric link mechanism 4 of the motor 3, the central axis can reciprocate and swing within a certain radial angle, so that a horizontal shear force is generated on the membrane surface . Under the action of this force, the fouling layer deposited on the horizontal membrane surface is reduced or destroyed by the shear force, and the work of the membrane separator is less affected by the fouling.

Embodiment 2

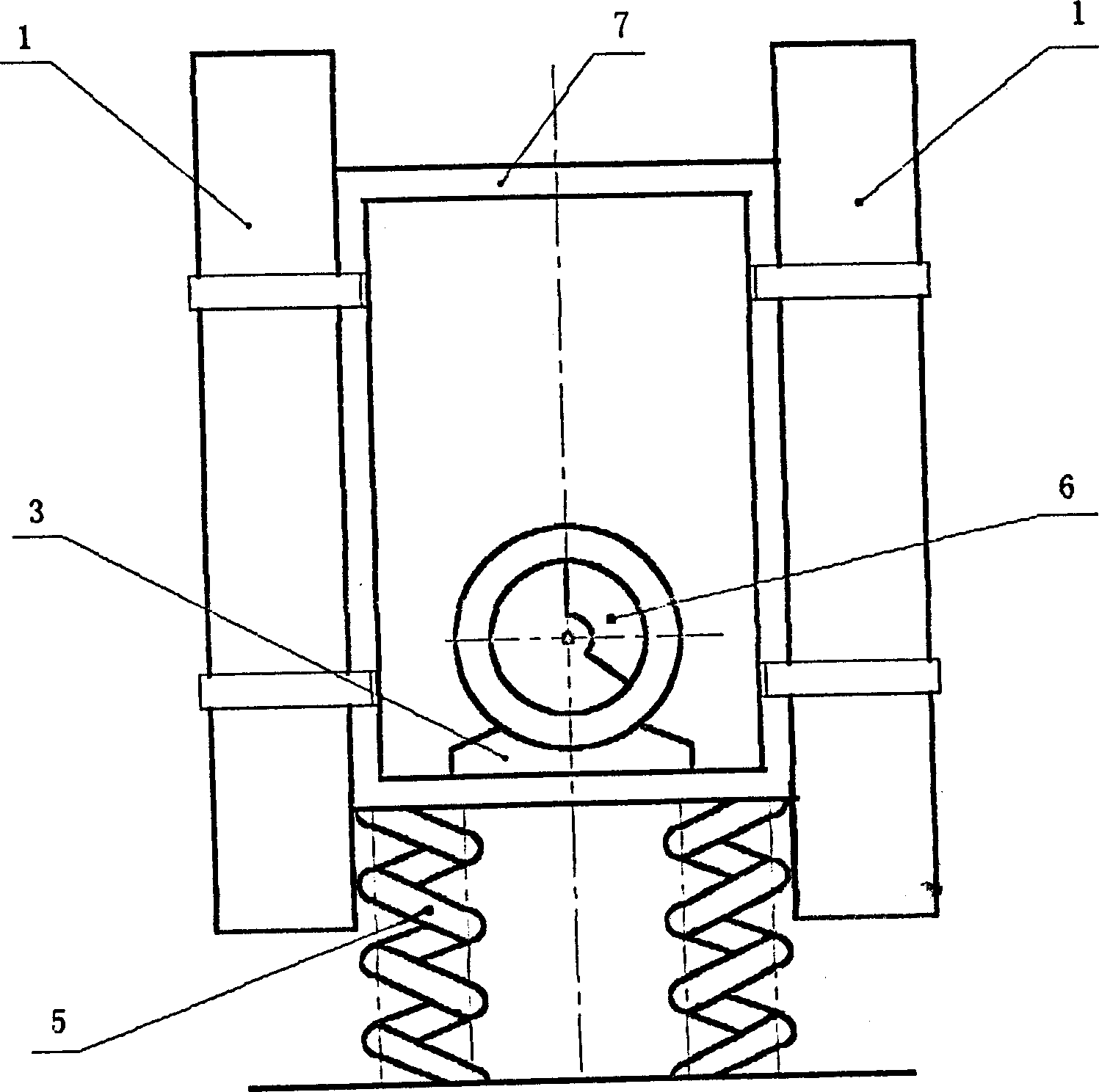

[0027] See figure 2 Roll-type membrane separator 1 is vertically fixed on the vibrating frame 7, the vibrating frame is supported on the spring 5, the material passes through the membrane tube from the horizontal direction, the motor 3 is also fixed on the frame 7, and the rotating shaft of the motor 3 is fixed with an eccentric weight Object 6. When the motor 3 rotates at high speed, the eccentric weight 6 generates a reciprocating vibration force on the vibrating frame 7, causing the vibrating frame 7 to reciprocate up and down, and the vibrating frame 7 drives the membrane separator 1 to shake and reciprocate up and down. Therefore, the substances adhered to the membrane surface of the vertically arranged tubular membrane separator 1 are destroyed by the shear force, reducing or no longer affecting the work of the membrane separator.

Embodiment 3

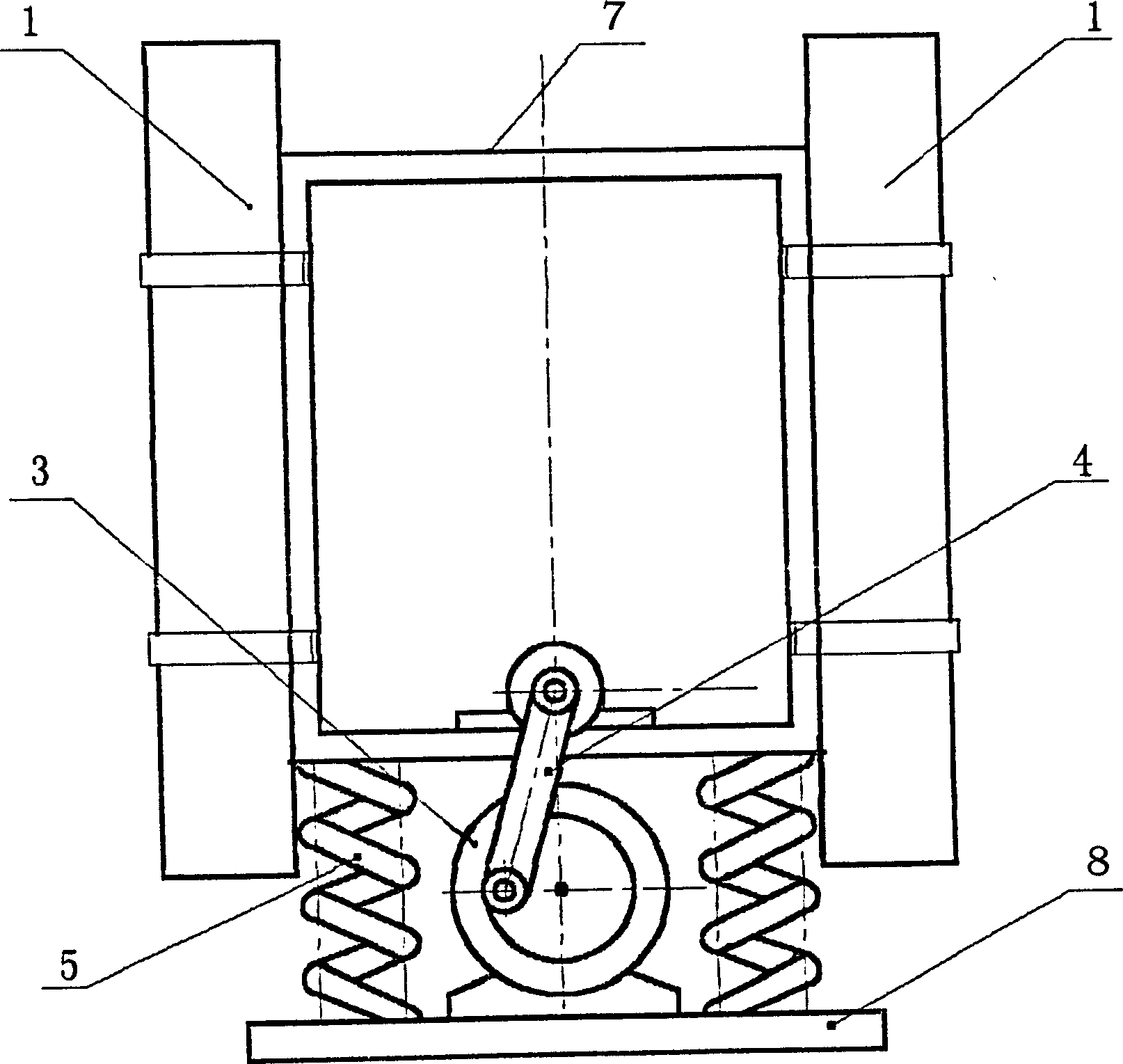

[0029] See image 3 The tube-membrane separator 1 is fixed on the vibrating frame 7, and the vibrating frame 7 is supported on the spring 5, and the material passes through the membrane tube in the horizontal direction. The motor 3 and the spring 5 are fixed on the spring base plate 8, and the vibrating frame 7 and the membrane separator 1 are reciprocated up and down through the eccentric link mechanism 4, so that the material adhered to the membrane tube wall of the membrane separator 1 is subjected to shear force Destroy, reduce or no longer affect the operation of the membrane separator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com