Acrylic purification tower

A light removal tower and acrylic acid technology, applied in distillation and separation, organic chemistry, chemical instruments and methods, etc., can solve the problems of increasing unit consumption of acrylic acid, excessively high, affecting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

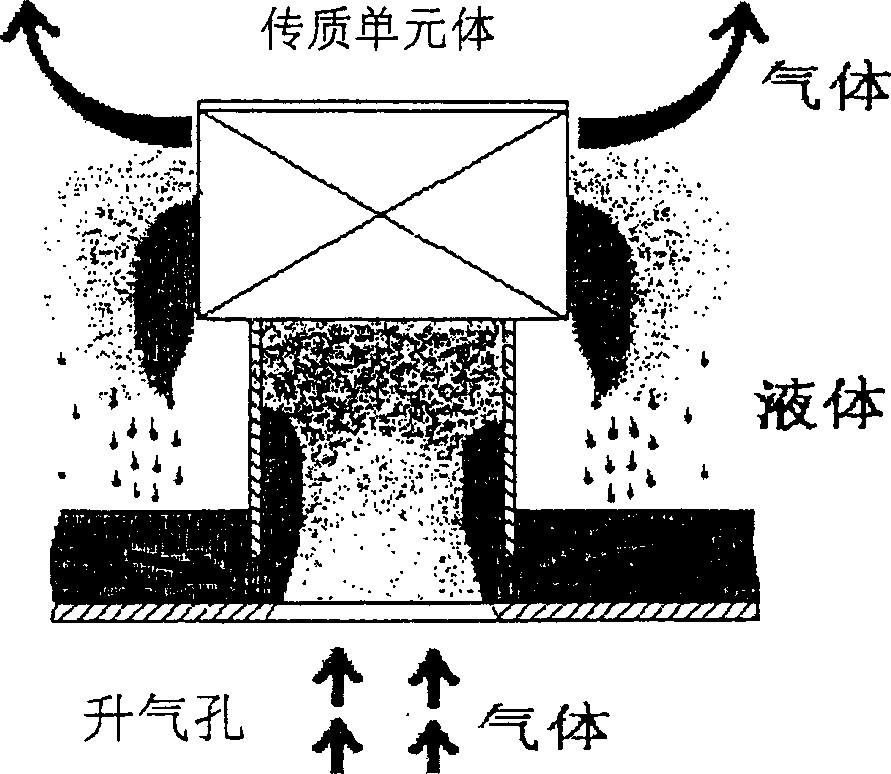

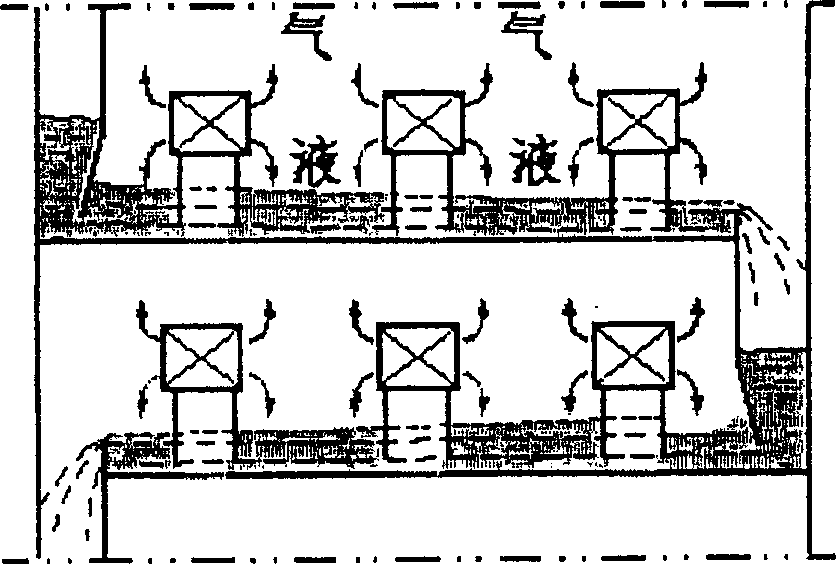

[0027] The total number of trays in the acrylic acid purification and light removal tower is 21 trays, and the feed port is between 11 and 12 trays. The stripping section of the tower adopts 11 large-hole through-flow type with an opening ratio of 10-20%. Sieve tray, 10 co-current jet trays are used in the rectification section (such as image 3 Shown), the inner diameter of the tower is 1400mm. The mass transfer unit of the tray adopts a packing-free structure, the purpose is to prevent a small amount of polymer that may be generated in the rectification section from clogging the tray, and if a small amount of polymer is generated, it is easy to remove. The height of the overflow weir is 10mm. During implementation, the content of acetic acid at the bottom of the tower is less than 2%, the loss of acrylic acid at the top of the tower is less than 2%, the pressure drop of the whole tower is about 6kpa, and the operating temperature at the bottom of the tower is about 85°C. Th...

Embodiment 2

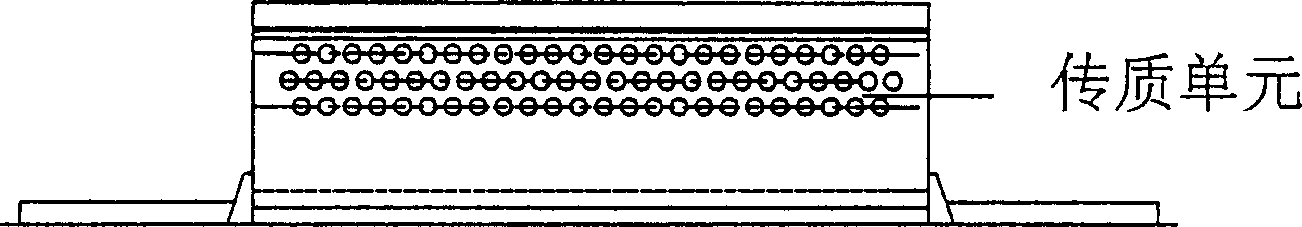

[0029] On the basis of embodiment 1, the 5 unpacked co-current jet trays in the upper part of the rectification section are replaced with packed co-current jet trays (such as Figure 4shown), the remaining 5 blocks remain unchanged, and holes are opened on the upper part of the mass transfer unit to further reduce the pressure drop of the device. At the same time, in order to enhance the gas-liquid mass transfer effect, the height of the overflow weir is increased to 20mm. During implementation, the content of acetic acid at the bottom of the tower is controlled below 2.%, the loss of acrylic acid at the top of the tower is below 1.5%, the pressure drop of the whole tower remains about 6kpa, and the temperature at the bottom of the tower has been controlled below 82°C. The number of theoretical plates in the stripping section has not changed, but the number of theoretical plates in the rectifying section has increased to 4, and the number of theoretical plates in the whole col...

Embodiment 3

[0031] On the basis of Example 1, the 3 large-pore sieve trays near the rectification section in the upper part of the stripping section were replaced with filler-free co-flow jet trays, and 10 co-flow jet trays were still used in the rectification section. During the implementation process , the content of acetic acid at the bottom of the tower is controlled below 1.5%, the loss of acrylic acid at the top of the tower is below 1.0%, the pressure drop of the whole tower remains about 6.5kpa, and the temperature at the bottom of the tower is controlled at 83°C. The theoretical tray number of the whole tower is 7 trays. Under this operating condition, the processing capacity of the device exceeds 3500kg / h, and the production cycle reaches more than 120 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com