A kind of viscosity reducer for ultra-high performance concrete and preparation method thereof

An ultra-high performance, viscosity reducing agent technology, applied in the field of concrete admixtures, can solve problems such as difficulty in application, and achieve the effect of enhancing dispersion performance, reducing aggregation tendency, and enhancing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

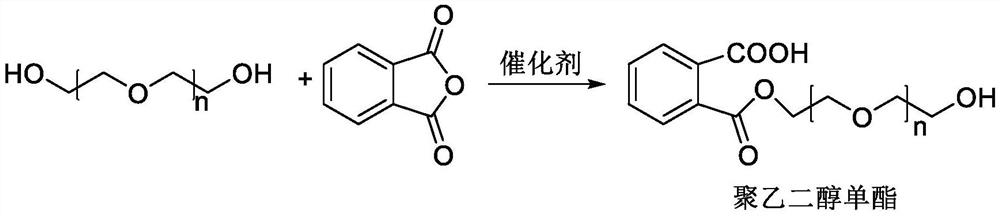

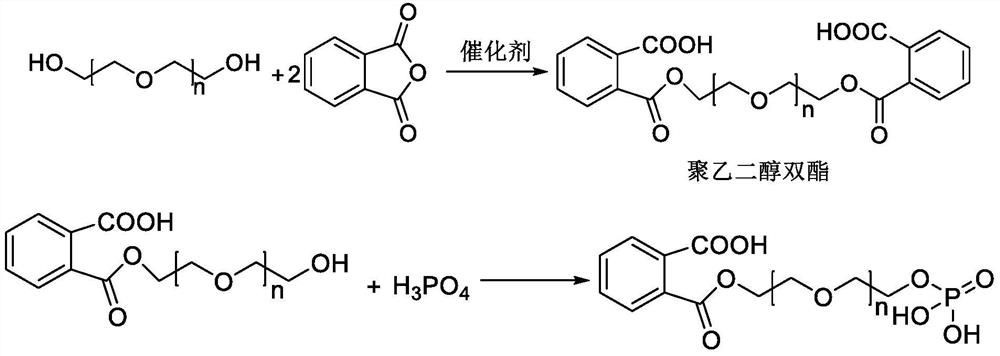

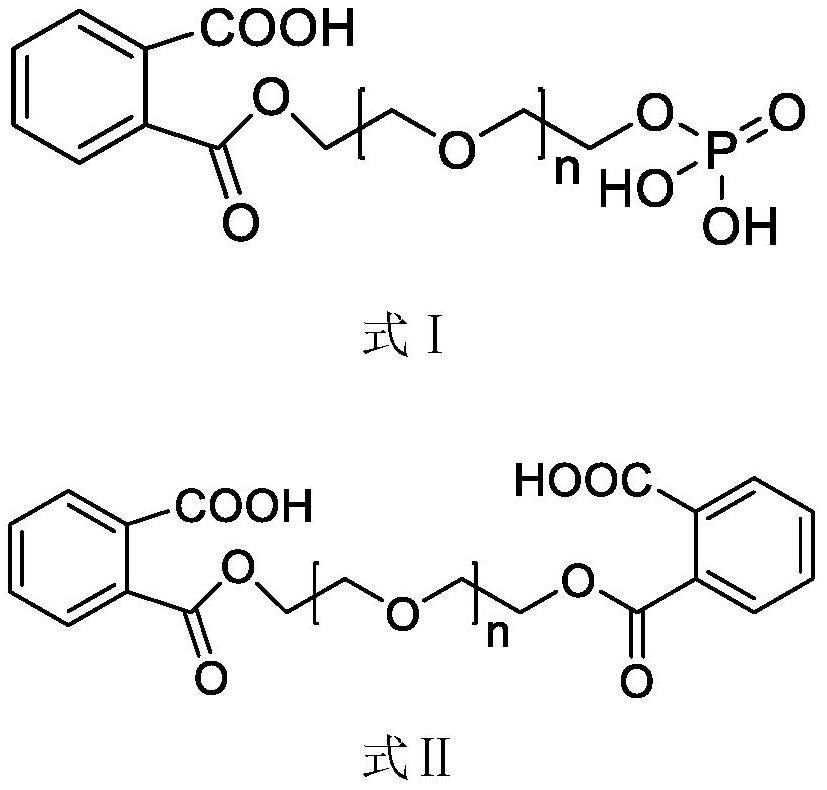

Method used

Image

Examples

Embodiment 1

[0028] Add 500g of polyethylene glycol (weight average molecular weight 200g / mol) into a four-necked flask, raise the temperature to 30°C, stir, then add 185g of phthalic anhydride, then add 0.1g of concentrated sulfuric acid, stir for 2 hours, add 100g Phosphoric acid, 50g of water, heated up to 60°C, stirred for 2 hours to obtain a reddish-brown liquid which is the viscosity reducer (solid content 94.0%). At the end of the reaction, the phthalic anhydride content in the reaction solution was monitored by HPLC to be less than 5%, and the phosphate content was determined to be less than 6% by titration. The following examples are the same as this method. (HPLC detection method and titration method measure phosphate radical content are routine standard methods, do not repeat at this)

Embodiment 2

[0030] Add polypropylene glycol 500g (weight average molecular weight 800g / mol) in four-neck flask, heat up to 40 DEG C, stir, then add phthalic anhydride 46g, then add 0.1g concentrated sulfuric acid, stir and react for 1 hour, add phosphoric acid aqueous solution ( 25g phosphoric acid and the mixture of 20g water), be warming up to 50 ℃, stir 3 hours to obtain reddish-brown liquid and be viscosity reducing agent (solid content 96.6%).

Embodiment 3

[0032] Add 500g of polypropylene glycol (weight average molecular weight: 2000g / mol) into a four-neck flask, raise the temperature to 40°C, stir, then add 18.5g of phthalic anhydride, then add 0.1g of p-toluenesulfonic acid, stir for 2 hours, add Phosphoric acid aqueous solution (a mixture of 10g polyphosphoric acid and 10g water), heated up to 60°C, stirred for 2 hours to obtain a reddish-brown liquid which is the viscosity reducer (solid content 98%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com