Preparation method for textile defoamer

A technology of defoaming agent and preparation steps, which is applied in the field of preparation of textile defoaming agent, can solve the problems of poor defoaming ability, slow defoaming of defoaming agent, low efficiency, etc., and achieve the effect of stable existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

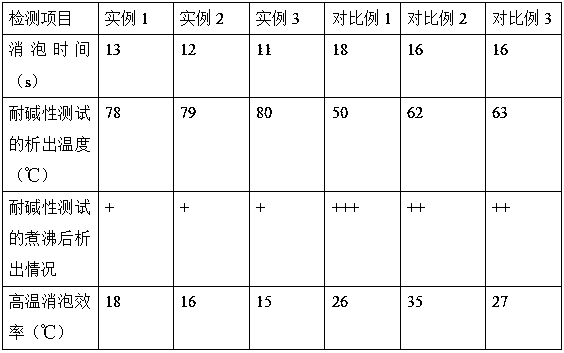

Examples

Embodiment 1

[0030] The emulsifier is: nonylphenol polyoxyethylene ether

[0031] Preparation of epoxidized soybean oil:

[0032] Weigh 800g of soybeans, crush them in a crusher for 40 minutes to obtain bean dregs, soak the bean dregs with 500mL of n-hexane, stir for 30 minutes, soak for 3 hours, filter and remove the residue to obtain the leachate, pour the leachate into the extraction container, extract and wash 3 times , wash with 400mL of water each time to obtain mixed oil, place the mixed oil in an evaporator, heat up to 70°C, evaporate for 2 hours, remove the distilled liquid, and obtain soybean oil;

[0033] In parts by weight, in a four-necked flask with a thermometer, a stirrer, and a reflux condenser, 70 parts of soybean oil, 20 parts of mass fraction are 25% formic acid solution, 10 parts of mass fraction are 20% hydrogen peroxide and 20 parts of sulfuric acid with a mass fraction of 65%, heated to 80°C, started the agitator, stirred at a speed of 300r / min, and reacted for 2 h...

Embodiment 2

[0040] The emulsifier is: octylphenol polyoxyethylene ether

[0041] Preparation of epoxidized soybean oil:

[0042] Weigh 900g of soybeans, place the soybeans in a crusher and crush them for 45 minutes to obtain bean dregs, soak the bean dregs with 550mL of n-hexane, stir for 37 minutes, soak for 3.5 hours, filter and remove the residue to obtain the leachate, pour the leachate into the extraction container, extract and wash with water for 4 Once, wash with 450mL of water each time to obtain mixed oil, place the mixed oil in an evaporator, heat up to 75°C, evaporate for 2.5h, remove the distilled liquid, and obtain soybean oil;

[0043] In parts by weight, in a four-necked flask with a thermometer, a stirrer, and a reflux condenser, 75 parts of soybean oil, 22 parts of mass fraction are 25% formic acid solution, 11 parts of mass fraction are 20% hydrogen peroxide and 25 parts of sulfuric acid with a mass fraction of 65%, heated to 82°C, started the agitator, stirred at a spe...

Embodiment 3

[0050] The emulsifier is: polyoxyethylene laurate

[0051] Preparation of epoxidized soybean oil:

[0052] Weigh 1000g of soybeans, crush them in a crusher for 50 minutes to obtain bean dregs, soak the bean dregs with 600mL of n-hexane, stir for 45 minutes, soak for 4 hours, filter and remove the residue to obtain the leachate, pour the leachate into the extraction container, extract and wash 5 times , wash with 500mL of water each time to obtain mixed oil, place the mixed oil in an evaporator, heat up to 80°C, evaporate for 3 hours, remove the distilled liquid, and obtain soybean oil;

[0053] In parts by weight, in a four-necked flask with a thermometer, a stirrer, and a reflux condenser, 80 parts of soybean oil, 25 parts of mass fraction are 25% formic acid solution, 12 parts of mass fraction are 20% hydrogen peroxide and 30 parts of sulfuric acid with a mass fraction of 65%, heated to 85°C, started the agitator, stirred at a speed of 350r / min, and reacted for 3 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com