Microirrigation water-irrigating device anti-blocking and hydraulic performance integrated test device

A technology for hydraulic performance and comprehensive testing, which is used in the testing of measuring devices, watering devices, and machine/structural components. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

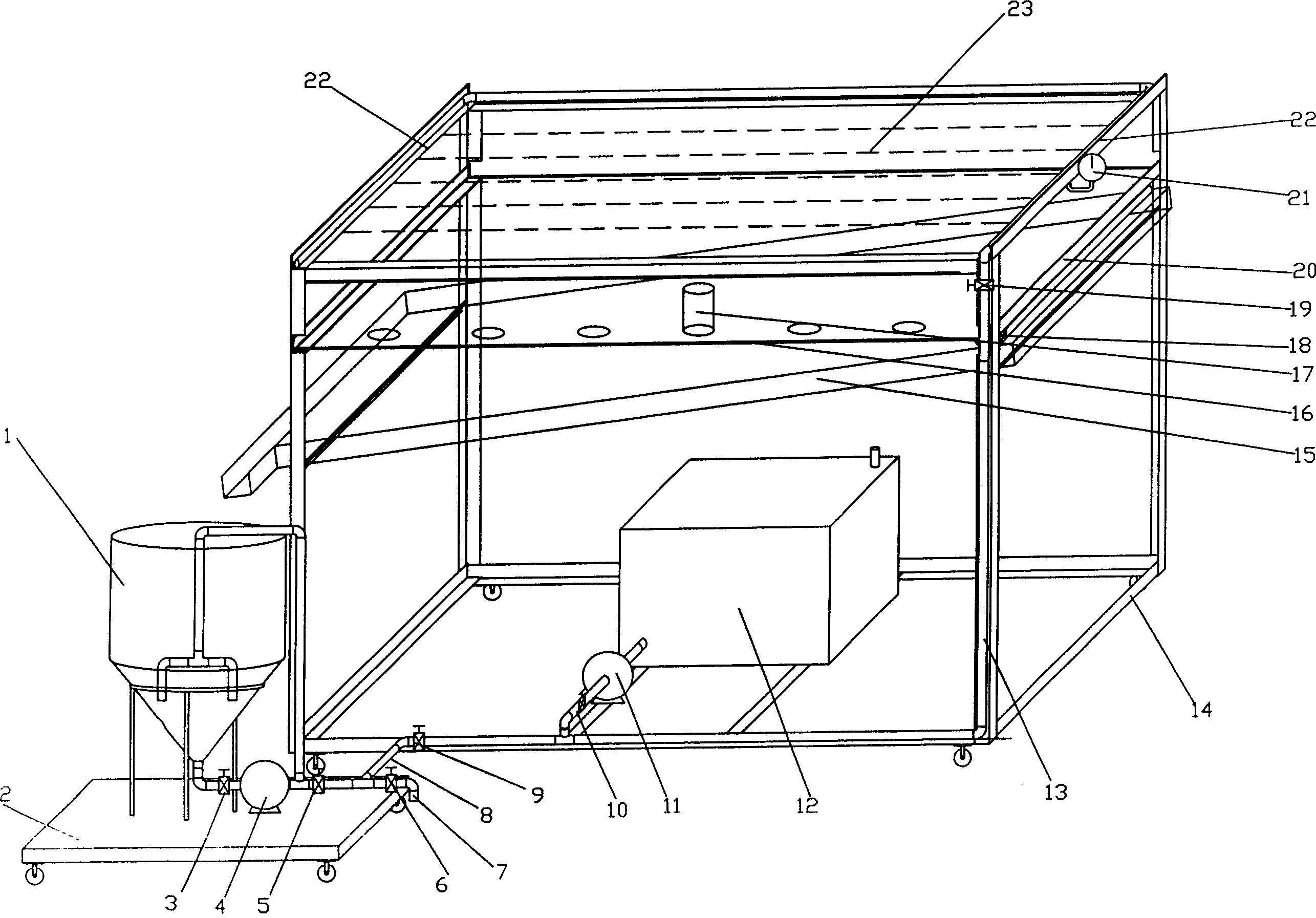

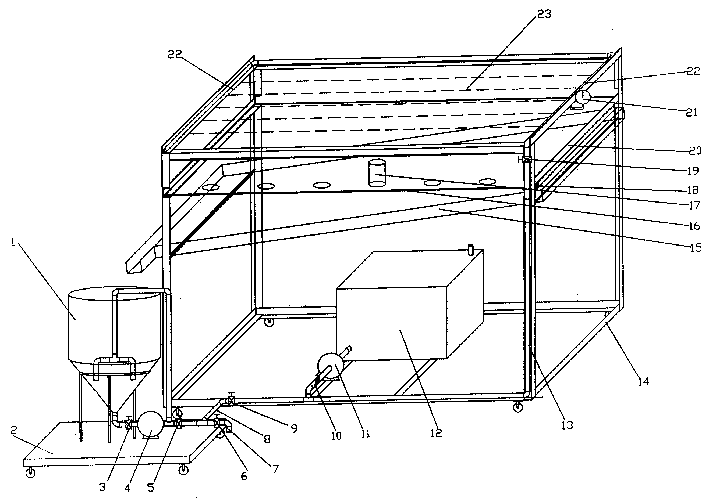

[0037] The specific content of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] In the figure: 1 is the mixing tank, 2 is the movable vehicle, for the convenience of moving the device, 3 is the control valve, 4 is the booster pump, 5 and 6 are the control valves, 7 is the drain port, 8 is the connecting hose, 9 10 is a control valve, 11 is a booster pump, 12 is an adjustable constant water tank, 13 is a water delivery pipe (PVC or stainless steel pipe), 14 is a movable test frame, 15 is an inclined water collecting plate tank, and 16 is a movable Horizontal plate, 17 is a water collection cup or self-recording water volume sensor, 18,19 is a control valve, 20 is a multi-port flushing pipe, 21 is a pressure measuring device, 22 is a branch pipe, and 23 is a capillary or drip irrigation pipe.

[0039] like figure 1 As shown, the device includes the following parts:

[0040] Support 14-plays integral supporting effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com