Method for etching surface material with induced chemical reaction by focused electron beam on surface

A technology of focusing electron beams and chemical reactions, which is applied in the processing of photosensitive materials, originals for photomechanical processing, and photoplate-making processes on patterned surfaces, and can solve problems such as opacity, transparency defects, and lack of absorbent materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

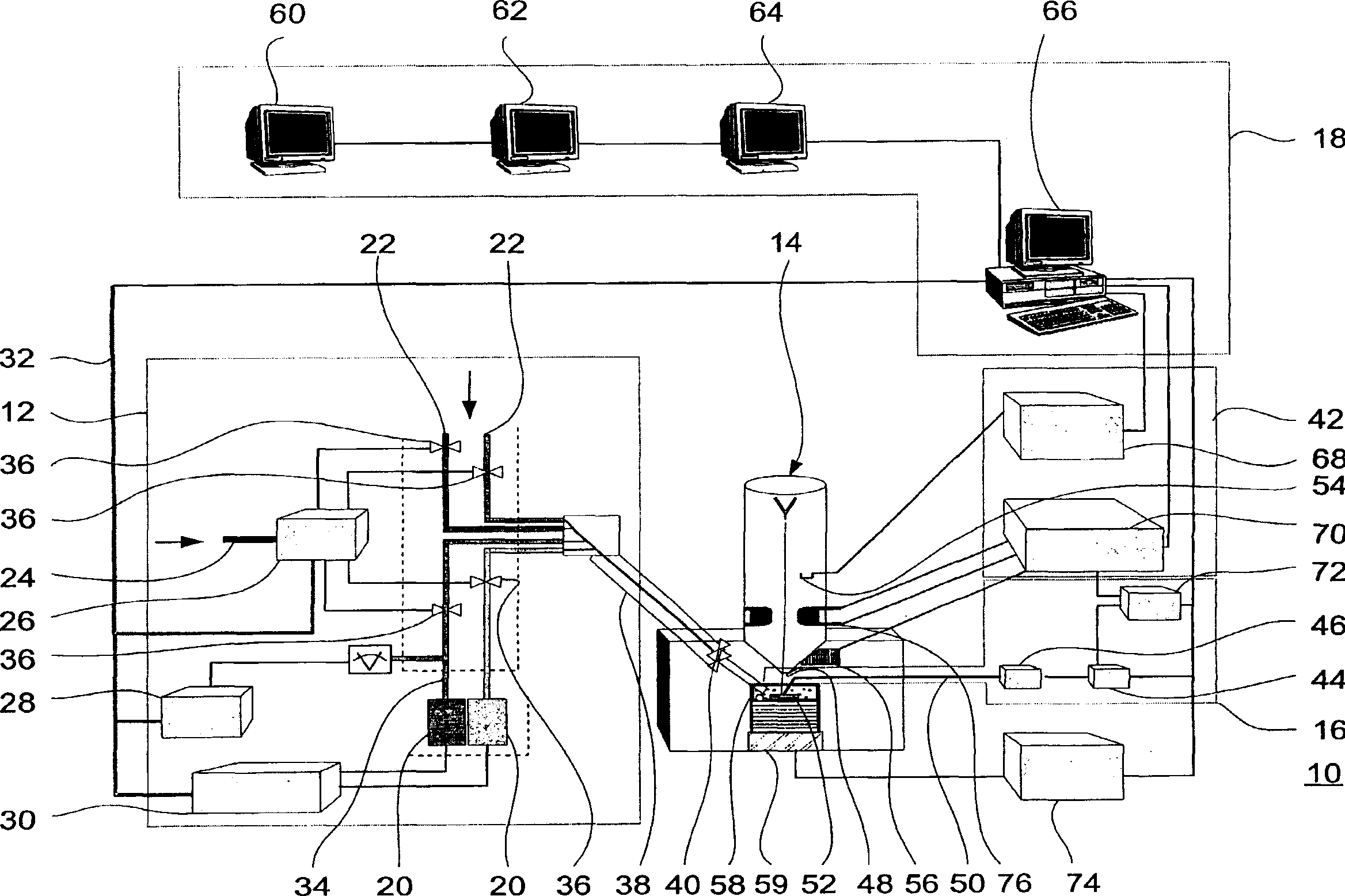

[0045] figure 1 Shown is a schematic assembly diagram of a mask repair system 10 according to the method of the present invention, having a known molecular beam delivery system, hereinafter referred to as gas delivery system 12; a known electron beam system 14; a known photon beam system, hereinafter referred to as the laser beam system 16; and the computer control system 18 for triggering operations in due time and coordinating the beams - molecular beams, photon beams and electron beams.

[0046] The gas supply system 12 comprises a reservoir 20 for liquid or solid precursor - Peltier cooled -; a feed line 22 for a gaseous precursor; a feed line 24 for compressed air; a valve control 26, a pressure gauge 28 and a Temperature control 30 in reservoir 20 . Connection Valve control 26, pressure gauge 28 and temperature gauge are connected to computer control system 18 by means of a CAN open bus.

[0047] The reservoir 20 is connected to a nozzle header 38 by means of a feed pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com