Wind turbine rotor blade and lightening discharge receptor with drain passage

A technology of wind turbines and rotor blades, which is applied in the direction of wind engines, wind generator components, and wind engines consistent with the wind direction, and can solve problems such as interfering with the rotation of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

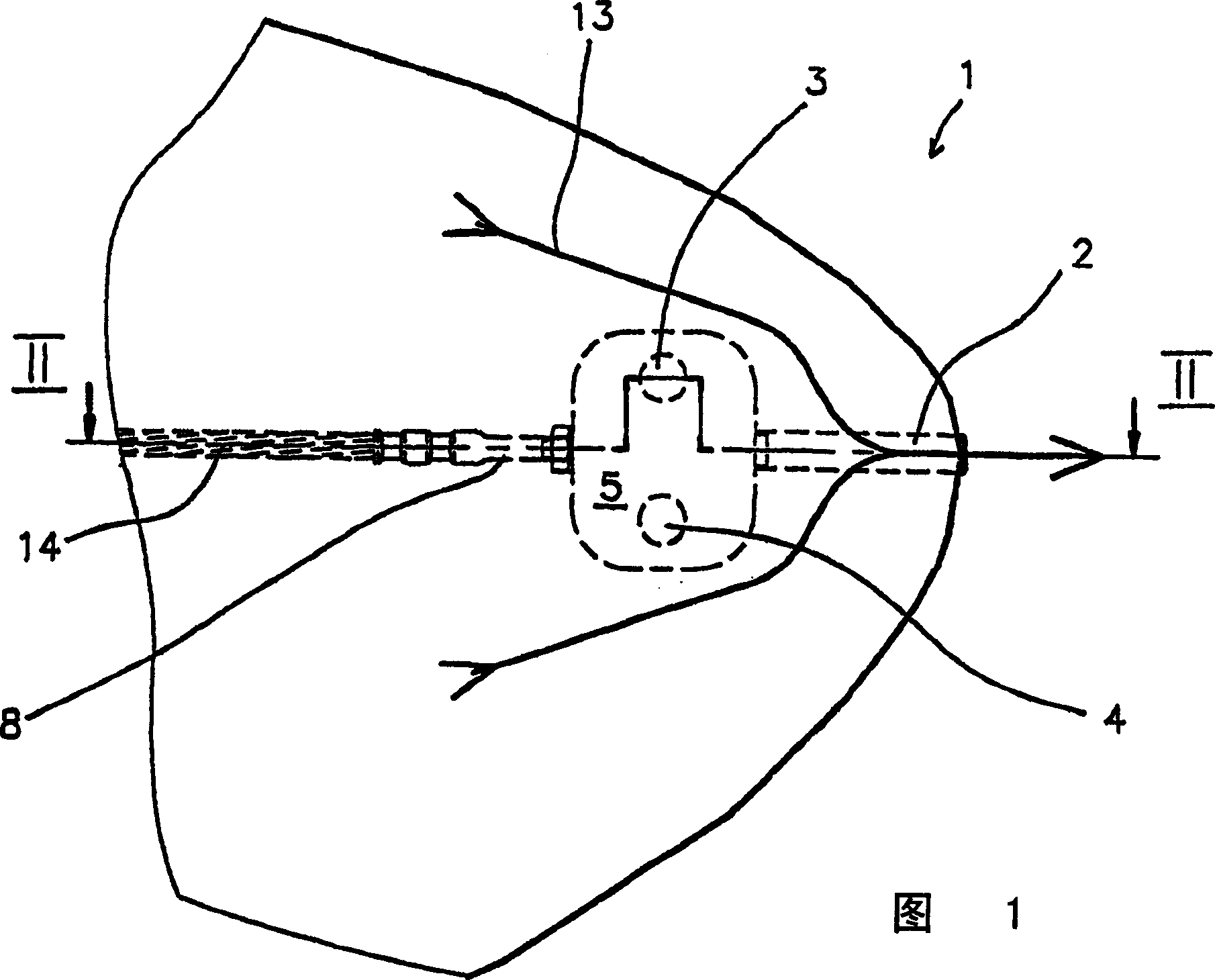

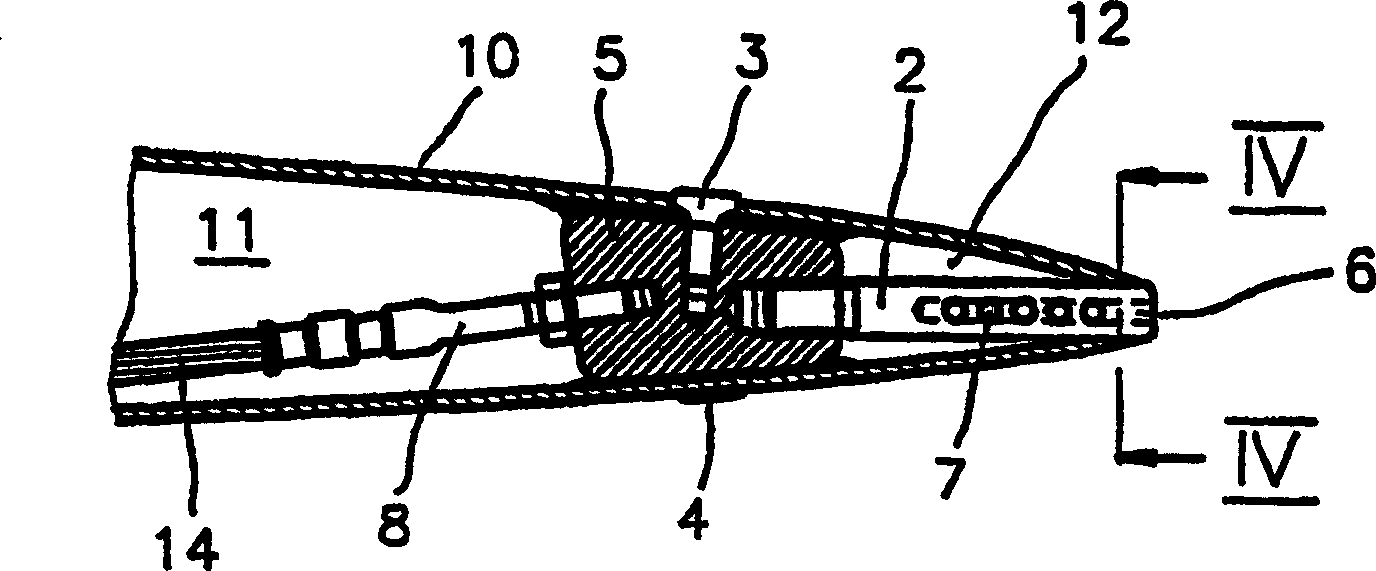

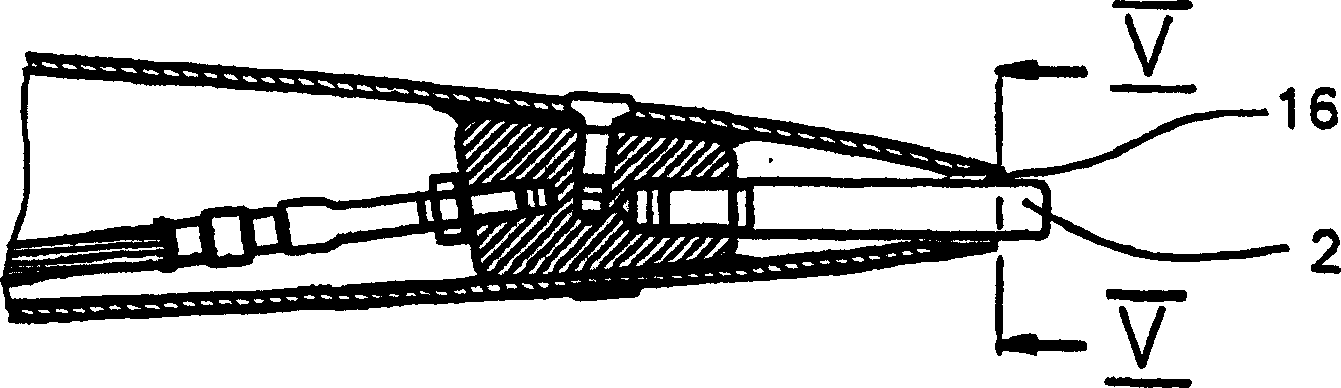

[0019] Figure 1 is a schematic view of the top of the blade, seen from one side of the blade, according to a first embodiment of the invention. A lightning discharge lower lead 14 in the form of a copper cable is screwed onto an anchor block 5 via an end fitting 8 . Three lightning discharge receptors 2, 3, 4, such as tungsten, are connected to an anchor block 5 made of conductive material such as stainless steel, red brass or red copper by screw connections, said lightning discharge receptors The free ends extending from the anchor block 5 to the blade top 1 are respectively the pressure side of the blade top and the suction side of the blade top. In the embodiment shown in Figures 1, 2 and 4, a discharge channel 6 is provided in the lightning discharge receiver 2 extending from that anchor block 5 to the free end of the blade top. Arrow 13 in Fig. 1 indicates how water is discharged from the inside of the blade to the outside of the blade through the discharge channel 6 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com