Bearing appts. its mfg. method, bearing table appts, and exposure appts.

A supporting device and manufacturing method technology, applied in the direction of photolithography exposure device, microlithography exposure equipment, semiconductor/solid-state device manufacturing, etc., can solve the problems of increasing the volume of the air spring, the difficulty of large volume, and low rigidity. Achieve the effect of preventing enlargement and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

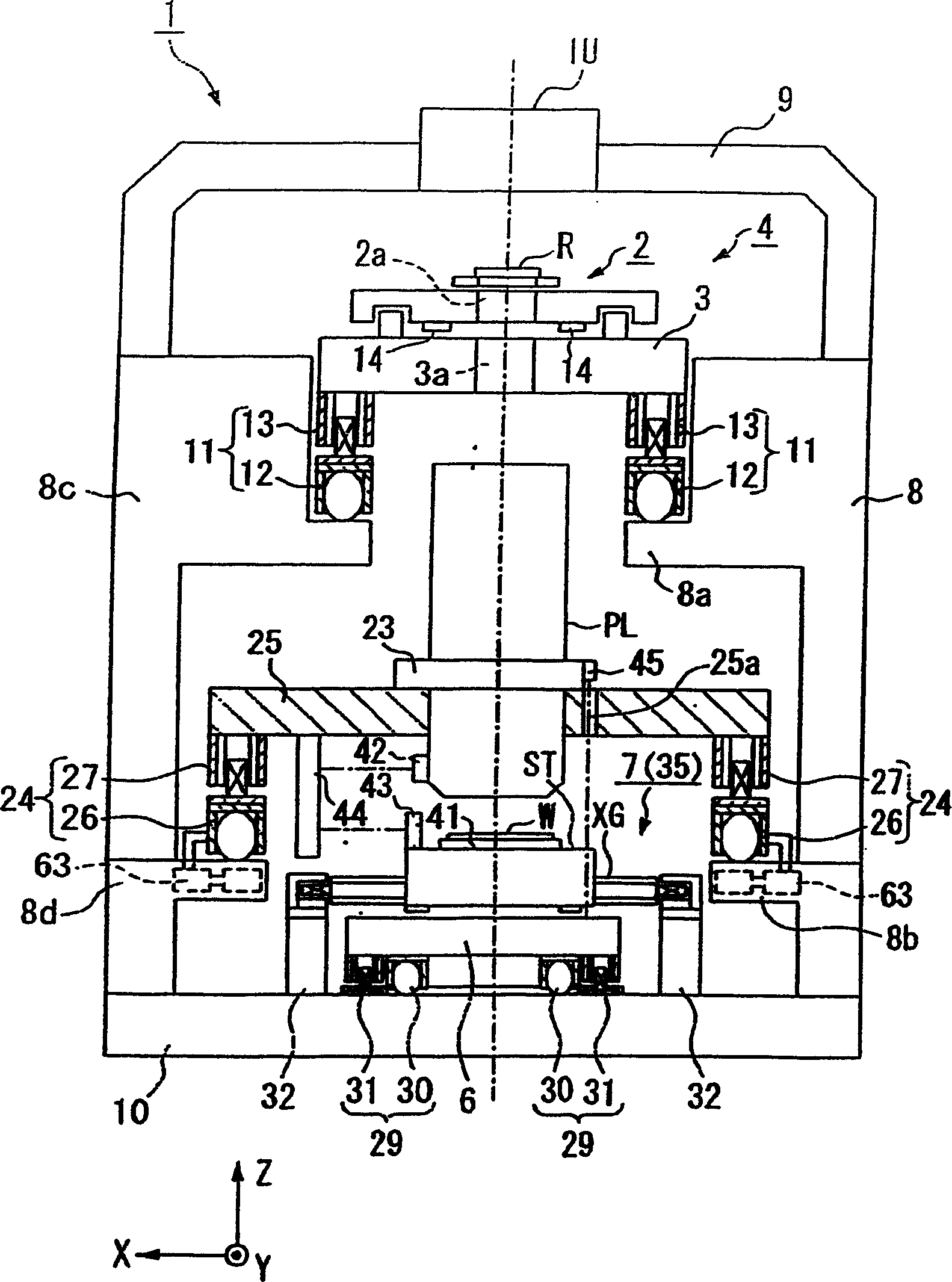

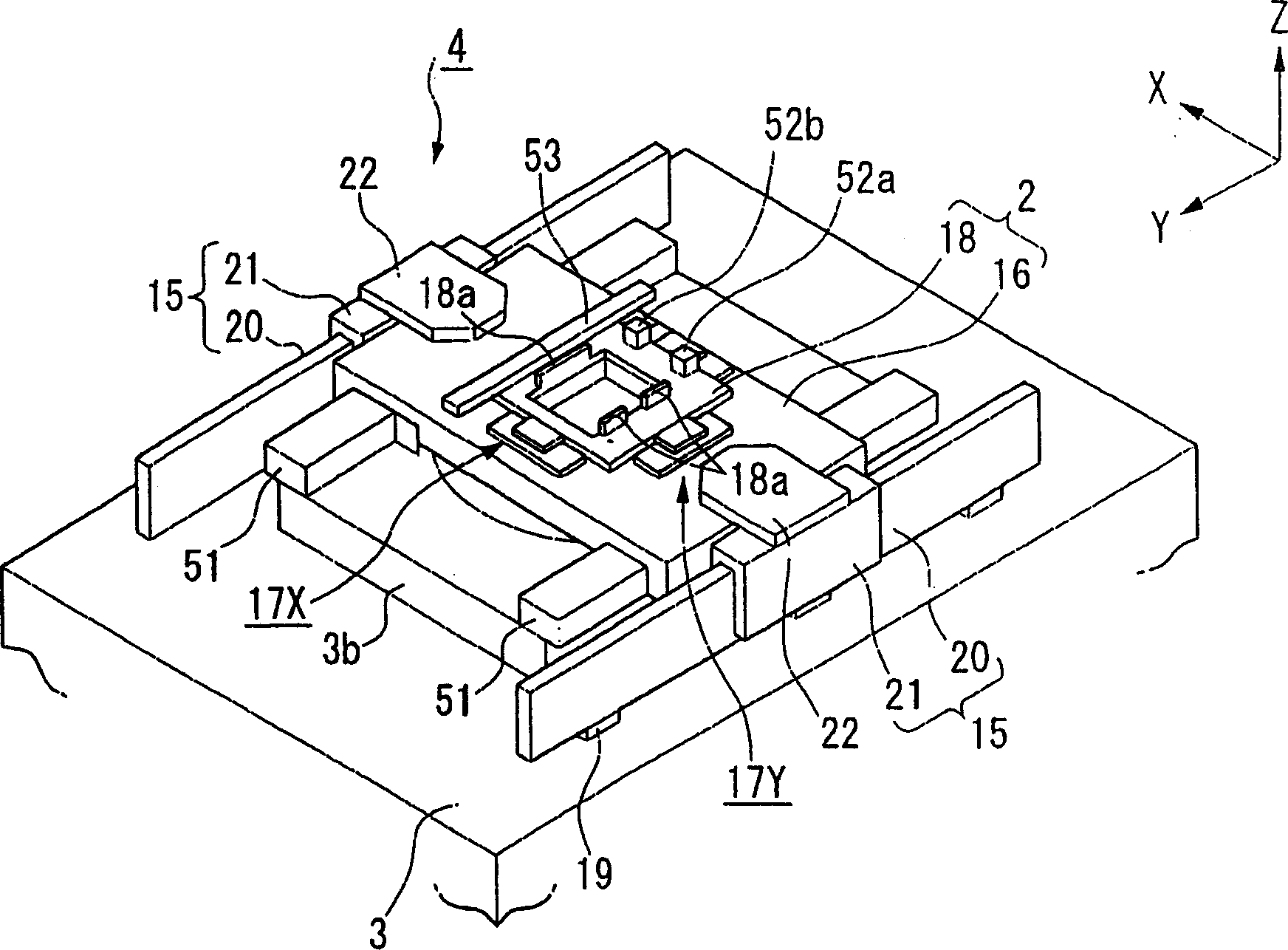

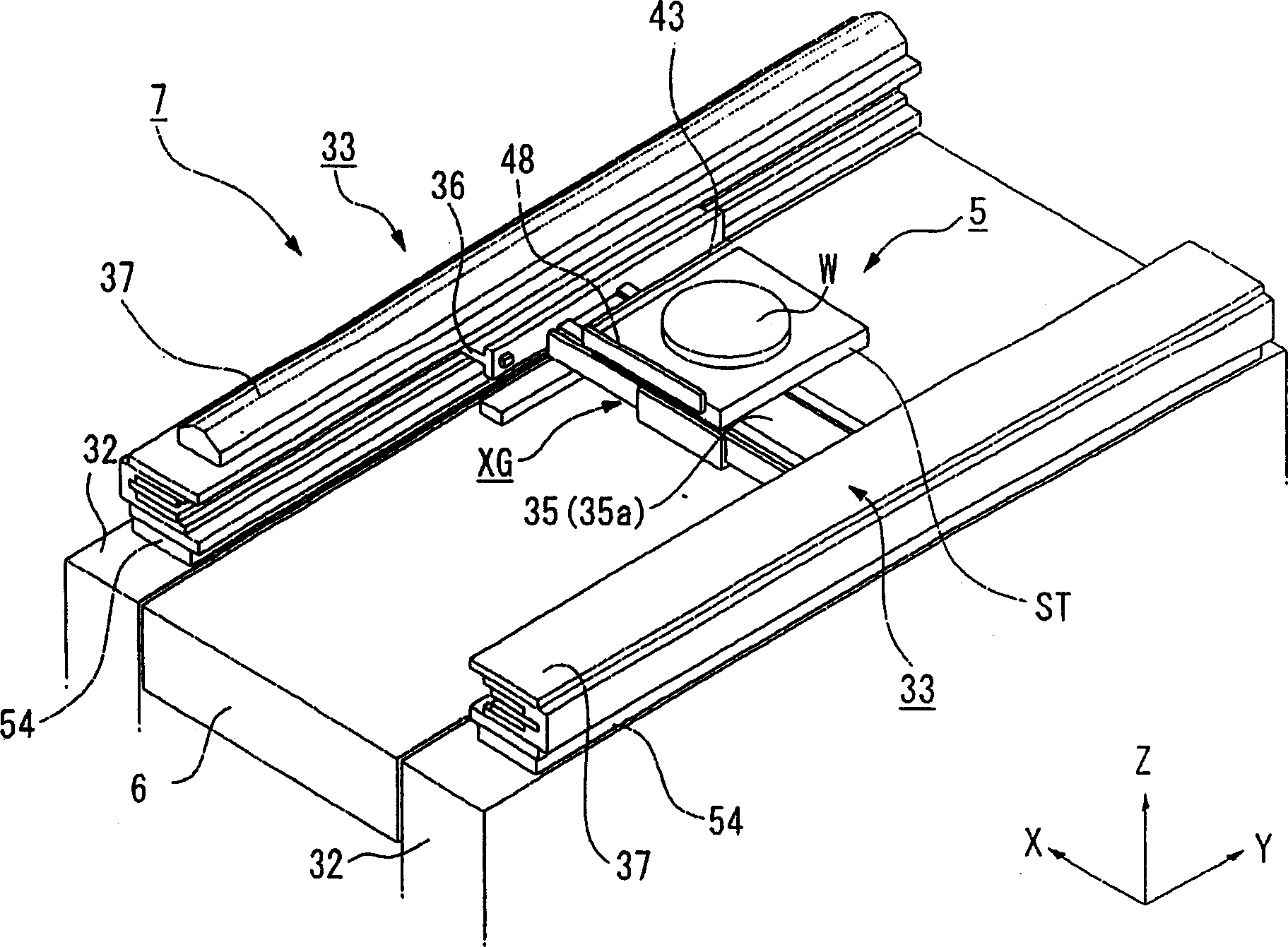

[0142] Refer to the following Figure 1 to Figure 14 Embodiments of the support device and its manufacturing method, stage device, and exposure device of the present invention will be described.

[0143] For example, an exposure apparatus will be described using an example in which a scanning type sequential exposure apparatus is used to transfer a circuit pattern of a semiconductor element formed on the reticle to a wafer while moving the reticle in synchronization with the wafer. Also, in this exposure apparatus, the supporting device of the present invention is applied to support the anti-vibration member of the projection optical system via the barrel platen. In these diagrams, pairs and shown as conventional examples Figure 15 The same constituent elements are assigned the same symbols and descriptions thereof are omitted.

[0144] figure 1 The exposure device shown is roughly composed of an illumination optical system IU that illuminates a rectangular (or arc-shaped)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com