Production method iron-base composite material and hard metal using high current

A technology of iron-based composite materials and hard alloys, which is applied in the field of high-current preparation of iron-based composite materials and hard alloys, can solve the problems of time-consuming and energy-consuming, and achieve the effect of high relative density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The examples given below are specific descriptions and further explanations of the present invention, and should not be construed as limiting the scope of protection of the present invention. Some non-essential improvements and adjustments made to the present invention by those skilled in the art based on the above-mentioned content of the present invention still belong to The scope of protection of the present invention.

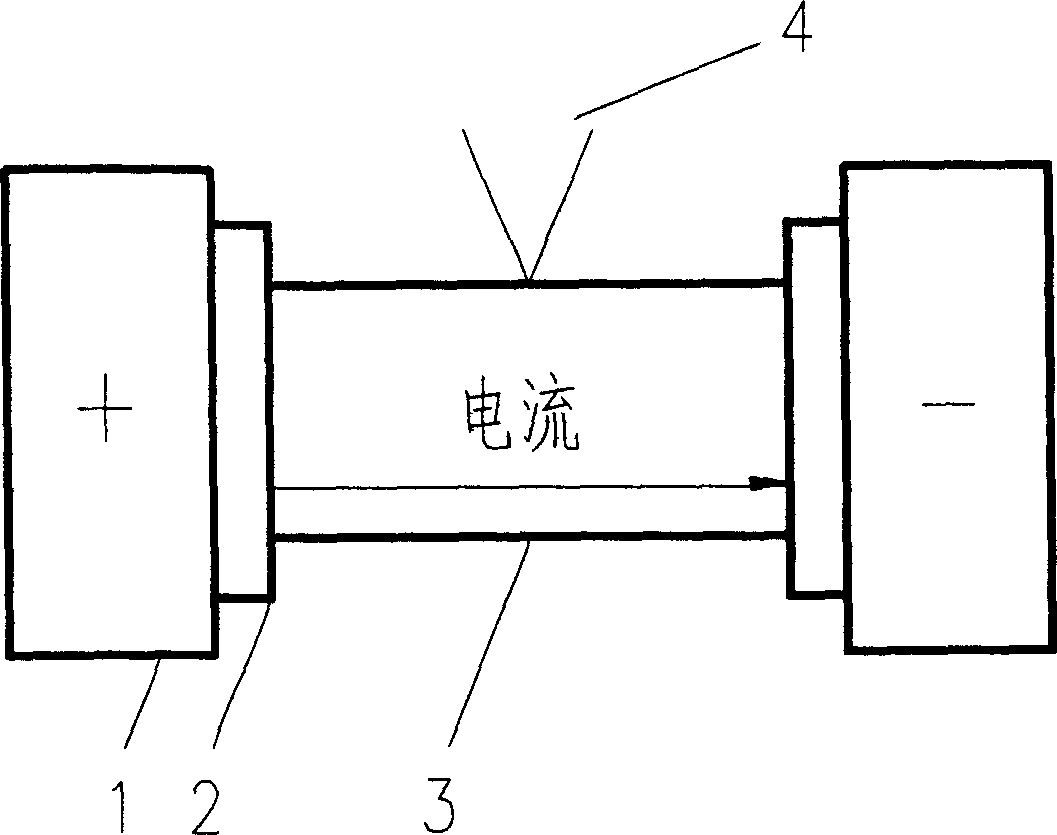

[0024] The implementation equipment used in the present invention is the Gleeble-1500D thermal simulator developed by the United States DSI Technology Consortium, and the equipment is composed of a vacuum system, a computer control system, and a heating system. The schematic diagram of the state where the compact is clamped and heated in the heating system is as follows: figure 1 Shown. The programming is controlled by a computer system according to the process conditions determined by the composition of the material to be prepared.

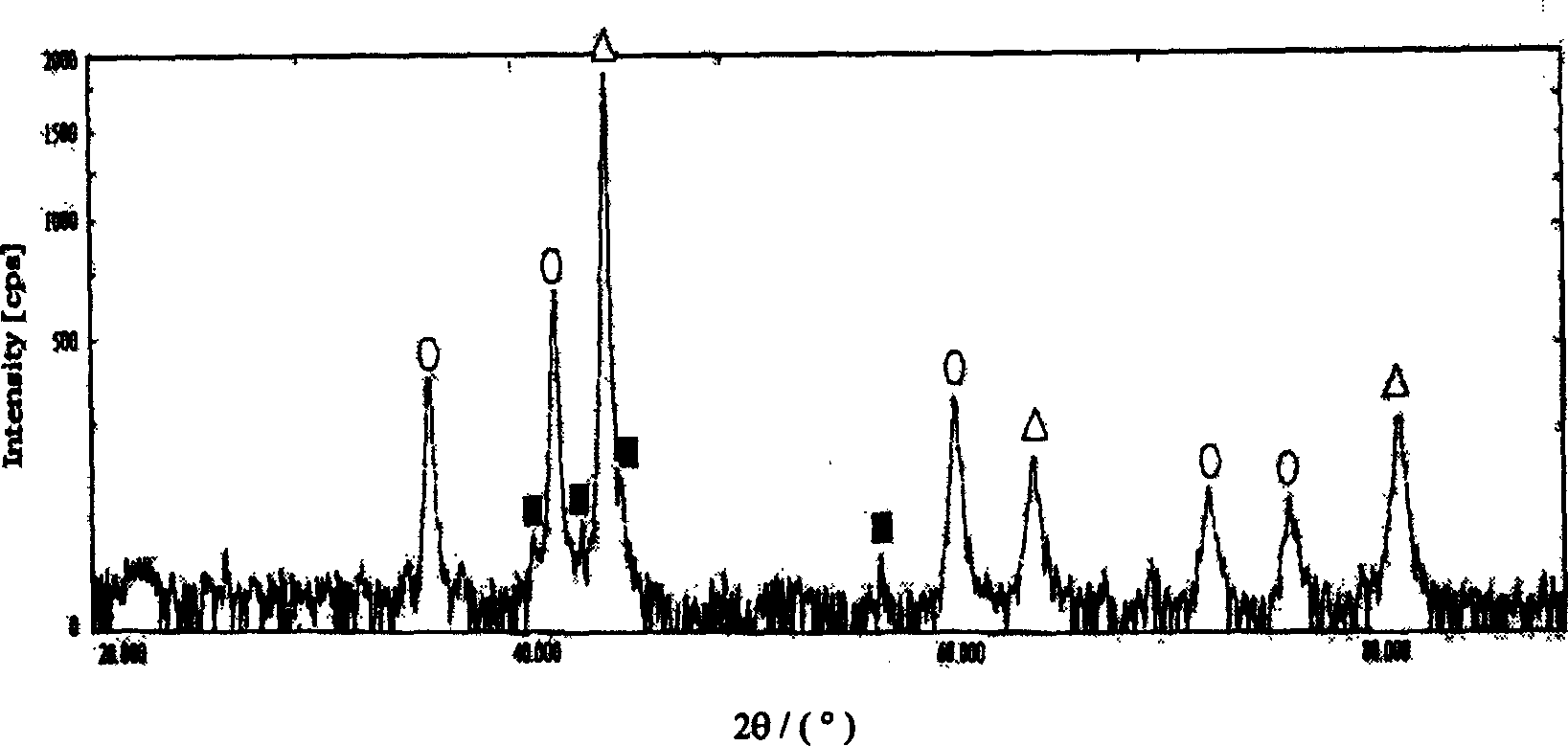

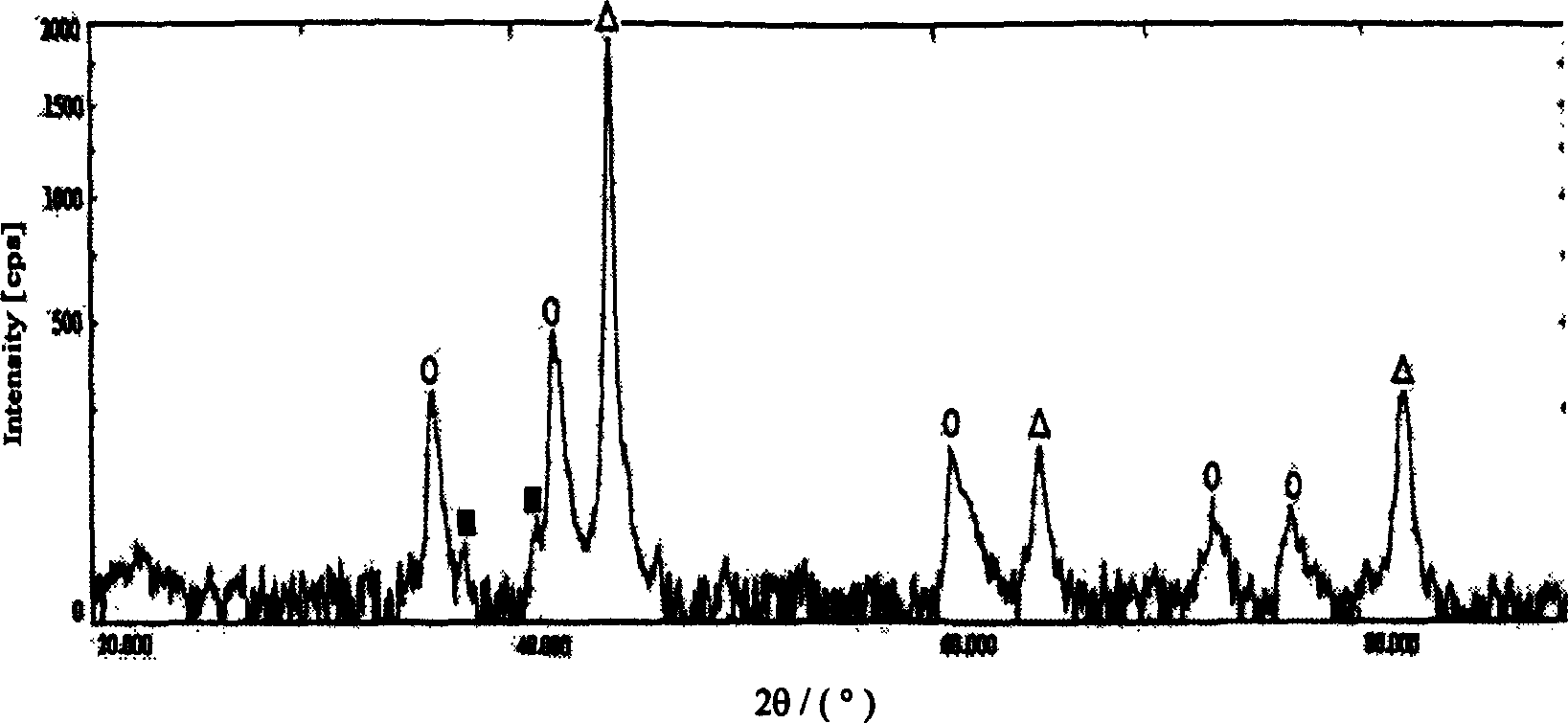

[0025] The specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com