Material, article and method of preparing materials containing oriented anisotropic particles

An anisotropic and particle technology, applied in the field of material and product preparation, can solve the problems of inability to achieve easy and efficient production, difficult continuous mode, slow and troublesome, etc., and achieve the effect of simple and economical preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0116] Example 4 - Clay Particles in Conductive Polymer:

[0117] A nanocomposite similar to Example 1 was prepared using Cloisite Na and the conductive polymer Baytron P (poly(3,4-ethylenedioxythiophene styrenesulfonate), supplied by Bayer Corporation). The weight ratio of clay:Baytron P in the final composition was maintained at 75:25. It should be noted that Baytron P is a known intercalation clay, as described in US 6,025,119.

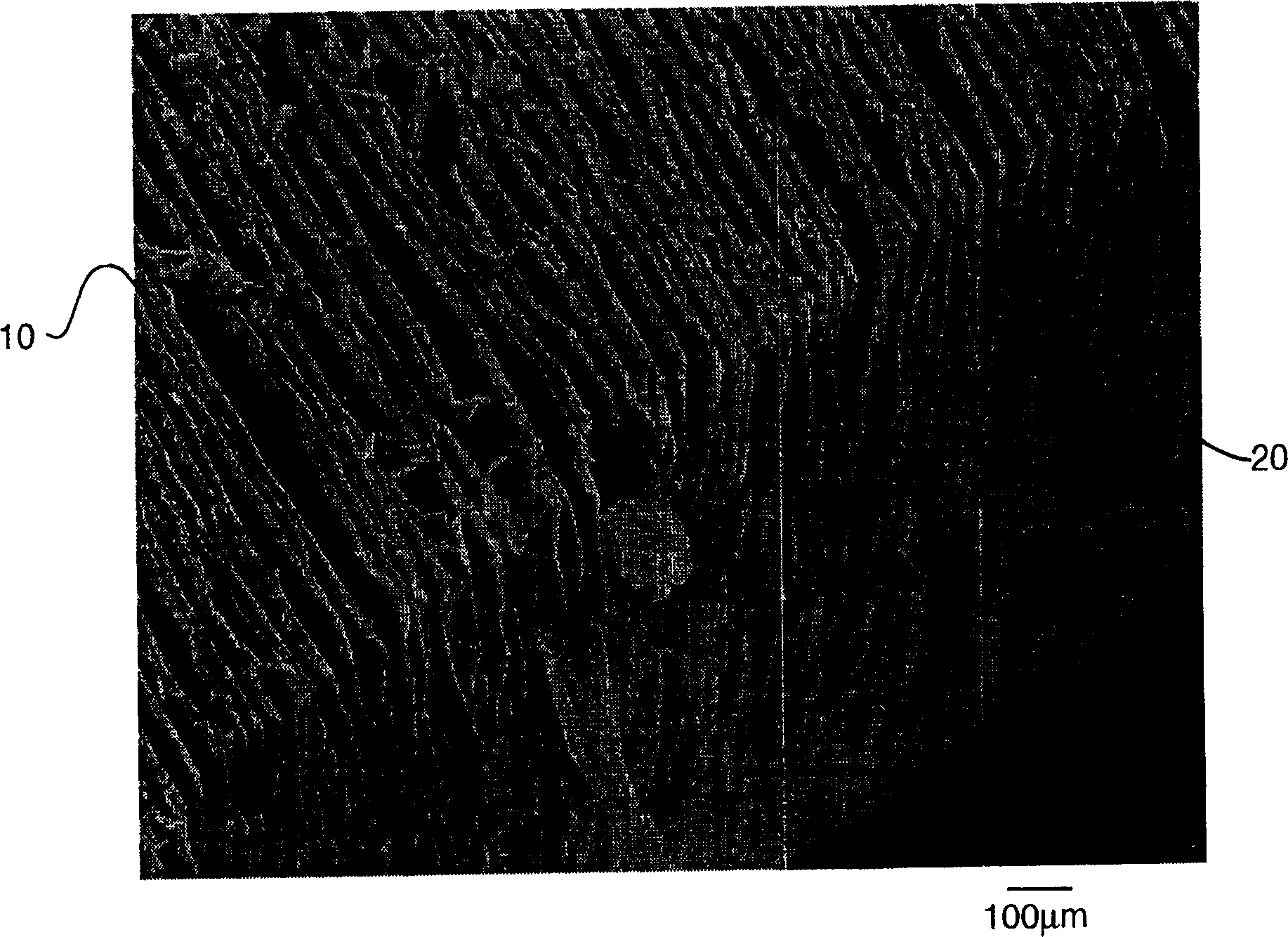

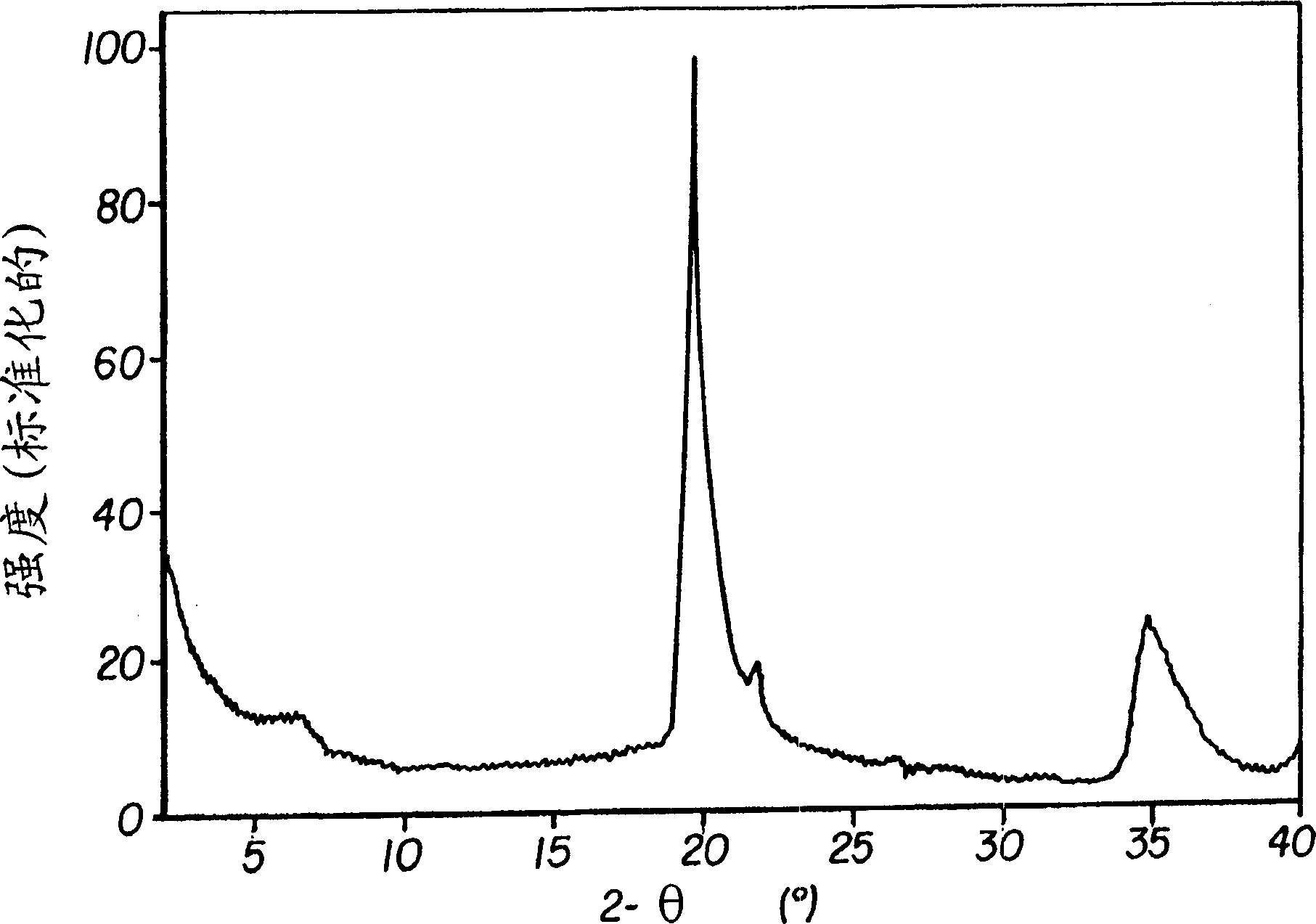

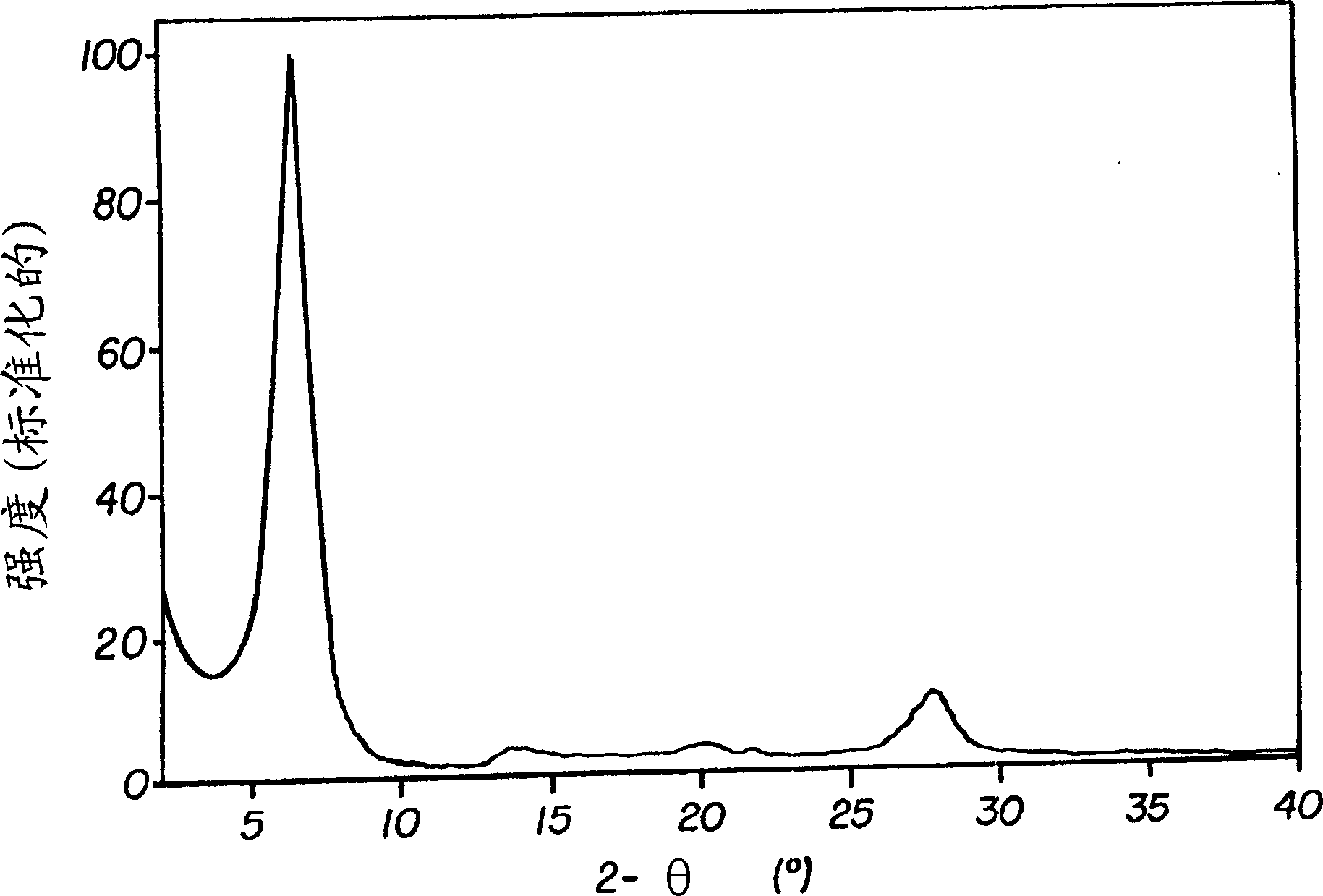

[0118] X-ray diffraction patterns of clay-polymer nanocomposites were recorded from two different sample orientations. Figure 5a In , data were collected for a surface that grew parallel to the substrate hit by the incident X-ray beam, Figure 5b In , data were collected for surfaces that grew in a direction perpendicular to the substrate hit by the incident X-ray beam. according to Figure 5a control Figure 5b The observed relative differences in the peak height intensities of the diffraction peaks clearly show an anisotropic arrangement of...

Embodiment 5

[0122] Example 5 - AgBr particles in gelatin:

[0123] Aqueous dispersion-type nanocomposites were prepared with flat sheets of AgBr and gelatin supplied by Eastman Kodak Company. The silver content was 1.55 mol Ag / kg emulsion and the gelatin polymer content was 40 g gelatin / mol Ag. The AgBr:gelatin nanocomposites were lyophilized in a Virtis Freezemobile 25ES with a Unitop 600L unit.

[0124] The X-ray diffraction patterns of AgBr:polymer nanocomposites were recorded from two different sample orientations. Figure 6a In , data were collected for a surface that grew parallel to the substrate hit by the incident X-ray beam, Figure 6b In , data were collected for surfaces that grew in a direction perpendicular to the substrate hit by the incident X-ray beam. according to Figure 6a control Figure 6b The relative differences in the peak height intensities of the observed diffraction peaks clearly indicate that the tabular AgBr particles exhibit anisotropic alignment. The ...

Embodiment 6

[0128] Example 6 - Cloisite Na clay particles dispersed in water:

[0129] Cloisite Na (a commercial grade montmorillonite clay supplied by Southern Clay Products) was formulated as an aqueous dispersion at 2 wt% solids. The final composition was stirred for at least 12 hours and then lyophilized in a Virtis Freezemobile 25ES with a Unitop 600L unit.

[0130] X-ray diffraction patterns of freeze-dried clay were recorded from two different sample orientations. Figure 7a In , data were collected for a surface that grew parallel to the substrate hit by the incident X-ray beam, Figure 7b In , data were collected for surfaces that grew in a direction perpendicular to the substrate hit by the incident X-ray beam. according to Figure 7a control Figure 7b The observed relative differences in the peak height intensities of the diffraction peaks clearly show an anisotropic arrangement of the clay platelets. The observed variation of the relative intensity of the diffraction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com