High-stability fast-erasing patterned polymer memory and preparation method thereof

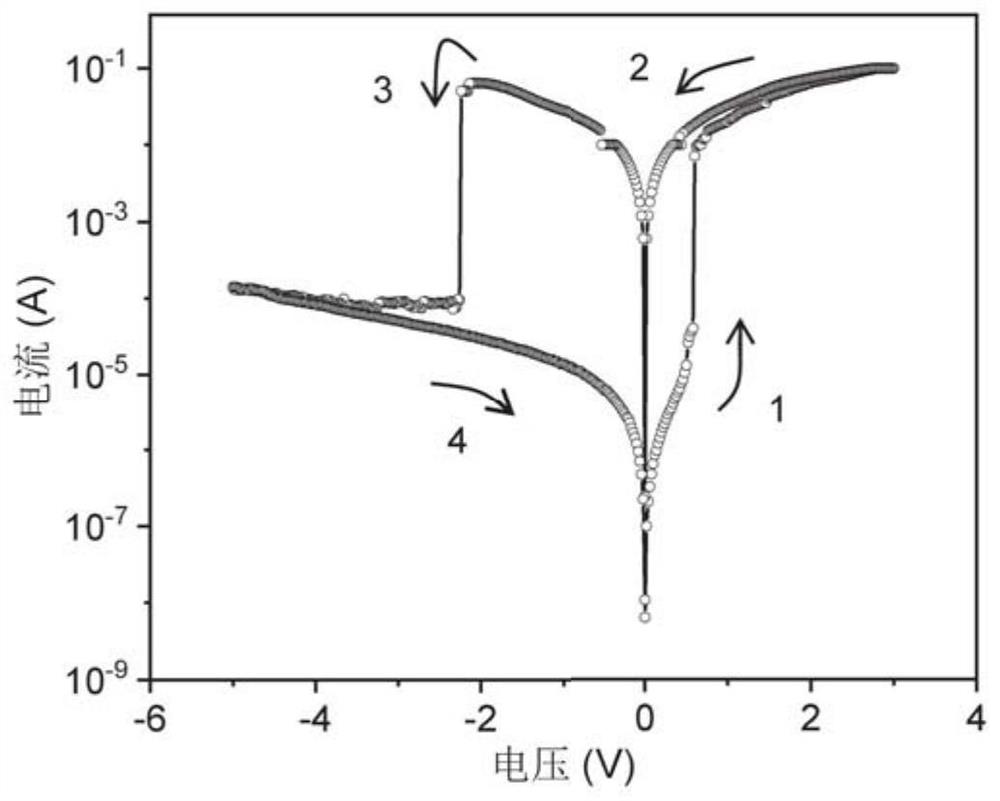

A patterning and memory technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as memory device failure, instability, and obstacles to the practical application of polymer memory technology, and achieve erasing and writing speeds Fast, easy to obtain raw materials, simple and economical preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

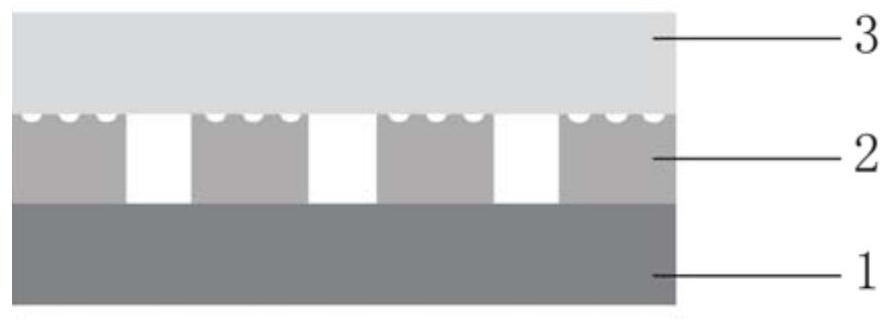

[0047] A preparation method of a highly stable flash write patterned polymer memory, comprising the following steps:

[0048] (1) Conductive substrate treatment: The ITO substrate was ultrasonicated for 15 minutes with deionized water, ethanol, and isopropanol, respectively, and dried with nitrogen gas.

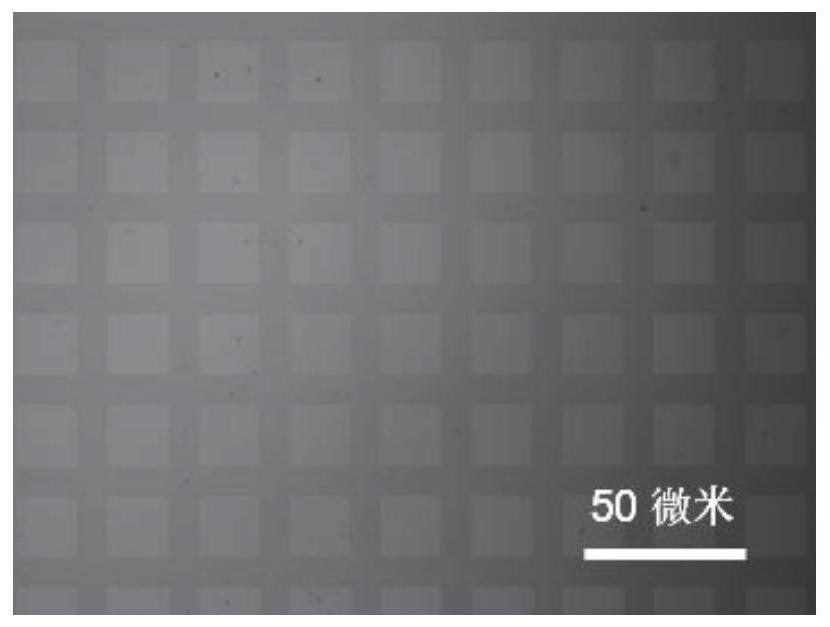

[0049] (2) 4,4'-bis(9-carbazole)biphenyl was dissolved in chlorobenzene to obtain a 0.1mol / L solution, and it was spin-coated on the ITO substrate at a speed of 2500r / min, and then Put it in the water vapor condition of 80% humidity environment for 30 minutes, take it out, then add a square mask on the monomer film, and finally place it under the light source for reaction, control the reaction temperature at 50°C, and the reaction time for 2 hours After the reaction, the sample is cleaned to obtain a square patterned polymer with surface holes grown on the ITO substrate, which is a storage medium layer with a thickness of 25nm, and the diameter and depth of the surface holes ar...

Embodiment 2

[0057] A preparation method of a highly stable flash write patterned polymer memory, comprising the following steps:

[0058] (1) Conductive substrate treatment: The ITO substrate was ultrasonicated for 15 minutes with deionized water, ethanol, and isopropanol, respectively, and dried with nitrogen gas.

[0059] (2) Dissolve 1,3,5-tri(9H-carbazol-9-yl)benzene in dichloromethane to obtain a 0.5mol / L solution, and spin-coat it on the ITO substrate at a speed of 3000r / min Then place it in the water vapor condition of 50% humidity environment for 60min and then take it out, then add a circular mask on the monomer film, and finally put it under the light source for reaction, control the reaction temperature to 75 ℃, the reaction time is 1.5 hours, after the reaction, the sample is cleaned to obtain a circular patterned polymer with surface holes grown on the ITO substrate, which is a storage medium layer with a thickness of 20nm, and the diameter and depth of the surface holes are ...

Embodiment 3

[0065] A preparation method of a highly stable flash write patterned polymer memory, comprising the following steps:

[0066] (1) Conductive substrate treatment: The ITO substrate was ultrasonicated for 15 minutes with deionized water, ethanol, and isopropanol, respectively, and dried with nitrogen gas.

[0067] (2) Dissolve benzotrithiophene in toluene to obtain a 1mol / L solution, and spin-coat it on an ITO substrate at a speed of 4000r / min, and then place it in a water vapor condition in a 30% humidity environment Take it out after standing for 90 minutes, then add an elliptical mask on the monomer film, and finally place it under a light source for reaction, control the reaction temperature at 25°C, and the reaction time for 3 hours. After the reaction, wash the sample to obtain growth The elliptical polymer with surface holes on the ITO substrate is a storage medium layer with a thickness of 30nm, and the diameter and depth of the surface holes are 150nm and 6nm respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com