Preparation method for intensive pulse light treated cumaldehyde/tetra-lysine antibacterial agent

A technology of pulsed strong light and tetralysine, which is applied in the directions of botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of sterilization and fresh-keeping biofilms being difficult to remove, and achieves a simple and economical preparation method, good effect and large scale. The effect of development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

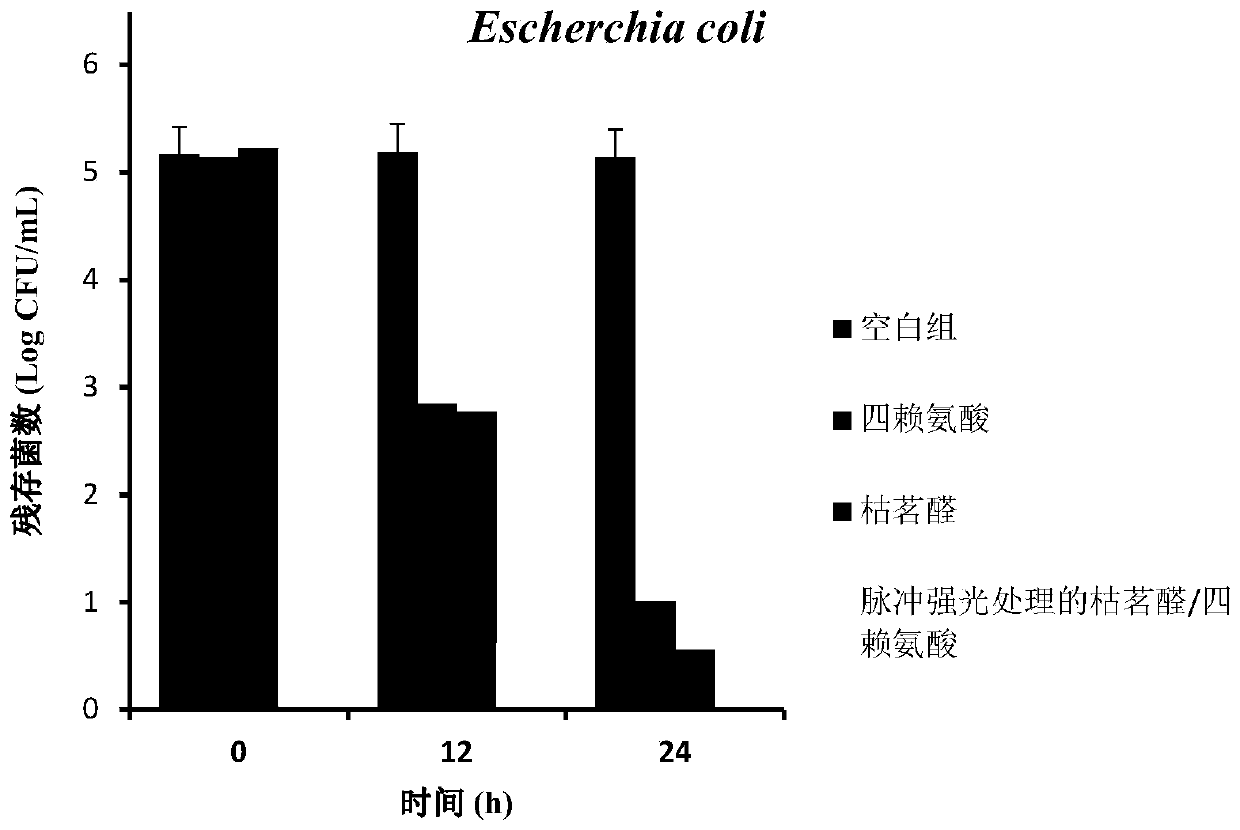

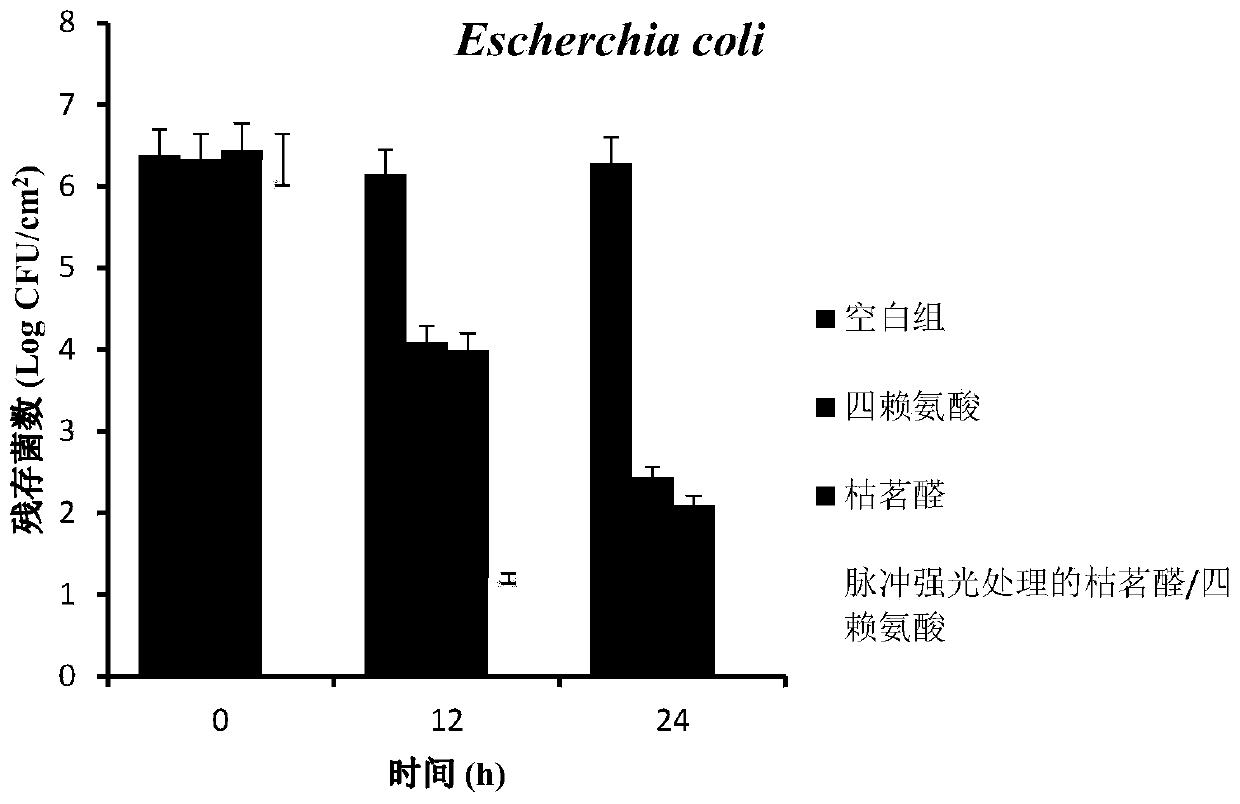

[0018] The antibacterial effect of cuminaldehyde / tetralysine antibacterial agent of embodiment 1 pulsed strong light treatment on escherichia coli (E.coli) and escherichia coli biofilm

[0019] 1 experimental bacteria

[0020] Foodborne pathogens: Escherichia coli

[0021] 2 experimental equipment

[0022] Vertical Pressure Steam Sterilizer HVE50 Japan Hirayama Co., Ltd.

[0023] Biochemical incubator LRH Shanghai Yiheng Scientific Instrument Co., Ltd.

[0024] 3 Experimental methods

[0025] 1) Antibacterial effect of cuminaldehyde / tetralysine antibacterial agent treated with pulsed strong light on Escherichia coli in vitro

[0026] ① Escherichia coli was inoculated in nutrient broth liquid medium, cultured at 37°C with shaking (150rpm) for 24 hours to obtain Escherichia coli in logarithmic growth phase.

[0027] ② Dilute Escherichia coli in the logarithmic growth phase and add them to 5mL sterile phosphate buffer to make the concentration of Escherichia coli 10 4 -10 ...

Embodiment 2 4

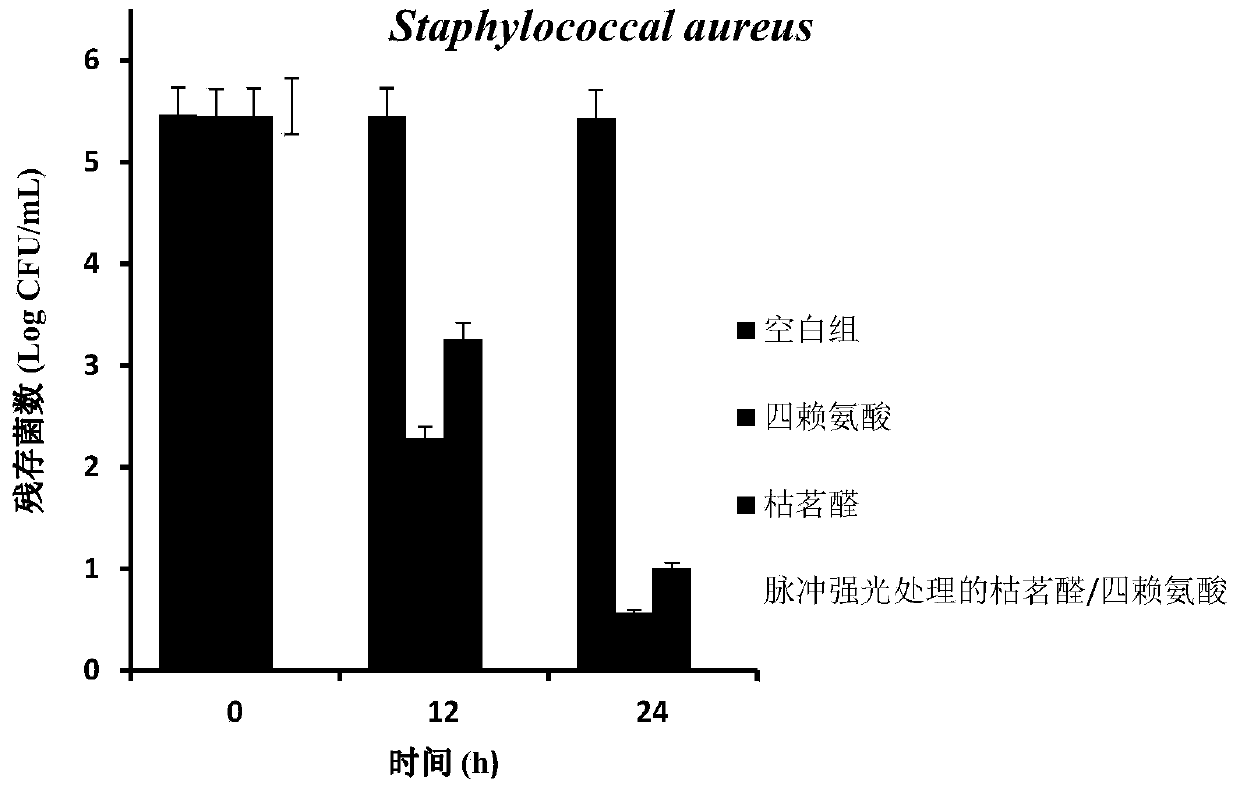

[0036] Embodiment 2 Tetralysine is to the antibacterial effect of Staphylococcus aureus (S.aureus) and Staphylococcus aureus biofilm

[0037] 1 experimental bacteria

[0038] Staphylococcus aureus (S.aureus)

[0039] 2 Experimental methods

[0040] 1) Antibacterial effect of cuminaldehyde / tetralysine antibacterial agent treated with pulsed strong light on S.aureus in vitro

[0041] ①S.aureus was inoculated in nutrient broth liquid medium, and cultured with shaking (150rpm) at 37°C for 48 hours to obtain Staphylococcus aureus (S.aureus) in logarithmic growth phase.

[0042] ② Add S.aureus in the logarithmic growth phase to sterile phosphate buffer, and dilute to 10 4 -10 5 CFU / mL, and then add the same amount of cuminaldehyde / tetralysine antibacterial agent, tetralysine, and cuminaldehyde treated with pulsed strong light respectively.

[0043] ③Cultivate the bacterial suspension added with antibacterial agent at 37°C for 24 hours, and then use the plate count method to det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com