Two-stage immersion combustion evaporation process for treating percolate from filling field

A technology of immersion combustion evaporation and leachate, which is applied in heating water/sewage treatment and other directions, can solve the problems of difficult exhaust gas and low energy utilization rate, and achieve the effects of reducing pollution, saving energy and improving heat transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

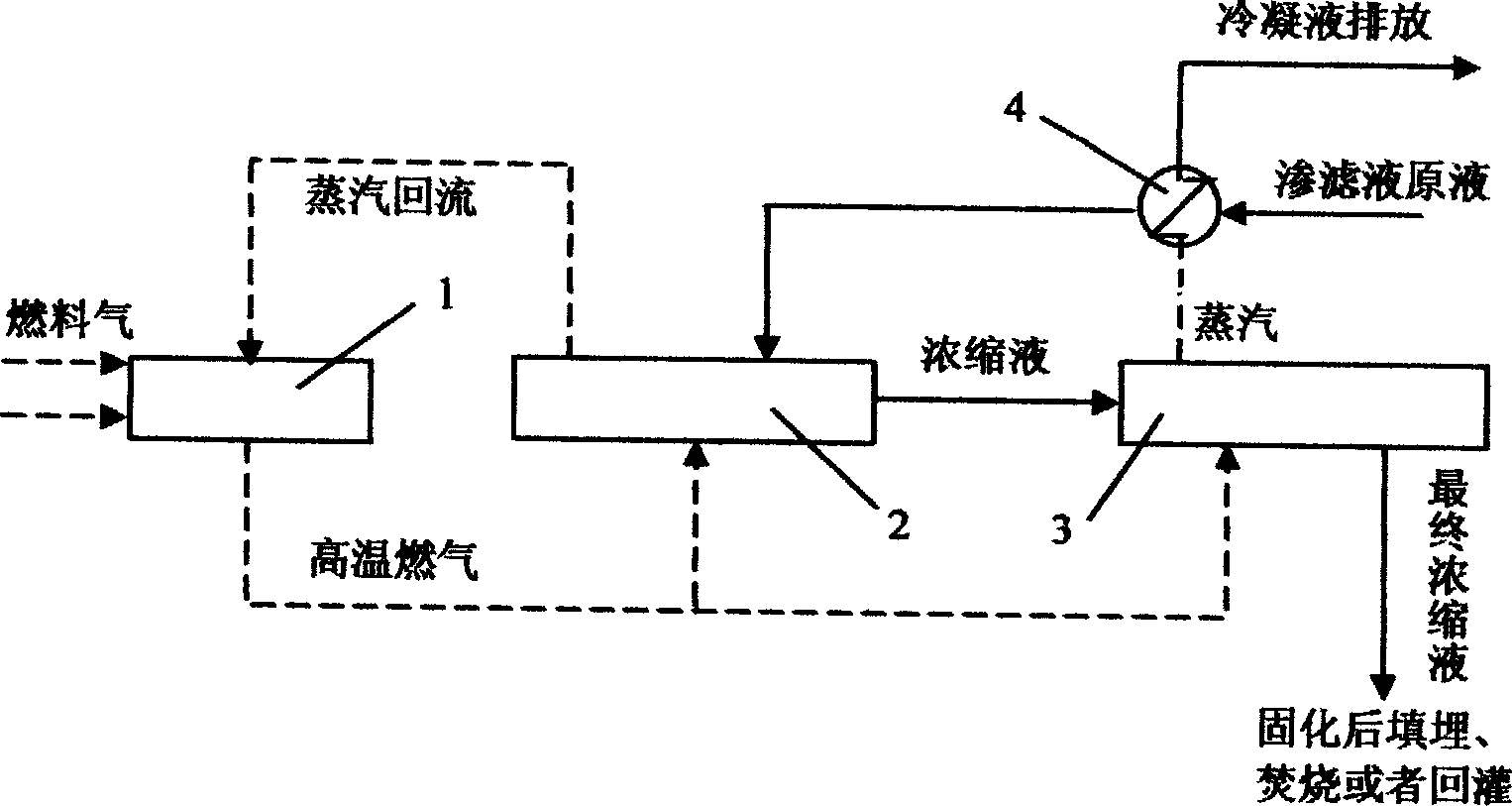

[0008] The invention is an economical, efficient and energy-saving two-stage landfill leachate immersion combustion evaporation process, the process flow is as follows figure 1 The specific steps shown are: firstly, the leachate raw liquid or the pre-treated leachate concentrate, after preliminary filtration, enters the evaporation unit 2 of the first stage from the heat exchanger 4, and uses landfill gas or other commercial fuels as the Energy, the high-temperature gas (750-850°C) produced by the combustion of the gas burner 1 enters the leachate in the first-stage evaporation unit 2 and the second-stage evaporation unit 3 respectively, and the released heat evaporates and concentrates the leachate In the first stage, the steam generated by the evaporation unit 2 flows back into the gas burner 1, and is incinerated at 750-850°C to evaporate the volatile organic compounds in the leachate, and return to the gas burner to destroy the organic components through incineration, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com